Reactivity induced transient analysis when the occurrence of leakage in the dry irradiation channels of the Dalat Nuclear Research Reactor

The leakage from the reactor pool back into the dry irradiation channels due to corrosion or

mechanics based reason is a postulated event that could occur under operating conditions of the Dalat

nuclear research reactor (DNRR), especially the channel 7-1 which has been installed more than 30

years. When it occurs, the air space in these channels will be occupied by the water, subsequently a

water column will appear in fuel region. The appearance of water column considerably enhances

medium of neutron moderation for its surrounding fuel assemblies. As a result, a positive reactivity is

inserted in the core and this event is classified as an insertion of excess reactivity. This event needs to

be addressed by analysis and assessment from safety point of view and the results of analysis are also

important for updating the reactor operating procedures. This paper presents assumptions, computer

models and the results of analysis for such event in the DNRR by using MCNP5 code (code for

neutronics analysis) and EUREKA-2/RR code (code for transient analysis). The calculation results

include value of reactivity insertion, change in power of reactor, as well as surface temperature of the

hottest fuel assembly. This research contributes to updating the reactor operating procedure.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Tóm tắt nội dung tài liệu: Reactivity induced transient analysis when the occurrence of leakage in the dry irradiation channels of the Dalat Nuclear Research Reactor

