Water uptake, moisture absorption and wettability of beech veneer treated with N-Methylol melamine compounds and alkyl ketene dimer

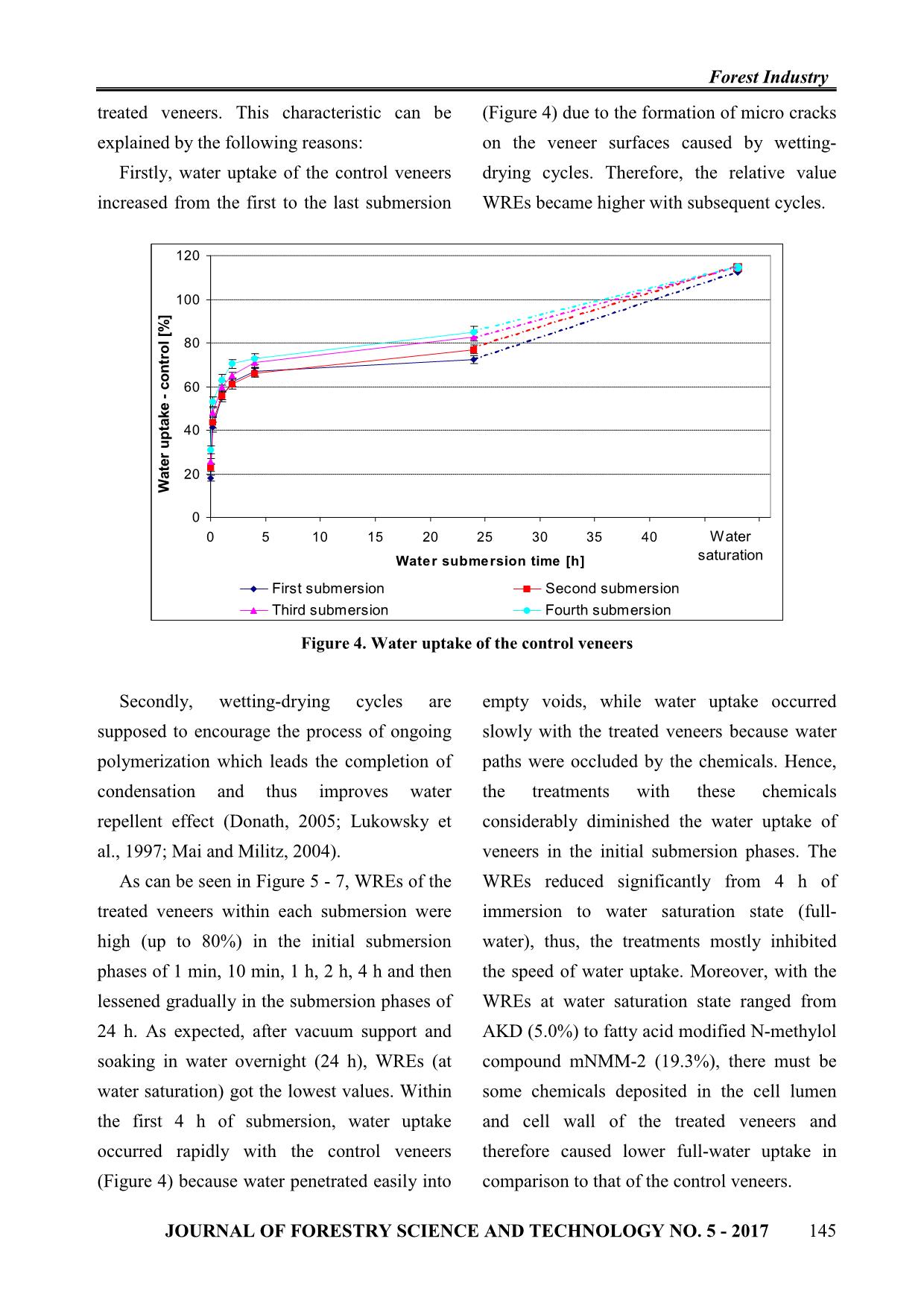

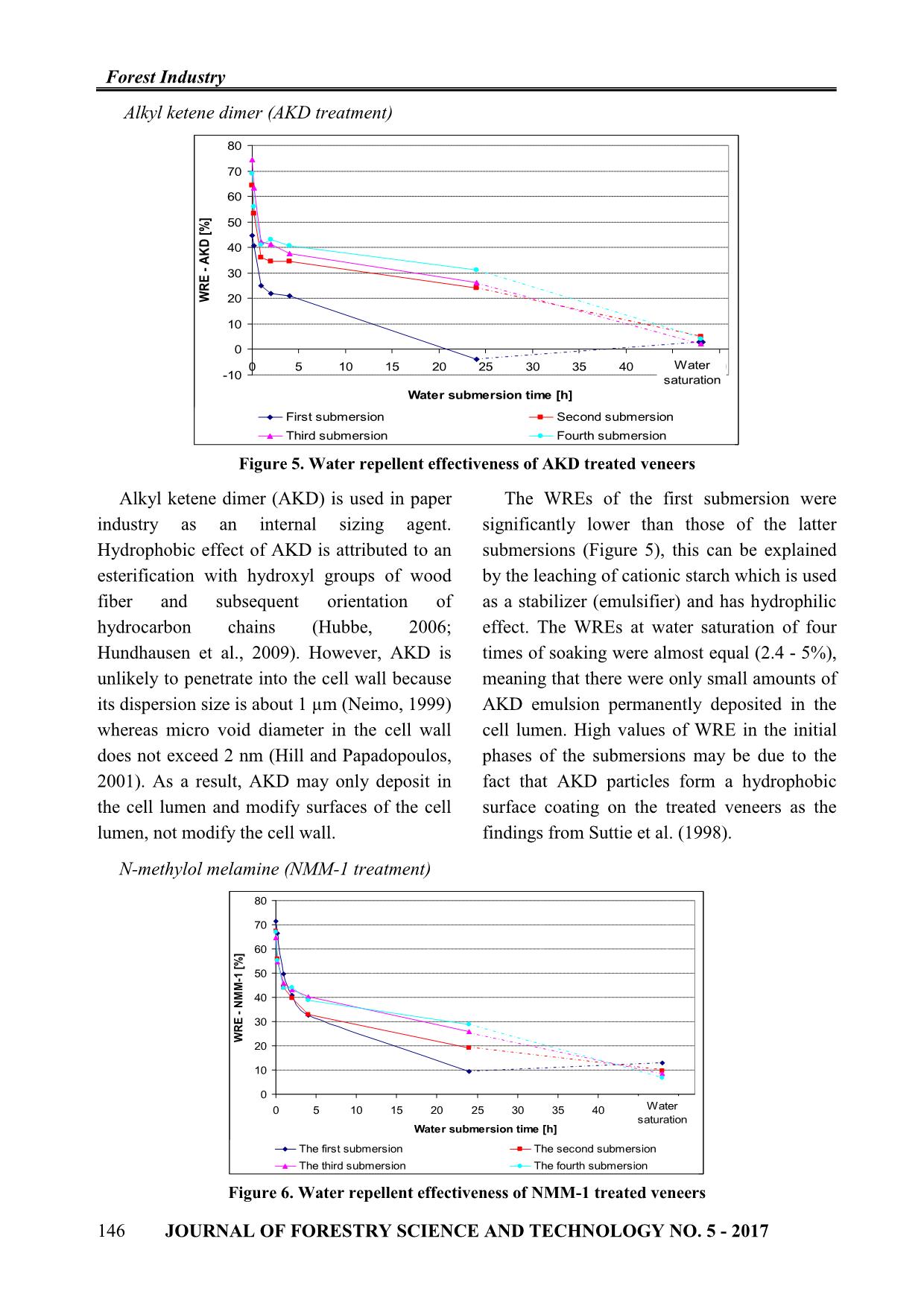

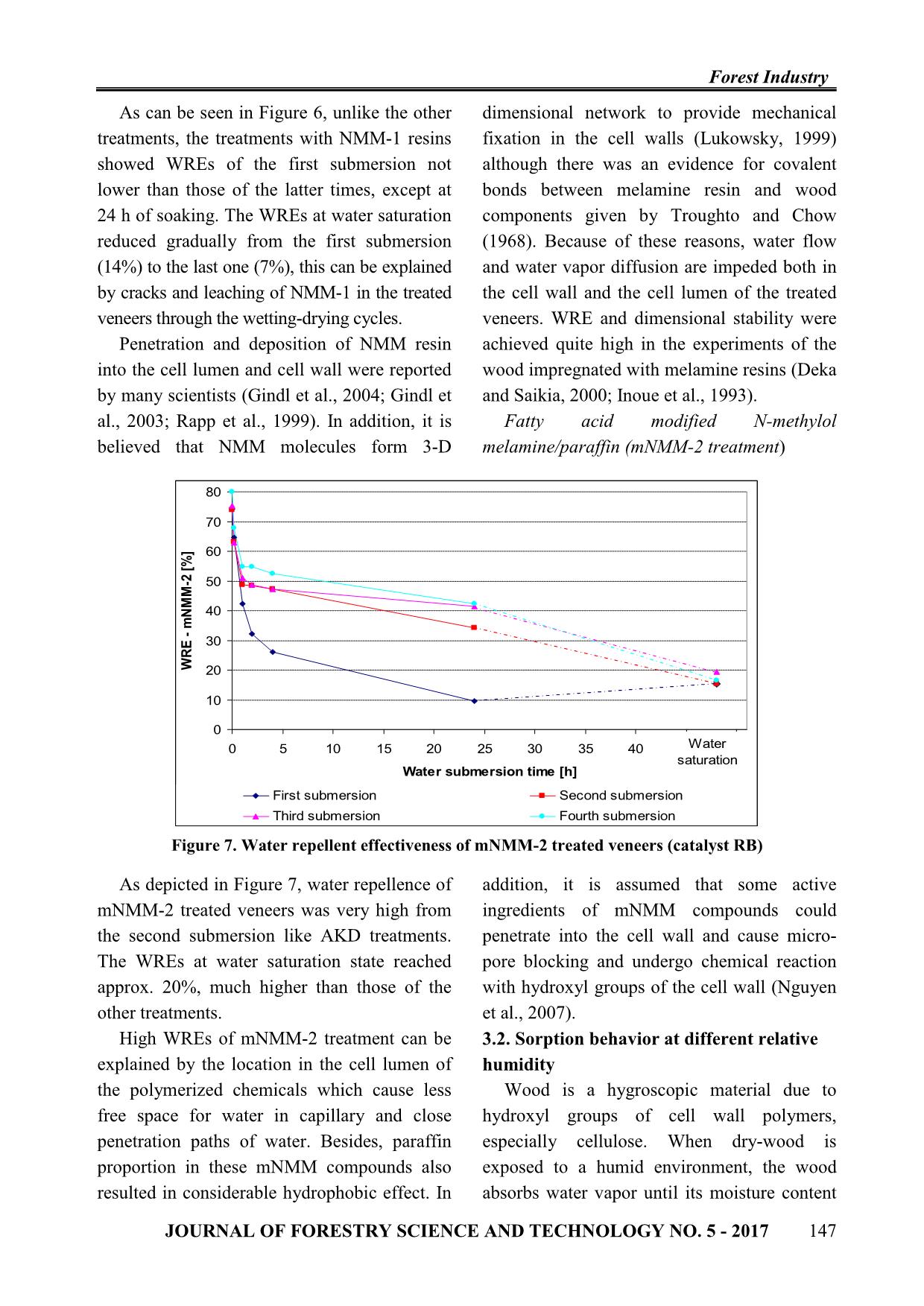

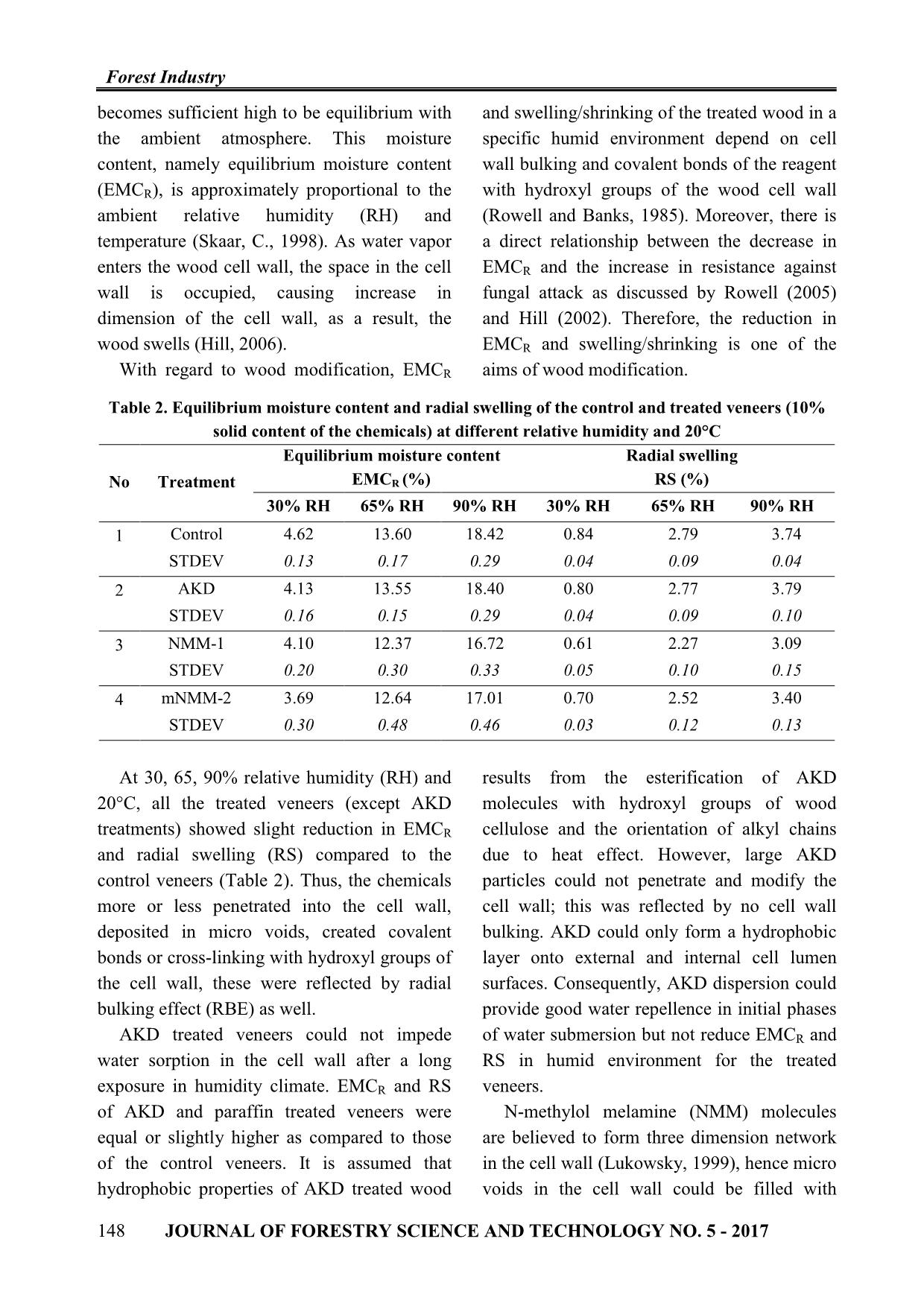

With Beech veneers being treated with 10% solid content of the chemicals from paper (Alkyl ketene dimer, AKD), wood (N-Methylol melamine, NMM-1) and textile industry (fatty acid modified N-methylol melamine, mNMM-2), the results showed that the treatments with these chemicals considerably increased the water repellence effectiveness (WRE) of veneers in the initial submersion phases; Then, WREs reduced significantly from 4 h of immersion to water saturation state (full-water). Moreover, with the WREs at water saturation state ranged from AKD (5.0%) to mNMM-2 (19.3%), there must be some certain chemical deposited in the cell lumen and cell wall of the treated veneers. The water repellence of the treated veneers was stable after the wetting-drying cycles. The chemicals NMM-1 and mNMM-2 that could react with hydroxyl groups or deposit into the cell wall, may induce the reduction in equilibrium moisture content (EMCR) and radial swelling (RS) for the treated veneers, while large AKD particles could not penetrate and modify the cell wall therefore did not reduce EMCR and RS in humid environment for the treated veneers. Wettability of veneers treated with AKD, NMM-1 and mNMM-2 was much lower than the untreated and control veneers

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

Tóm tắt nội dung tài liệu: Water uptake, moisture absorption and wettability of beech veneer treated with N-Methylol melamine compounds and alkyl ketene dimer

