Effects of rosin sizing agent on the fixation of boron in Styrax tonkinensis wood

The aim of this study was to evaluate the effect of rosin sizing agent upon fixing boron in Styrax tonkinensis (Piere) wood treated with mixtures of 3% boric acid and 1% rosin sizing agent. After treatment, wood samples were also analyzed by scanning electron microscope observation and energy-Dispersive X-ray spectroscopy (SEM-EDX). The results showed that all boron-rosin formulations impregnated Styrax tonkinensis wood evenly penetrated into the wood blocks. Boron-rosin treatment decreased by 16% the amount of boron leaching from treated wood samples compared with those from the samples treated with boric acid alone. The SEM-EDX analysis proved that the boron element was still in the cell lumens of boron-rosin treated wood blocks after leaching. Results indicated that rosin emulsion sizing agent can have an effect on the fixation of boron in wood. This signifies that using of rosin as fixing agents may contribute to lead to wood treated with boron based preservatives being more widely used

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Tóm tắt nội dung tài liệu: Effects of rosin sizing agent on the fixation of boron in Styrax tonkinensis wood

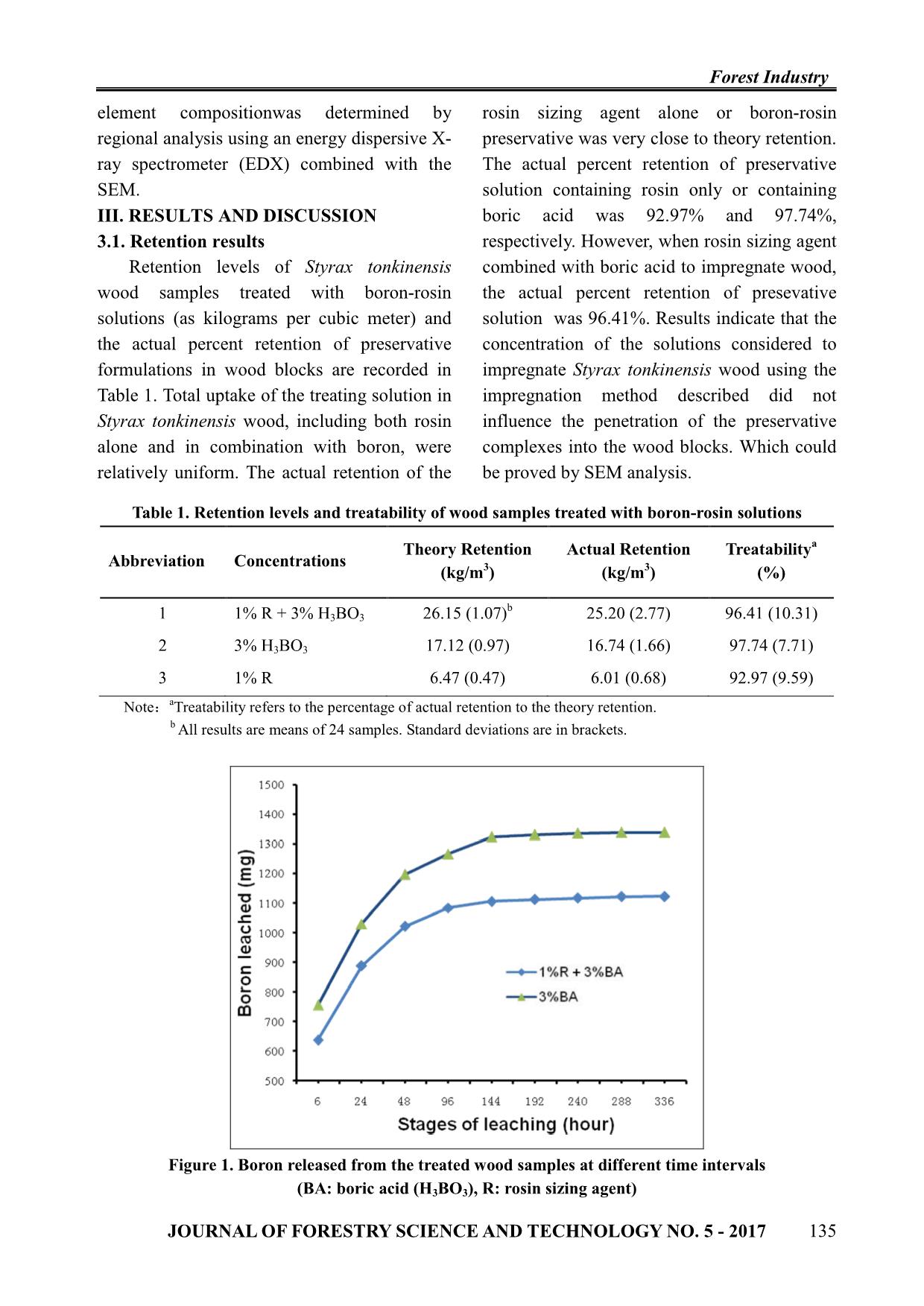

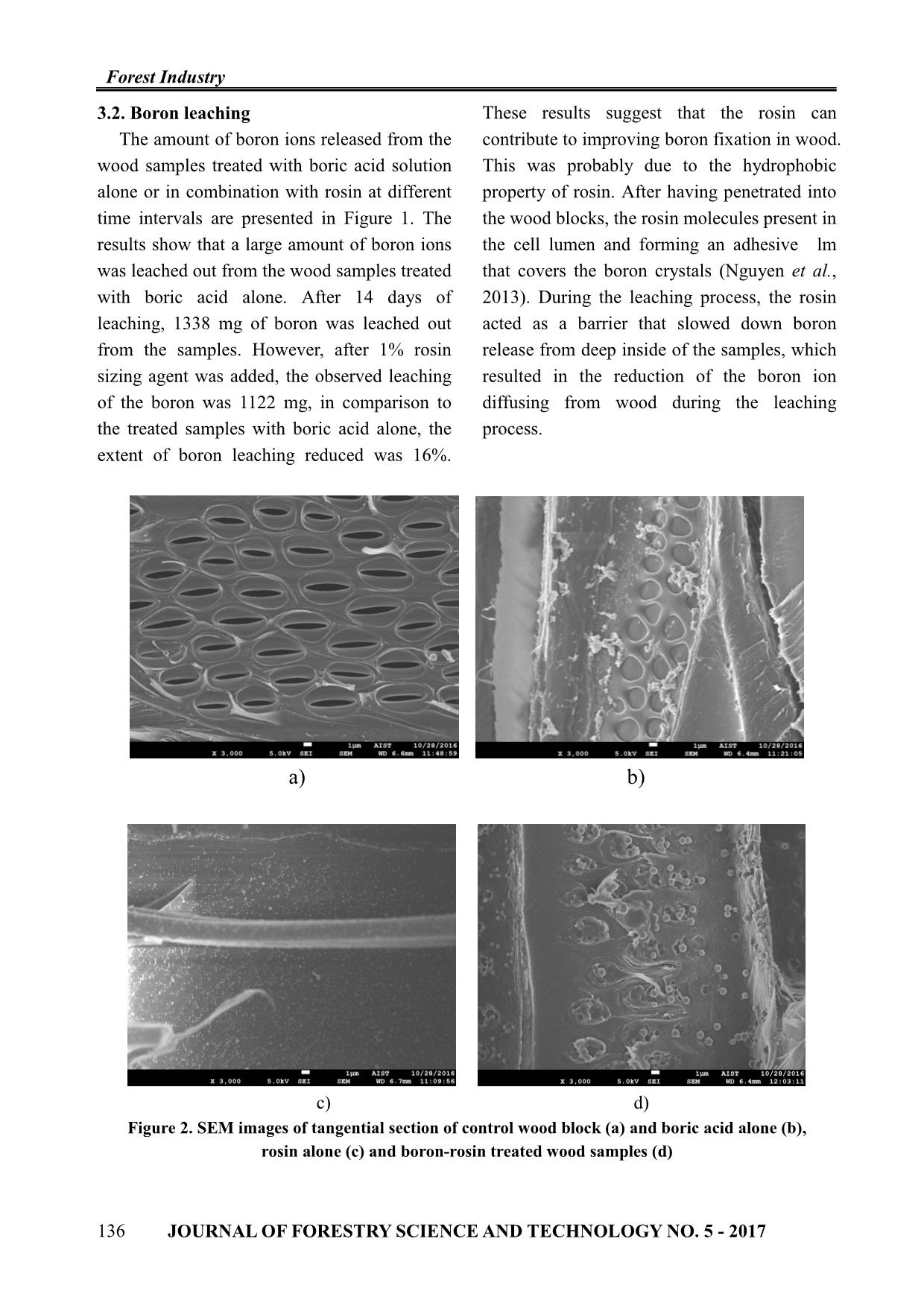

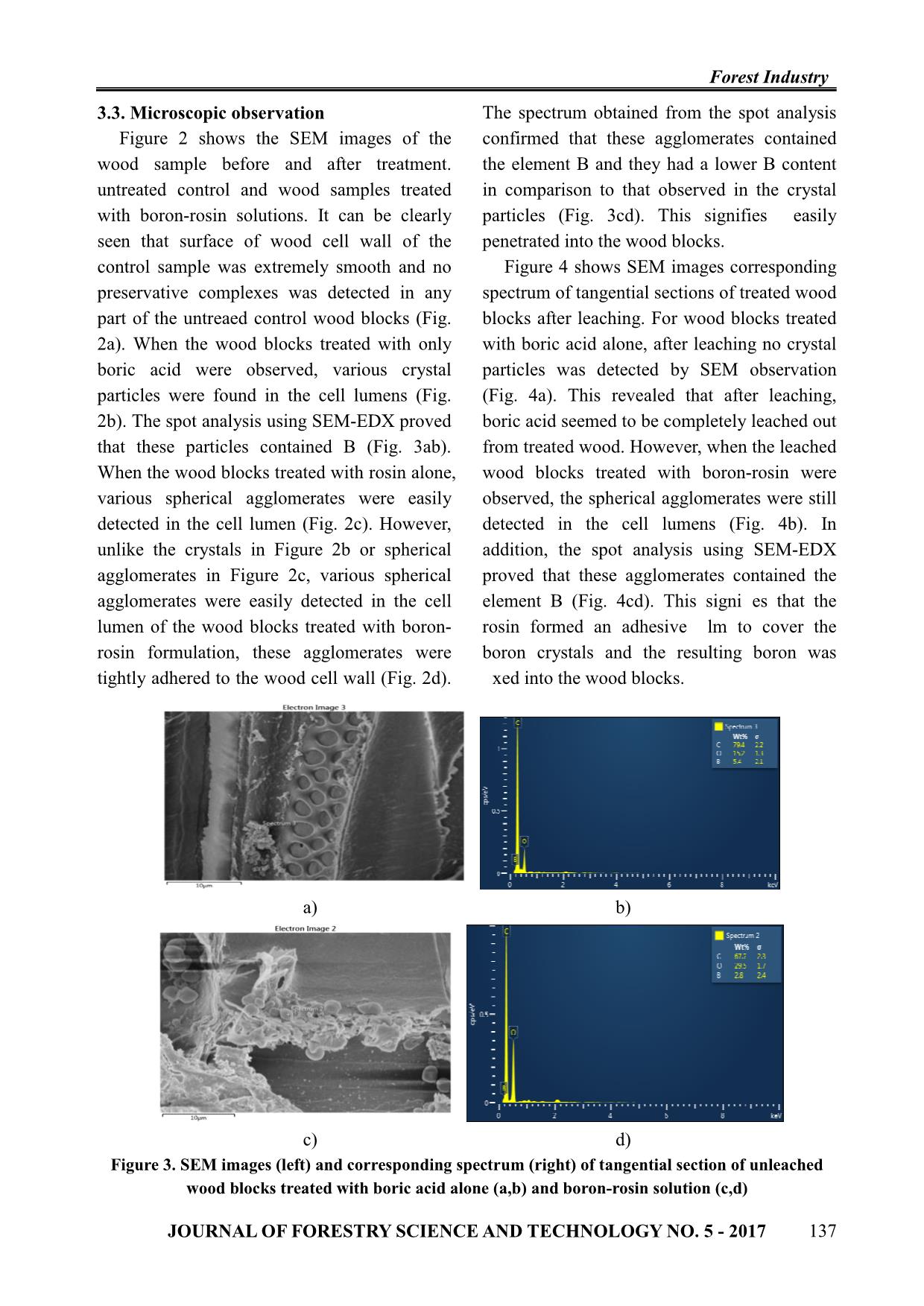

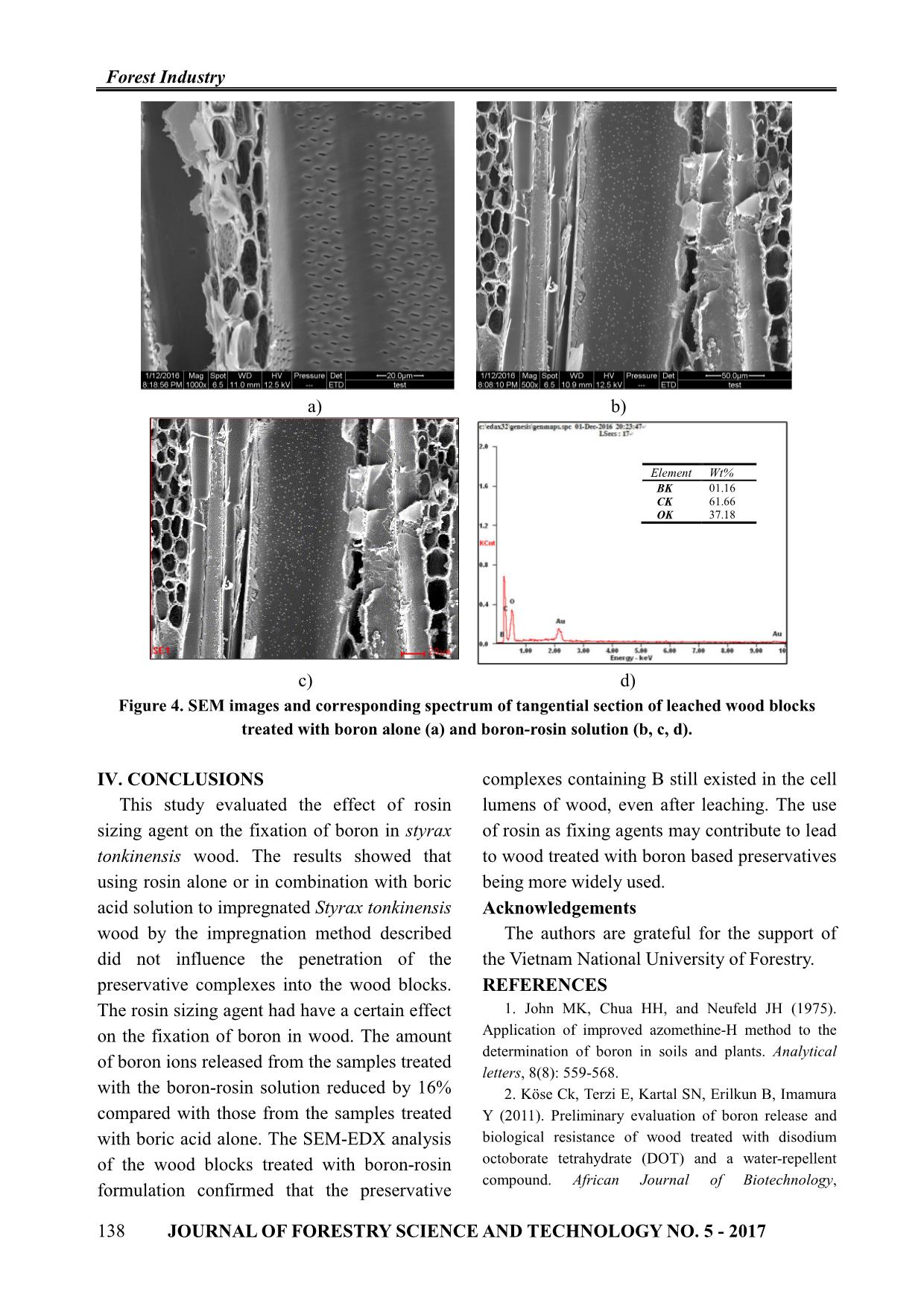

weight differences of the chosen blocks did not JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 133 Forest Industry exceed 0.5 g. retention of each block. And the percentage of The anionic rosin emulsion sizing agent (R) actual retention to the theory retention was was an industrial product and was supplied by regarded as the treatability of each preservative Guangxi Wuzhou Arakawa Chemical formulation. Industries Co., Ltd. In this study, it was used to 2.3. Leaching treated wood blocks impregnate into wood at the concentration of Leaching of boron was determined 1%. And 3% Boric