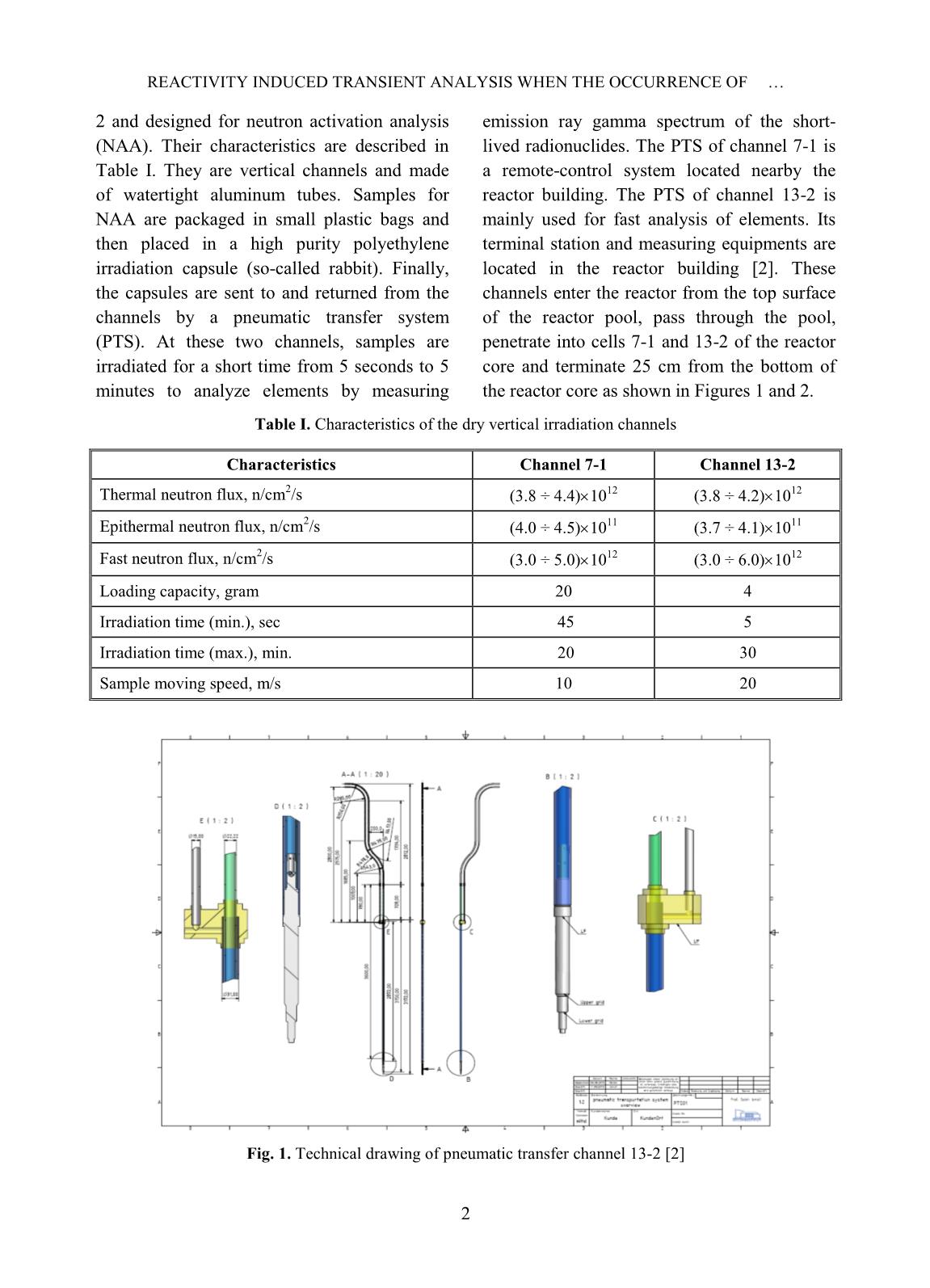