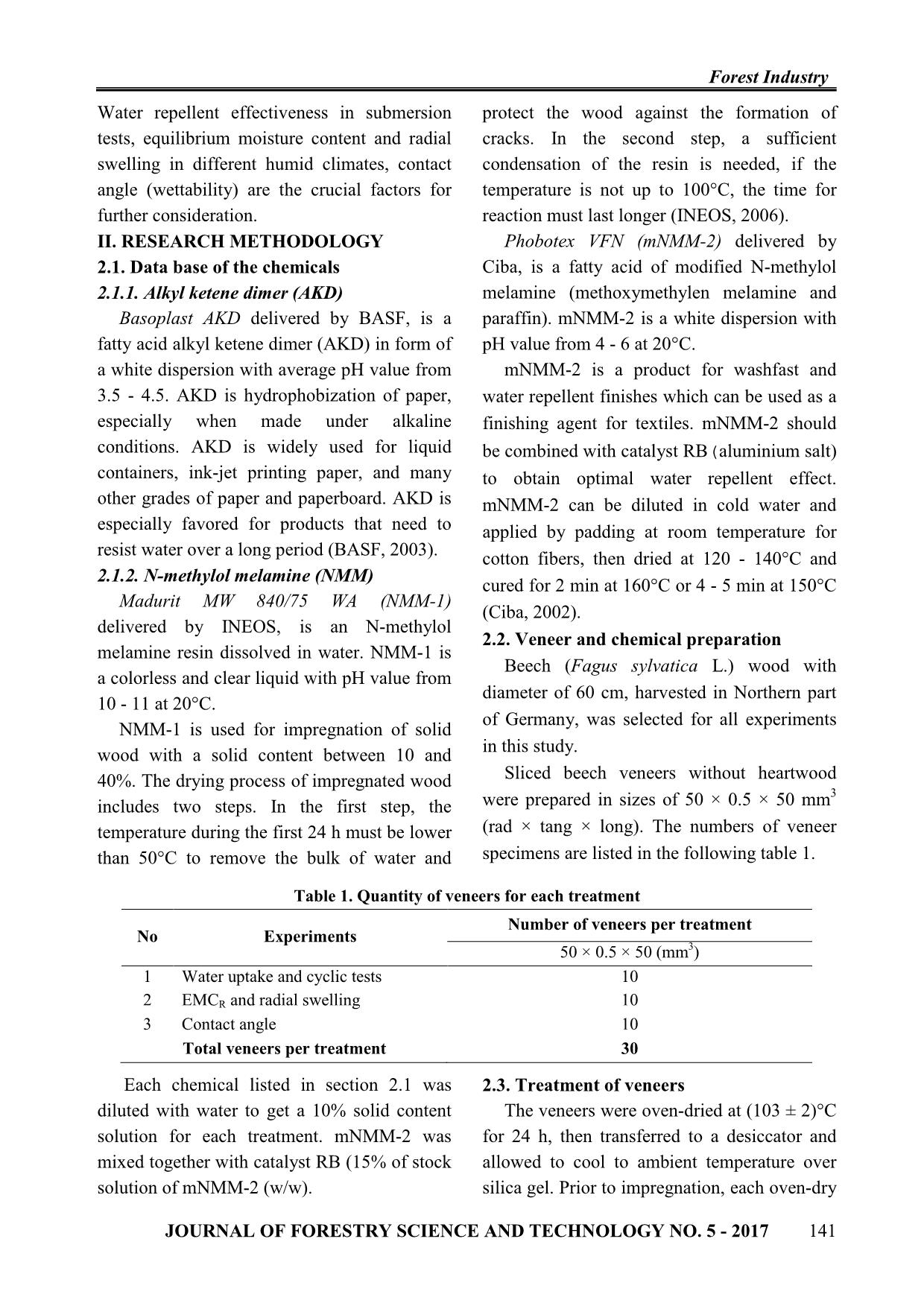

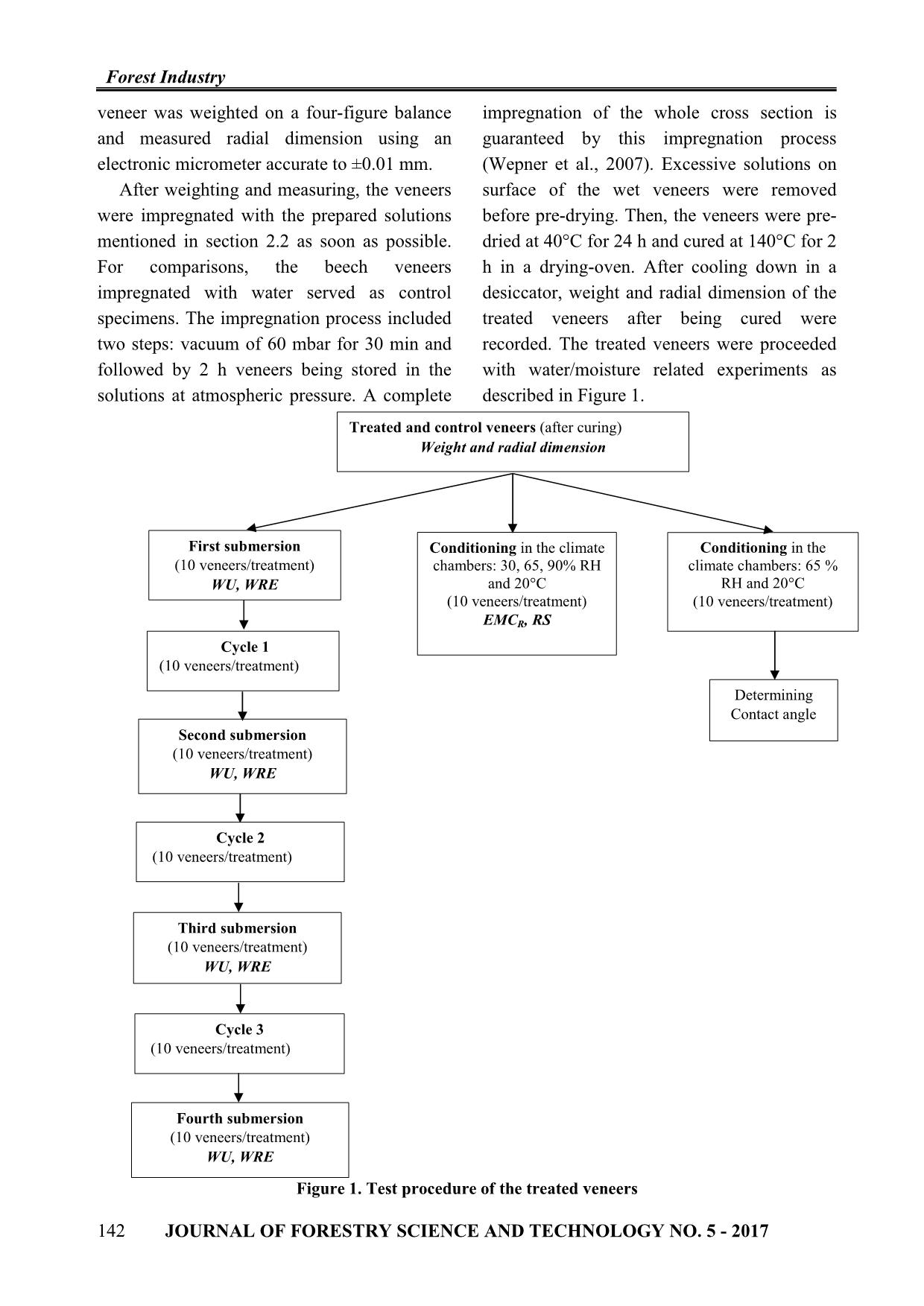

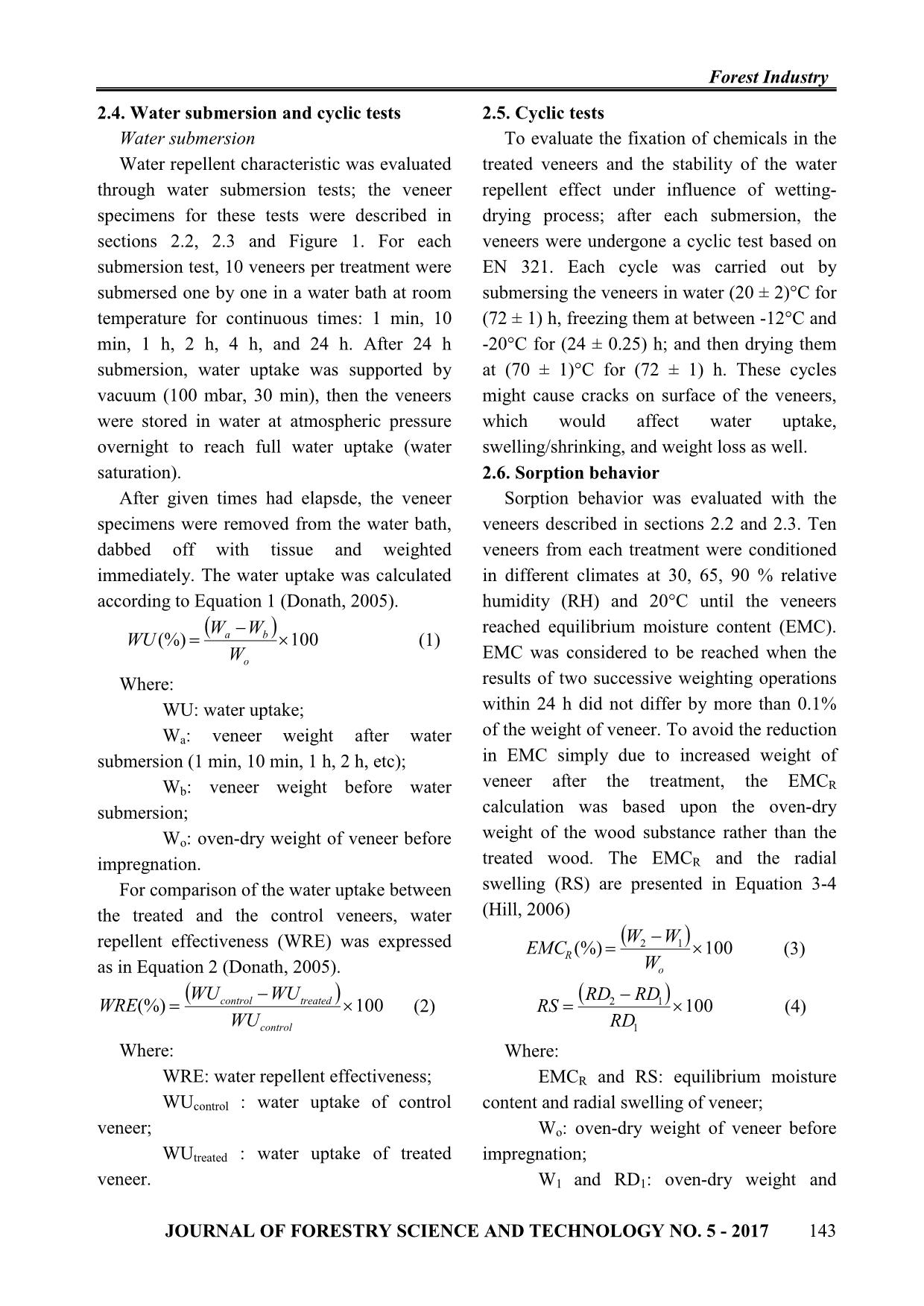

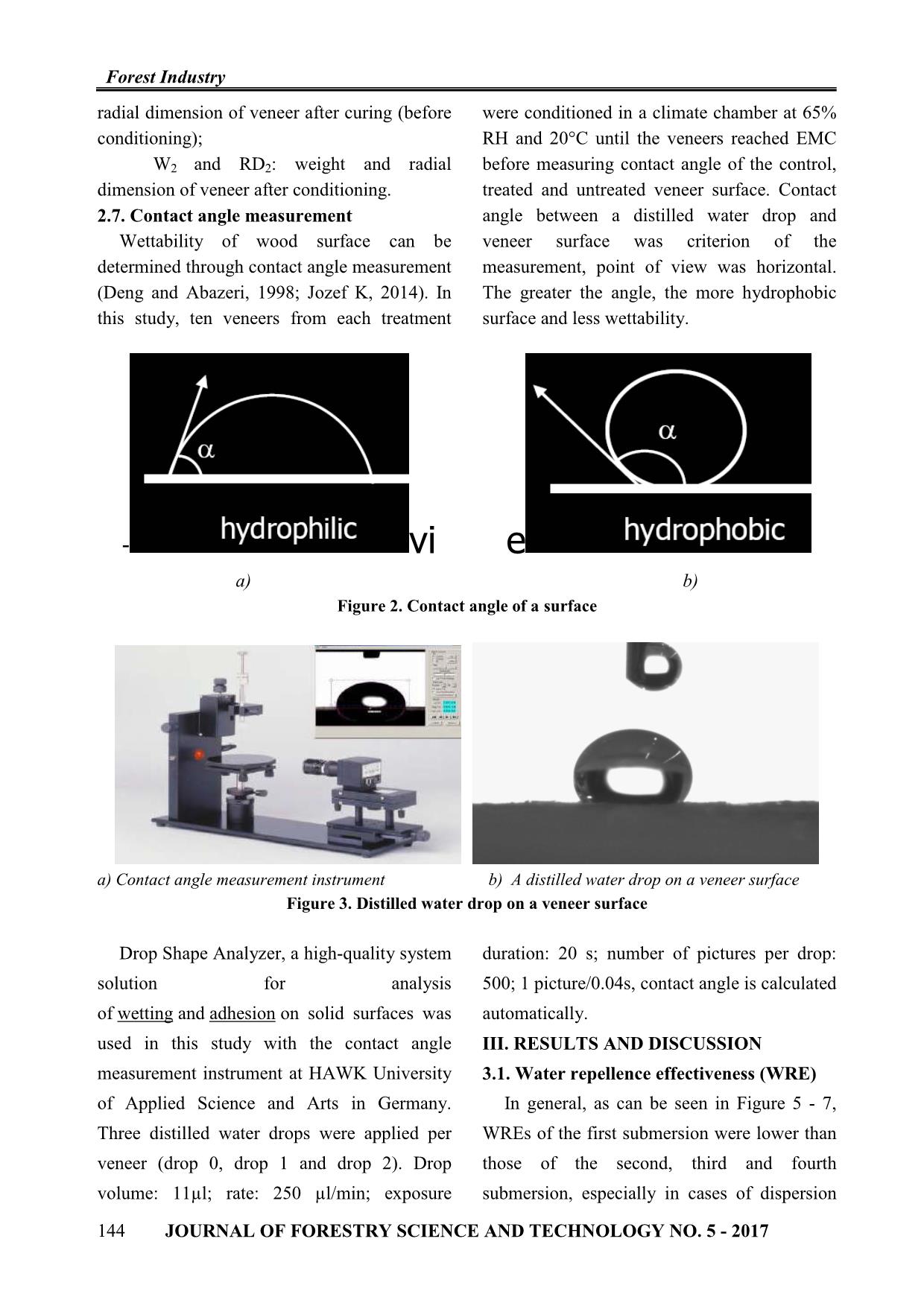

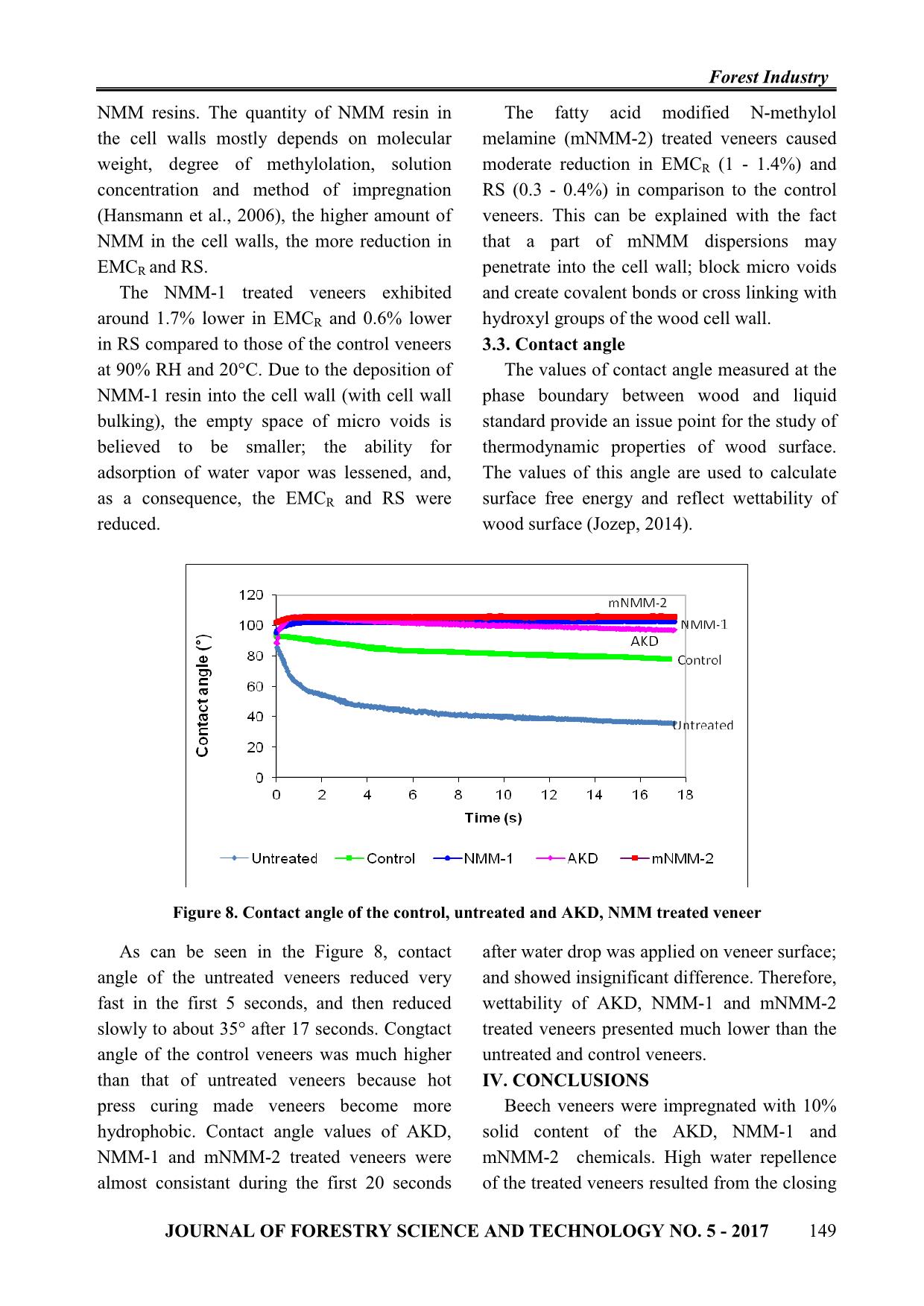

chemical reaction approx. 20%, much higher than those of the with hydroxyl groups of the cell wall (Nguyen other treatments. et al., 2007). High WREs of mNMM-2 treatment can be 3.2. Sorption behavior at different relative explained by the location in the cell lumen of humidity the polymerized chemicals which cause less Wood is a hygroscopic material due to free space for water in capillary and close hydroxyl groups of cell wall polymers, penetration paths of water. Besides, paraffin especially cellulose. When dry-wood is proportion in these mNMM compounds also exposed to a humid environment, the wood resulted in considerable hydrophobic effect. In absorbs water vapor until its moisture content JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 147 Forest Industry becomes sufficient high to be equilibrium with and swelling/shrinking of the treated wood in a the ambient atmosphere. This moisture specific humid environment depend on cell content, namely equilibrium moisture content wall bulking and covalent bonds of the reagent (EMCR), is approximately proportional to the with hydroxyl groups of the wood cell wall ambient relative humidity (RH) and (Rowell and Banks, 1985). Moreover, there is temperature (Skaar, C., 1998). As water vapor a direct relationship between the decrease in enters the wood cell wall, the space in the cell EMCR and the increase in resistance against wall is occupied, causing increase in fungal attack as discussed by Rowell (2005) dimension of the cell wall, as a result, the and Hill (2002). Therefore, the reduction in wood swells (Hill, 2006). EMCR and swelling/shrinking is one of the With regard to wood modification, EMCR aims of wood modification. Table 2. Equilibrium moisture content and radial swelling of the control and treated veneers (10% solid content of the chemicals) at different relative humidity and 20°C Equilibrium moisture content Radial swelling No Treatment EMCR (%) RS (%) 30% RH 65% RH 90% RH 30% RH 65% RH 90% RH 1 Control 4.62 13.60 18.42 0.84 2.79 3.74 STDEV 0.13 0.17 0.29 0.04 0.09 0.04 2 AKD 4.13 13.55 18.40 0.80 2.77 3.79 STDEV 0.16 0.15 0.29 0.04 0.09 0.10 3 NMM-1 4.10 12.37 16.72 0.61 2.27 3.09 STDEV 0.20 0.30 0.33 0.05 0.10 0.15 4 mNMM-2 3.69 12.64 17.01 0.70 2.52 3.40 STDEV 0.30 0.48 0.46 0.03 0.12 0.13 At 30, 65, 90% relative humidity (RH) and results from the esterification of AKD 20°C, all the treated veneers (except AKD molecules with hydroxyl groups of wood treatments) showed slight reduction in EMCR cellulose and the orientation of alkyl chains and radial swelling (RS) compared to the due to heat effect. However, large AKD control veneers (Table 2). Thus, the chemicals particles could not penetrate and modify the more or less penetrated into the