acid (H3BO3) was provided according to the standard of the American by Tianjin Kermel Chemical Reagent Co., Ltd., Wood Preservers’ Association E11 (AWPA was used as a preservative salts. It was also E11 2007). Twelve blocks per treatment were combined with the rosin emulsion sizing agent air-dried, then immersed in beakers of distilled to impregnate wood. water over which a vacuum was applied for 30 2.2. Treating wood blocks min. Then the vacuum was released and the Before treatment, all sapwood blocks were wood blocks were immersed in the distilled oven-dried at 103oC overnight, weighed to the water. After 6 h, 24 h, 48 h, and 48-h intervals nearest 0.01 g and recorded as W1. The blocks the leaching water was removed and replaced were then vacuum-treated with the treatment with an equal amount of fresh distilled water. solution. The vacuum was applied for 30 min Leaching was carried out for a total of 14 days. at 0.1 MPa before supplying the solution into All leachates were collected and kept for boron the chamber. After the application another 30 analysis. min at 0.1 MPa vacuum diffusion period 2.4. Boron analysis followed. Then, the blocks were kept in the In order to measure the contents of boron treatment solution at ambient conditions until leached from the treated wood blocks, the complete saturation. The blocks were then leachates were analyzed by using the individually removed from the solution, wiped azomethine-H method described by John et al. lightly to remove solution from the wood (1975) and following American Wood surface, and immediately weighed to the Preservers’ Association standard method nearest 0.01 g to determine the mass after AWPA A2-07. impregnation (W2). The theory retention of 2.5. Microscopic observation each block was calculated using the following Small samples of dimensions 10 × 10 × 1 formula: mm were cut from the untreated control and GC the treated wood blocks, and located 3 mm Theory retention, kg/m 3 = 10 (1) V from each radial, tangential, and