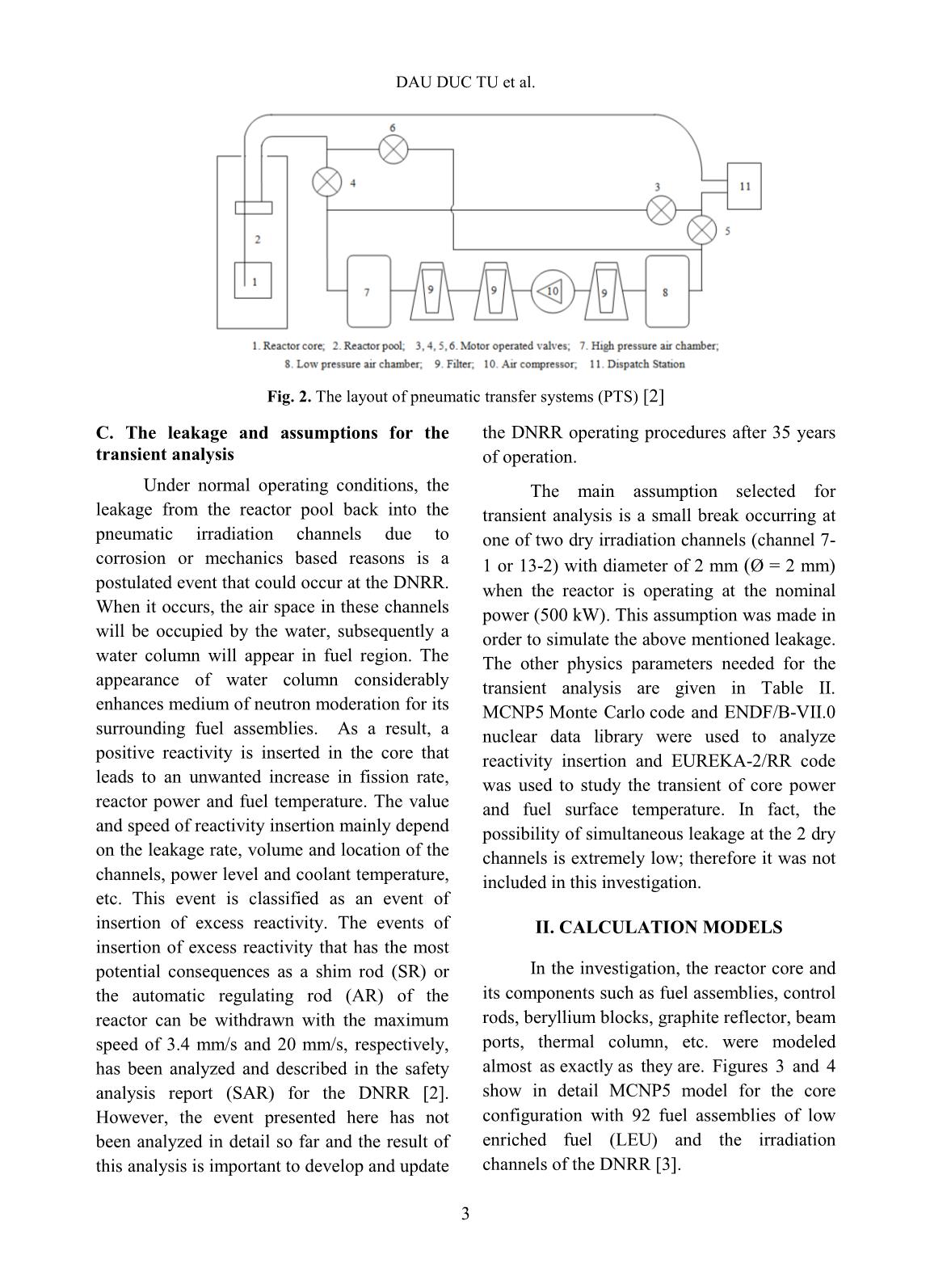