cell wall, cell wall; this was reflected by no cell wall deposited in micro voids, created covalent bulking. AKD could only form a hydrophobic bonds or cross-linking with hydroxyl groups of layer onto external and internal cell lumen the cell wall, these were reflected by radial surfaces. Consequently, AKD dispersion could bulking effect (RBE) as well. provide good water repellence in initial phases AKD treated veneers could not impede of water submersion but not reduce EMCR and water sorption in the cell wall after a long RS in humid environment for the treated exposure in humidity climate. EMCR and RS veneers. of AKD and paraffin treated veneers were N-methylol melamine (NMM) molecules equal or slightly higher as compared to those are believed to form three dimension network of the control veneers. It is assumed that in the cell wall (Lukowsky, 1999), hence micro hydrophobic properties of AKD treated wood voids in the cell wall could be filled with 148 JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 Forest Industry NMM resins. The quantity of NMM resin in The fatty acid modified N-methylol the cell walls mostly depends on molecular melamine (mNMM-2) treated veneers caused weight, degree of methylolation, solution moderate reduction in EMCR (1 - 1.4%) and concentration and method of impregnation RS (0.3 - 0.4%) in comparison to the control (Hansmann et al., 2006), the higher amount of veneers. This can be explained with the fact NMM in the cell walls, the more reduction in that a part of mNMM dispersions may EMCR and RS. penetrate into the cell wall; block micro voids The NMM-1 treated veneers exhibited and create covalent bonds or cross linking with around 1.7% lower in EMCR and 0.6% lower hydroxyl groups of the wood cell wall. in RS compared to those of the control veneers 3.3. Contact angle at 90% RH and 20°C. Due to the deposition of The values of contact angle measured at the NMM-1 resin into the cell wall (with cell wall phase boundary between wood and liquid bulking), the empty space of micro voids is standard provide an issue point for the study of believed to be smaller; the ability for thermodynamic properties of wood surface. adsorption of water vapor was lessened, and, The values of this angle are used to calculate as a consequence, the EMCR and RS were surface free energy and reflect wettability of reduced. wood surface (Jozep, 2014). Figure 8. Contact angle of the control, untreated and AKD, NMM treated veneer As can be seen in the Figure 8, contact after water drop was applied on veneer surface; angle of the untreated veneers reduced very and showed insignificant difference. Therefore, fast in the first 5 seconds, and then reduced wettability of AKD, NMM-1 and mNMM-2 slowly to about 35° after 17 seconds. Congtact treated veneers presented much lower than the angle of the control veneers was much higher untreated and control veneers. than that of untreated veneers because hot IV. CONCLUSIONS