transverse Where G = W2-W1 is the weight in grams of surface of the wood block. Each sample was the treating solution absorbed by the block, C mounted on a metal stub with adhesive, and is the weight (g) of preservative in 100 grams then they were placed under vacuum and were of treating solution, and V is the volume of the sputter-coated with a thin layer (approximately block in cubic centimeters. 20 nm thick) of gold. The samples were then After calculating the retention, the treated observed with a scanning electron microscope samples were air-dried for 48 hours, and oven- (SEM, FEI Quanta 200, USA) at an dried at 103 °C overnight, and then weighed to accelerating voltage of 20 kV. Random determine the dry weights of the wood blocks observations were made on different structures after treatment. The difference between the dry to identify the existence of boron in the weights before and after treatment is the actual anatomical structure of the samples. The 134 JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 Forest Industry element compositionwas determined by rosin sizing agent alone or boron-rosin regional analysis using an energy dispersive X- preservative was very close to theory retention. ray spectrometer (EDX) combined with the The actual percent retention of preservative SEM. solution containing rosin only or containing III. RESULTS AND DISCUSSION boric acid was 92.97% and 97.74%, 3.1. Retention results respectively. However, when rosin sizing agent Retention levels of Styrax tonkinensis combined with boric acid to impregnate wood, wood samples treated with boron-rosin the actual percent retention of presevative solutions (as kilograms per cubic meter) and solution was 96.41%. Results indicate that the the actual percent retention of preservative concentration of the solutions considered to formulations in wood blocks are recorded in impregnate Styrax tonkinensis wood using the Table 1. Total uptake of the treating solution in impregnation method described