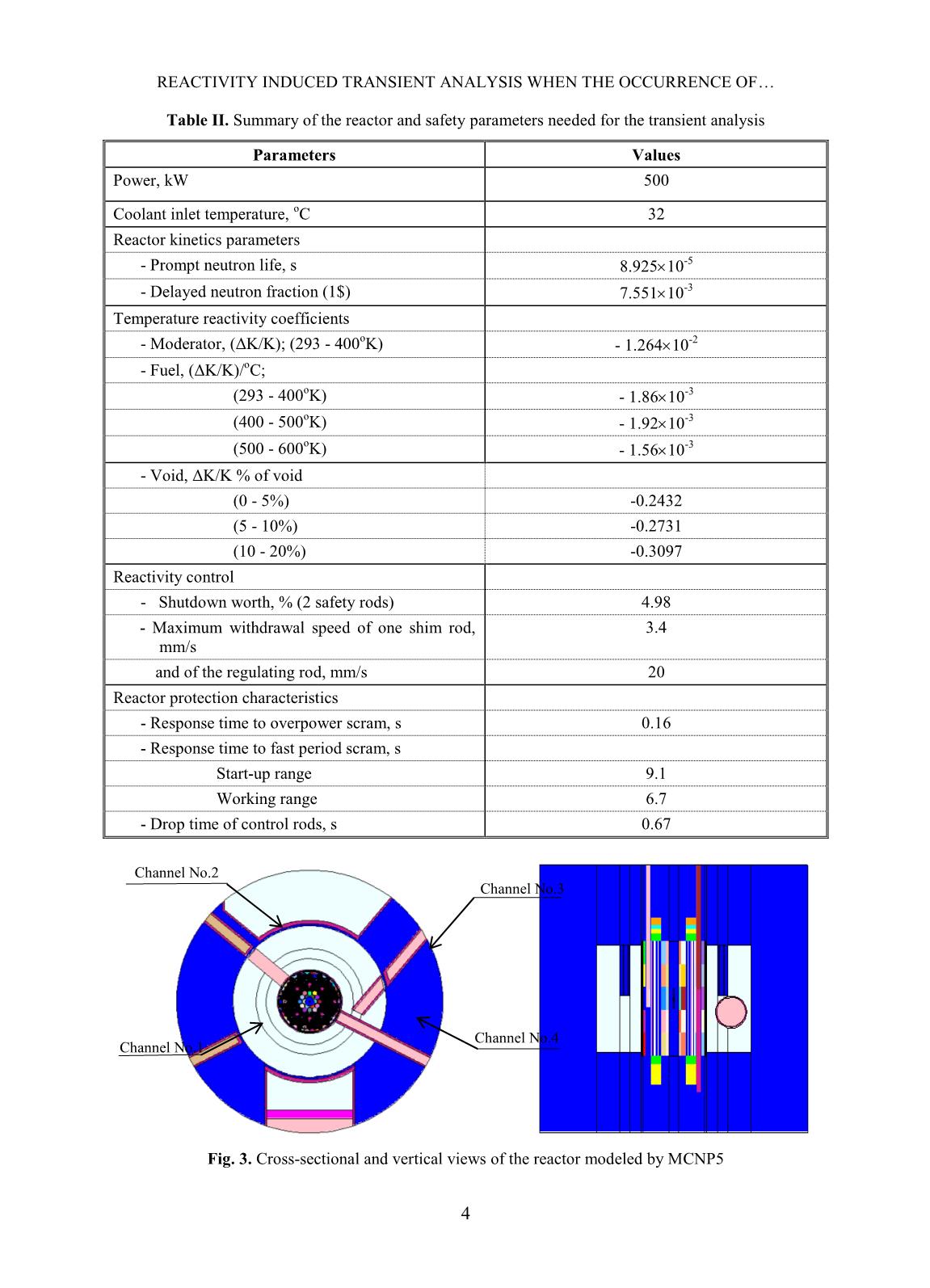

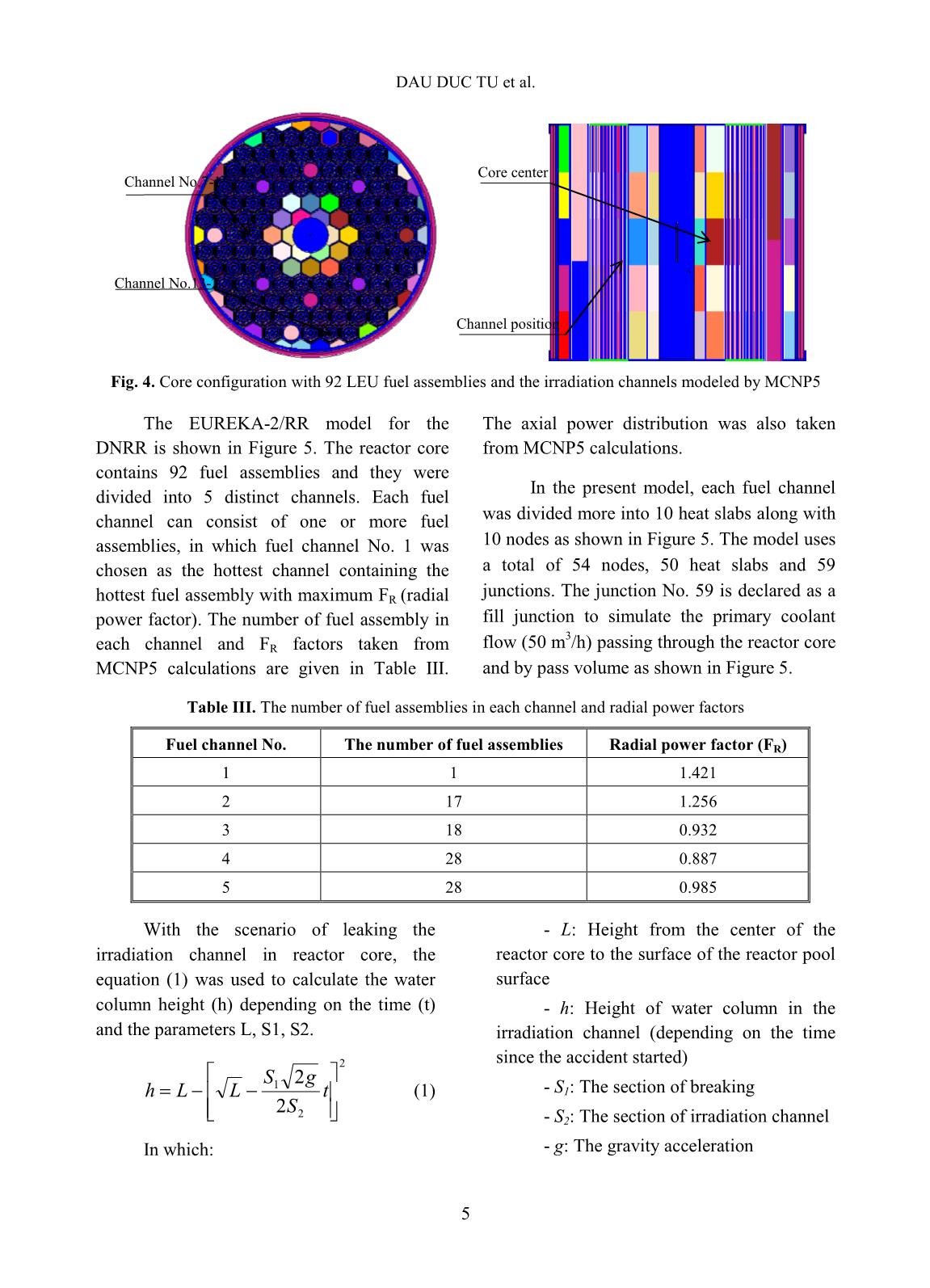