press curing made veneers become more Beech veneers were impregnated with 10% hydrophobic. Contact angle values of AKD, solid content of the AKD, NMM-1 and NMM-1 and mNMM-2 treated veneers were mNMM-2 chemicals. High water repellence almost consistant during the first 20 seconds of the treated veneers resulted from the closing JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 149 Forest Industry water paths in lumen or blocking micro voids formaldehyde resin to improve the hardness of Norway and/or hydroxyl groups of the cell wall as spruce wood. Journal of Applied Polymer Science, 93(4): 1900-1907. discussed in details. The cycle after each 8. Gindl, W., Müller, U. and Teischinger, A. (2003) submersion did not result in significant change Transverse compression strength and fracture of spruce of WREs in the second, third and fourth wood modified by melamine-formaldehyde submersion although weight loss of each impregnation of cell walls. Wood and Fiber Science, 35(2): 239-246. treatment increased from the first cycle to the 9. Hill, C.A.S. and Papadopoulos, A.N. (2001) A fourth submersion. Consequently, it can be review of methods used to determine the size of the cell stated that, the water repellence of the treated wall micro voids of wood. Journal Institute Wood veneers was stable after the wetting-drying Science, 90: 337-345. 10. Hill, C.A.S. (2002). How does the chemical cycles. modification of wood provide protection against decay Sorption behavior is related to the properties fungi? Presentation for Cost E22 - Finland. of modified cell wall, such as bulking and 11. Hill, C.A.S. (2006) Wood modification. covalent bonds/cross linking. The chemicals Chemical, thermal and other processes. John Wiley & Son, Ltd. such as NMM-1, mNMM-2 could react with 12. Hansmann, C., Deka, M., Wimmer, R. and Gindl, hydroxyl groups or deposit into the cell wall W. (2006) Artificial weathering of wood surfaces induced the reduction in EMCR and RS for the modified by melamine formaldehyde resins. Holz als treated veneers, while large AKD particles Roh-und Werkstoff, 64(3): 198-203 13. Hubbe, M.A. (2006) Paper's resistance to wetting could not penetrate and modify the cell wall - A review of internal sizing chemicals and their effects. therefore did not reduce EMCR and RS in Bioresources, 2(1): 106-145. humid environment for the treated veneers. 14. Hundhausen, U., Militz, H. and Mai, C. (2009) The values of contact angle which reflect Use of alkyl ketene dimer (AKD) for surface modification of particleboard chips. Holz als Roh-und wettability were in accordance with the water Werkstoff, 67(1): 37-45. repellence and equilibrium moisture content of 15. INEOS (2006) Madurit MW 840/75 WA, the treated veneer. Technical data sheet. REFERENCES 16. Inoue, M., Ogata, S., Nishikawa, M., Otsuka, Y., Kawai, S. and Norimoto, M. (1993) Dimensional 1. BASF (2003) Basoplast 4118 MC. Technical stability, mechanical-properties, and color changes of a information, TI/P 3399. low-molecular-weight melamine-formaldehyde resin 2. Borgin, K. (1965) The testing and evaluation of impregnated wood. Mokuzai Gakkaishi, 39(2): 181-189. water repellents. Record of Fifteenth Annual Convention 17. Jozef K. (2014), wetting of wood surface by a - B.W.P.A: 67-84. liquid of a different polarity, Wood reseach, 59 (1): 11-24. 