did not Styrax tonkinensis wood, including both rosin influence the penetration of the preservative alone and in combination with boron, were complexes into the wood blocks. Which could relatively uniform. The actual retention of the be proved by SEM analysis. Table 1. Retention levels and treatability of wood samples treated with boron-rosin solutions Theory Retention Actual Retention Treatabilitya Abbreviation Concentrations (kg/m3) (kg/m3) (%) b 1 1% R + 3% H3BO3 26.15 (1.07) 25.20 (2.77) 96.41 (10.31) 2 3% H3BO3 17.12 (0.97) 16.74 (1.66) 97.74 (7.71) 3 1% R 6.47 (0.47) 6.01 (0.68) 92.97 (9.59) Note:aTreatability refers to the percentage of actual retention to the theory retention. b All results are means of 24 samples. Standard deviations are in brackets. Figure 1. Boron released from the treated wood samples at different time intervals (BA: boric acid (H3BO3), R: rosin sizing agent) JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 135 Forest Industry 3.2. Boron leaching These results suggest that the rosin can The amount of boron ions released from the contribute to improving boron fixation in wood. wood samples treated with boric acid solution This was probably due to the hydrophobic alone or in combination with rosin at different property of rosin. After having penetrated into time intervals are presented in Figure 1. The the wood blocks, the rosin molecules present in results show that a large amount of boron ions the cell lumen and forming an adhesive lm was leached out from the wood samples treated that covers the boron crystals (Nguyen et al., with boric acid alone. After 14 days of 2013). During the leaching process, the rosin leaching, 1338 mg of boron was leached out acted as a barrier that slowed down boron from the samples. However, after 1% rosin release from deep inside of the samples, which sizing agent was added, the observed leaching resulted in the reduction of the boron ion of the boron was 1122 mg, in comparison to diffusing from wood during