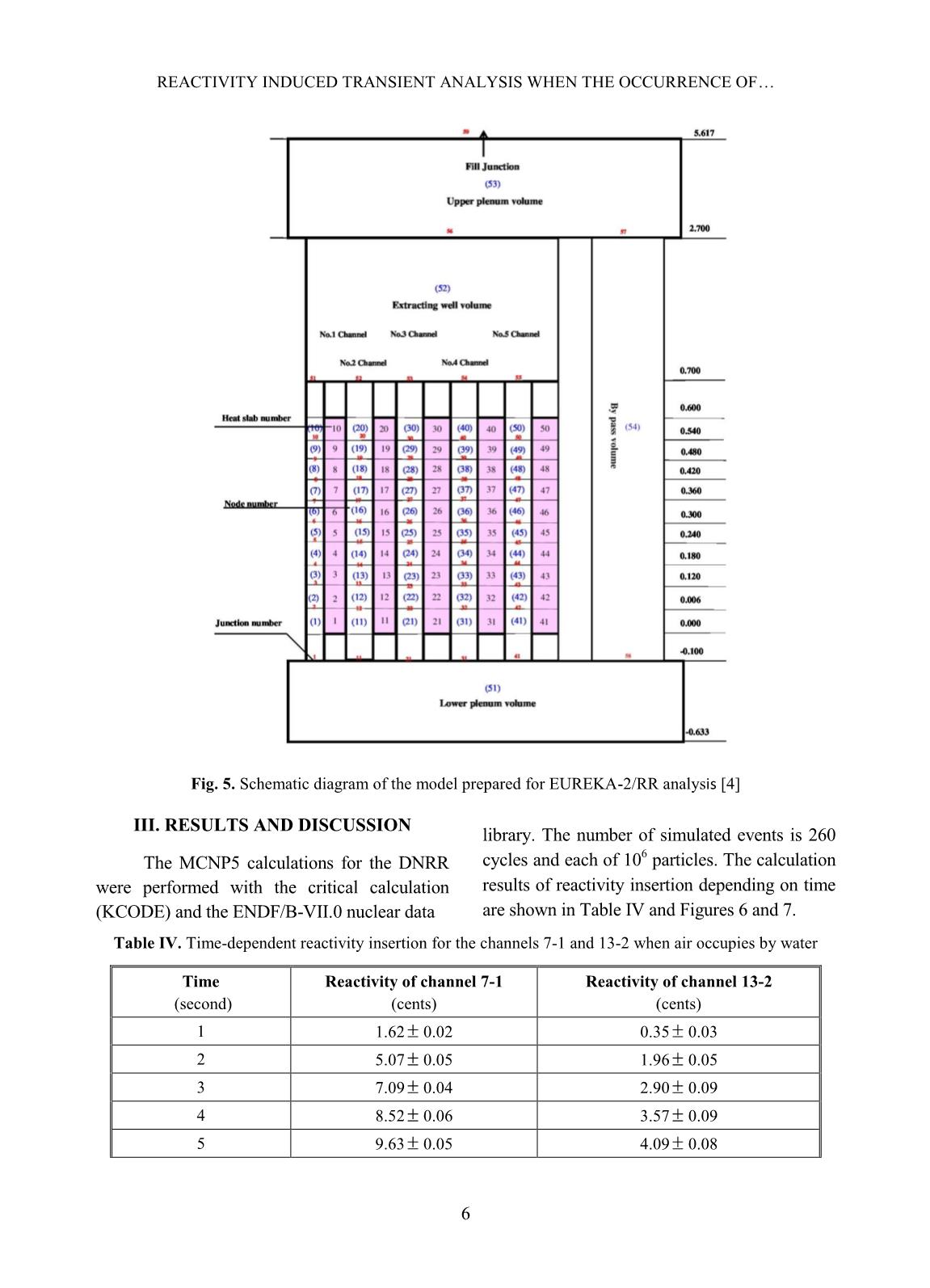