3. Ciba (2002) Ciba phobotex VFN. Technical data 18. Lukowsky, D., Peek, R.D. and Rapp, A.O. sheet. (1997) Water-based silicones on wood. Proceedings of 4. Deka, M. and Saikia, C.N. (2000) Chemical the International Research Group on Wood Preservation, modification of wood with thermosetting resin: effect on Document No: IRG/WP 97-30144. dimensional stability and strength property. Bioresource 19. Lukowsky, D., Büschelberger, F. and Schmidt, Technology, 73(2): 179-181. O. (1999) In situ testing the influence of melamine 5. Donath, S. (2005) Treatment of wood with silanes. resins on the enzymatic activity of basidiomycetes, Ph.D Thesis, Wood Biology and Wood Technology Proceedings of the International Research Group on Institute, Georg - August University, Göttingen, Wood Preservation. Document No: IRG/WP 99-30194. Germany. 20. Pittman, C.U., Kim, M.G., Nicholas, D.D., 6. EN 321 (2002) Wood-based panels - Wang, L.C., Kabir, F.R.A., Schultz, T.P. and Ingram, Determination of moisture resistance under cyclic test L.L. (1994) Wood enhancement treatments 1. conditions. Impregnation of Southern yellow pine with melamine- 7. Gindl, W., Hansmann, C., Gierlinger, N., formaldehyde and melamine-ammeline-formaldehyde Schwanninger, M., Hinterstoisser, B. and Jeronimidis, resins. Journal of Wood Chemistry and Technology, G. (2004) Using a water-soluble melamine- 150 JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 Forest Industry 14(4): 577-603. Technical Association of the Pulp and Paper Industry, 21. Rapp, A.O. and Peek, R.D. (1996) Melamine Hensiki, Fapetoy. resins as preservatives - Results of biological testing. 28. Suttie, E.D., Hill, C.A.S., Jones, D. and Orsler, Proceedings of the International Research Group on R.J. (1998) Chemically modified solid wood - I. Wood Preservation, Document No: IRG/WP 96-40061. Resistance to fungal attack. Material und Organismen, 22. Rowell, R.M. and Banks, W.B. (1985) Water 32(3): 159-182. repellency and dimensional stability of wood. General 29. Troughto, G.E. and Chow, S.Z. (1968) Evidence Technical Report FPL-50, Forest Products Laboratory, for covalent bonding between melamine formaldehyde Department of Agriculture, Forest Service, U.S. glue and wood.Part I. Bond degradation. Journal of The 23. Rowell, R.M. (2005) Chemical modification: a Institute of Wood Science, 21: 29-33. non-toxic approach to wood preservation. Doniesienia- 30. Nguyen, H.M., Militz, H. and Mai, C. (2007) reports. DREWNO - WOOD 2005. Protection of wood for above ground application 24. Rapp, A.O. and Peek, R.D. (1999) through modification with a fatty acid modified N- Melaminharzimprägniertes sowie mit Wetterschutzlasur methylol/paraffin formulation. Proceedings of the oberflächenbehandeltes und unbehandeltes Vollholz International Research Group on Wood Preservation, während zweijähriger Freilandbewitterung. Holz als Document No: IRG/WP 07-40378. Roh- und Werkstoff, 57(5): 331-339. 