the leaching the treated samples with boric acid alone, the process. extent of boron leaching reduced was 16%. a) b) c) d) Figure 2. SEM images of tangential section of control wood block (a) and boric acid alone (b), rosin alone (c) and boron-rosin treated wood samples (d) 136 JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 Forest Industry 3.3. Microscopic observation The spectrum obtained from the spot analysis Figure 2 shows the SEM images of the confirmed that these agglomerates contained wood sample before and after treatment. the element B and they had a lower B content untreated control and wood samples treated in comparison to that observed in the crystal with boron-rosin solutions. It can be clearly particles (Fig. 3cd). This signifies easily seen that surface of wood cell wall of the penetrated into the wood blocks. control sample was extremely smooth and no Figure 4 shows SEM images corresponding preservative complexes was detected in any spectrum of tangential sections of treated wood part of the untreaed control wood blocks (Fig. blocks after leaching. For wood blocks treated 2a). When the wood blocks treated with only with boric acid alone, after leaching no crystal boric acid were observed, various crystal particles was detected by SEM observation particles were found in the cell lumens (Fig. (Fig. 4a). This revealed that after leaching, 2b). The spot analysis using SEM-EDX proved boric acid seemed to be completely leached out that these particles contained B (Fig. 3ab). from treated wood. However, when the leached When the wood blocks treated with rosin alone, wood blocks treated with boron-rosin were various spherical agglomerates were easily observed, the spherical agglomerates were still detected in the cell lumen (Fig. 2c). However, detected in the cell lumens (Fig. 4b). In unlike the crystals in Figure 2b or spherical addition, the spot analysis using SEM-EDX agglomerates in Figure 2c, various spherical proved that these agglomerates contained the