31. Skaar, C. (1988). Wood-water relations. 25. Isogai, A. and Taniguchi, R. (1992) Sizing Springer-Verlag, Berlin. mechanism of alkylketene dimers. Part 2: Deterioration 32. Yulin Deng and Marcos Abazeri (1998), contact of AKD emulsion. Nordic Pulp & Paper Research, 4: angle measurement of wood fibers in surfactant and 205-211. polymer solutions, wood and fiber science, 30 (2). 26. Mai, C. and Militz, H. (2004) Modification of 33. Wepner, F., Krause, A. and Militz, H. (2007) wood with silicon compounds. Treatment systems based Weather resistance of N-methylol treated plywood on organic silicon compounds-a review. Wood Science panels, Proceedings of the 2nd International Symposium and Technology, 37(6): 453-461. on the Veneer Processing and Products, Vancouver, 27. Neimo, L. (1999) Papermaking chemistry. B.C, Canada, 305-314. TÍNH HÚT NƯỚC, HÚT ẨM VÀ THẤM ƯỚT BỀ MẶT CỦA VÁN MỎNG GỖ BEECH (Fagus sylvatica L.) BIẾN TÍNH VỚI CÁC HỢP CHẤT CÓ CHỨA N-METHYLOL MELAMINE VÀ ALKYL KETENE DIMER Trịnh Hiền Mai1, Nguyễn Minh Hùng2 1,2Trường Đại học Lâm nghiệp TÓM TẮT Kết quả xử lý ván mỏng gỗ Beech với các hóa chất từ công nghiệp giấy (alkyl ketene dimer, AKD), công nghiệp gỗ (N-methylol melamine, NMM-1) và công nghiệp dệt (fatty acid modified N-methylol melamine, mNMM-2) ở hàm lượng rắn 10% cho thấy khả năng chống hút nước trong giai đoạn đầu khá cao; Sau đó giảm đáng kể từ 4 giờ sau khi ngâm đến khi ván đạt trạng thái bão hòa nước. Khả năng chống hút nước ở trạng thái bão hòa nước thay đổi từ 5% (AKD) đến 19,3% (mNMM-2), do đó có một lượng hóa chất nhất định tích tụ trong ruột tế bào và vách tế bào của ván mỏng được xử lý với các hóa chất trên. Khả năng chống hút nước của ván mỏng được xử lý hóa chất ổn định qua các chu kỳ ngâm nước – sấy khô. Hóa chất NMM-1 và mNMM-2 có khả năng phản ứng với nhóm hydroxyl hoặc tích tụ trong vách tế bào làm giảm độ ẩm thăng bằng và tỷ lệ trương nở theo phương xuyên tâm của ván mỏng biến tính, trong khi đó các hạt AKD có kích thước lớn không thể di chuyển vào vách tế bào để biến tính do đó không làm giảm độ ẩm thăng bằng và tỷ lệ trương nở theo phương xuyên tâm. Khả năng thấm ướt của ván mỏng xử lý với AKD, NMM-1 và mNMM-2 thấp hơn nhiều so với ván mỏng đối chứng và ván không xử lý. Từ khoá: Độ ẩm thăng bằng, góc tiếp xúc, gỗ Beech, khả năng chống hút nước, tính thấm ướt, ván mỏng. Received : 14/9/2017 Revised : 02/10/2017 Accepted : 10/10/2017 JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 151

File đính kèm:

water_uptake_moisture_absorption_and_wettability_of_beech_ve.pdf

water_uptake_moisture_absorption_and_wettability_of_beech_ve.pdf