agglomerates were easily detected in the cell element B (Fig. 4cd). This signi es that the lumen of the wood blocks treated with boron- rosin formed an adhesive lm to cover the rosin formulation, these agglomerates were boron crystals and the resulting boron was tightly adhered to the wood cell wall (Fig. 2d). xed into the wood blocks. a) b) c) d) Figure 3. SEM images (left) and corresponding spectrum (right) of tangential section of unleached wood blocks treated with boric acid alone (a,b) and boron-rosin solution (c,d) JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 137 Forest Industry a) b) Element Wt% BK 01.16 CK 61.66 OK 37.18 c) d) Figure 4. SEM images and corresponding spectrum of tangential section of leached wood blocks treated with boron alone (a) and boron-rosin solution (b, c, d). IV. CONCLUSIONS complexes containing B still existed in the cell This study evaluated the effect of rosin lumens of wood, even after leaching. The use sizing agent on the fixation of boron in styrax of rosin as fixing agents may contribute to lead tonkinensis wood. The results showed that to wood treated with boron based preservatives using rosin alone or in combination with boric being more widely used. acid solution to impregnated Styrax tonkinensis Acknowledgements wood by the impregnation method described The authors are grateful for the support of did not influence the penetration of the the Vietnam National University of Forestry. preservative complexes into the wood blocks. REFERENCES The rosin sizing agent had have a certain effect 1. John MK, Chua HH, and Neufeld JH (1975). on the fixation of boron in wood. The amount Application of improved azomethine-H method to the determination of boron in soils and plants. Analytical of boron ions released from the samples treated letters, 8(8): 559-568. with the boron-rosin solution reduced by 16% 2. Köse Ck, Terzi E, Kartal SN, Erilkun B, Imamura compared with those from the samples treated Y (2011). Preliminary evaluation of boron release and with boric acid alone. The SEM-EDX analysis biological resistance of wood treated with disodium of the wood blocks treated with boron-rosin octoborate tetrahydrate (DOT) and a water-repellent compound. African Journal of Biotechnology, formulation confirmed that the preservative 138 JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 Forest Industry 10(10):1833-1839. Reducing leaching of boron-based wood preservatives - 3. Li S, Thanh-Hien N. T, Han S, and Li J (2011). a review of research. Bioresour Technol., 99(15):7312– Application of rosin in wood preservation Chemistry 7322. and Industry of Forest Products, 31(5), 117-121. 10. Sen S, Tascioglu C, Tırak K (2009). Fixation, 4. Li S, Wang X, and Li J (2009). Effect of two water leachability, and decay resistance of wood treated with borne rosin on wood protection. Transactions of China some commercial extracts and wood preservative salts. Pulp and Paper 24(supplement), 200-203. International Biodeterioration & Biodegradation, 5. Lesar B, Kralj P, Humar M (2009). Montan wax 63:135-41. improves performance of boron-based wood 11. Song ZQ (2002). Fine Chemical Applications of preservatives. Int Biodeterior Biodegrad, 63(3):306–310. Rosin (I)-Composition and properties of rosin. Journal 6 Lesar B, Budija F, Kralj P, Petriˇc M, Humar M of Chemical Industry of Forest Products, 36(4):29-33. (2012). Leaching of boron from wood impregnated with 12. Temiz A, Alfredsen G, Eikenes M, Terzıev N preservative solutions based on boric acid and lique ed (2008). Decay resistance of wood treated with boric acid wood. Eur. J. Wood Prod., 70:365-367. and tall oil derivates. Bioresource Technology, 99:2102- 7. Nguyen TTH, Li J, Li S (2012). Effects of water- 2106. borne rosin on the fixation and decay resistance of 13. Tomak ED, Hughes M, Yildiz UC, Viitanen H copper-based preservative treated wood. Bioresour, (2011). The combined effects of boron and oil heat 7(3):3573-84. treatment on beech and Scots pine wood properties. Part 8. Nguyen TTH, Li S, Li J, and Liang T (2013). 1: Boron leaching, thermogravimetric analysis, and Micro-distribution and fixation of a rosin-based chemical composition. J. Mater Sci., 46:598-607. micronized-copper preservative in poplar wood. 14. Yalinkilic MK (2000). PhD Thesis, Kyoto International Biodeterioration & Biodegradation, 83: University. 63-70. 15. Zhang G (2005). Progress of the studies on the 9. Obanda DN, Shupe TF, Barnes HM (2008). cationic rosin size. China Pulp and Paper, 24: 57-61. ẢNH HƯỞNG CỦA KEO NHỰA THÔNG ĐẾN KHẢ NĂNG CỐ ĐỊNH BORON TRONG GỖ BỒ ĐỀ Nguyễn Thị Thanh Hiền1, Li Shujun2 1Trường Đại học Lâm nghiệp 2Trường Đại học Lâm nghiệp Đông Bắc, Trung Quốc TÓM TẮT Mục đích của nghiên cứu này là đánh giá ảnh hưởng của keo nhựa thông đến khả năng rửa trôi của boron từ gỗ Bồ đề được xử lý bởi hỗn hợp của 3% axit boric và 1% keo nhựa thông. Các mẫu gỗ sau khi xử lý được quan sát và phân tích bằng một phổ kế tán sắc năng lượng tia X kết hợp với kính hiển vi điện tử (SEM-EDX). Kết quả cho thấy rằng tất cả các công thức boron - nhựa thông được ngâm tẩm vào gỗ Bồ đề đều thẩm thấu tốt vào các mẫu gỗ thí nghiệm. Gỗ được xử lý bởi công thức kết hợp boron-nhựa thông đã giảm 16% lượng boron bị rửa trôi so với khi chỉ sử dụng axit boric để xử lý. Kết quả phân tích SEM-EDX cũng đã chứng minh nguyên tố B vẫn tồn tại trong khoang tế bào của gỗ được xử lý bởi boron-nhựa thông sau khi rửa trôi. Kết quả đã cho thấy rằng dung dịch keo nhựa thông có một ảnh hưởng nhất định đến khả năng cố định boron trong gỗ. Điều này gợi ý rằng sử dụng nhựa thông để làm chất cố định có thể góp phần nâng cao khả năng sử dụng của gỗ được xử lý bởi các hợp chất chứa boron. Từ khóa: Boron, boron-nhựa thông, kháng rửa trôi, nhựa thông. Received : 22/3/2017 Revised : 27/4/2017 Accepted : 10/5/2017 JOURNAL OF FORESTRY SCIENCE AND TECHNOLOGY NO. 5 - 2017 139

File đính kèm:

effects_of_rosin_sizing_agent_on_the_fixation_of_boron_in_st.pdf

effects_of_rosin_sizing_agent_on_the_fixation_of_boron_in_st.pdf