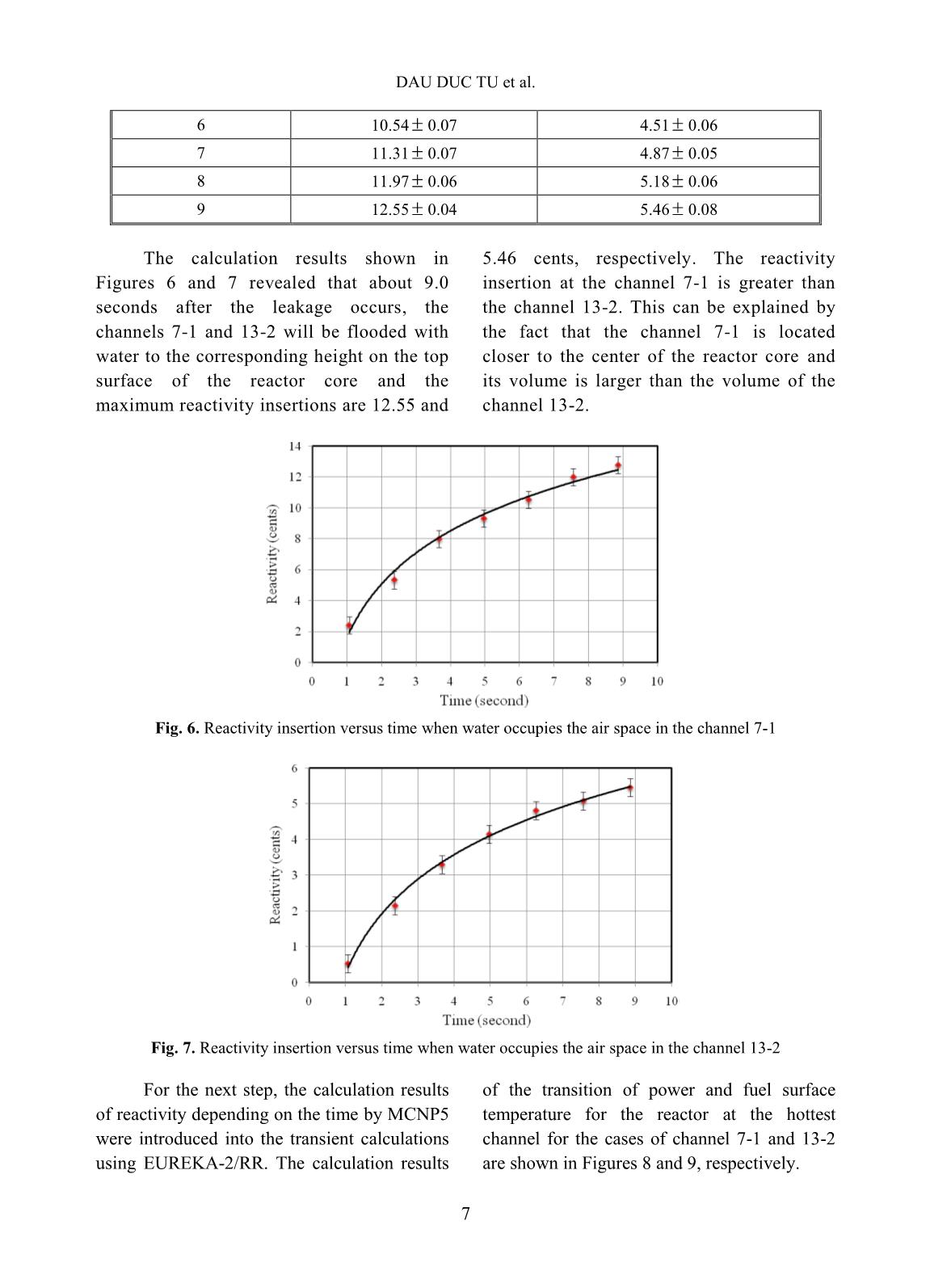

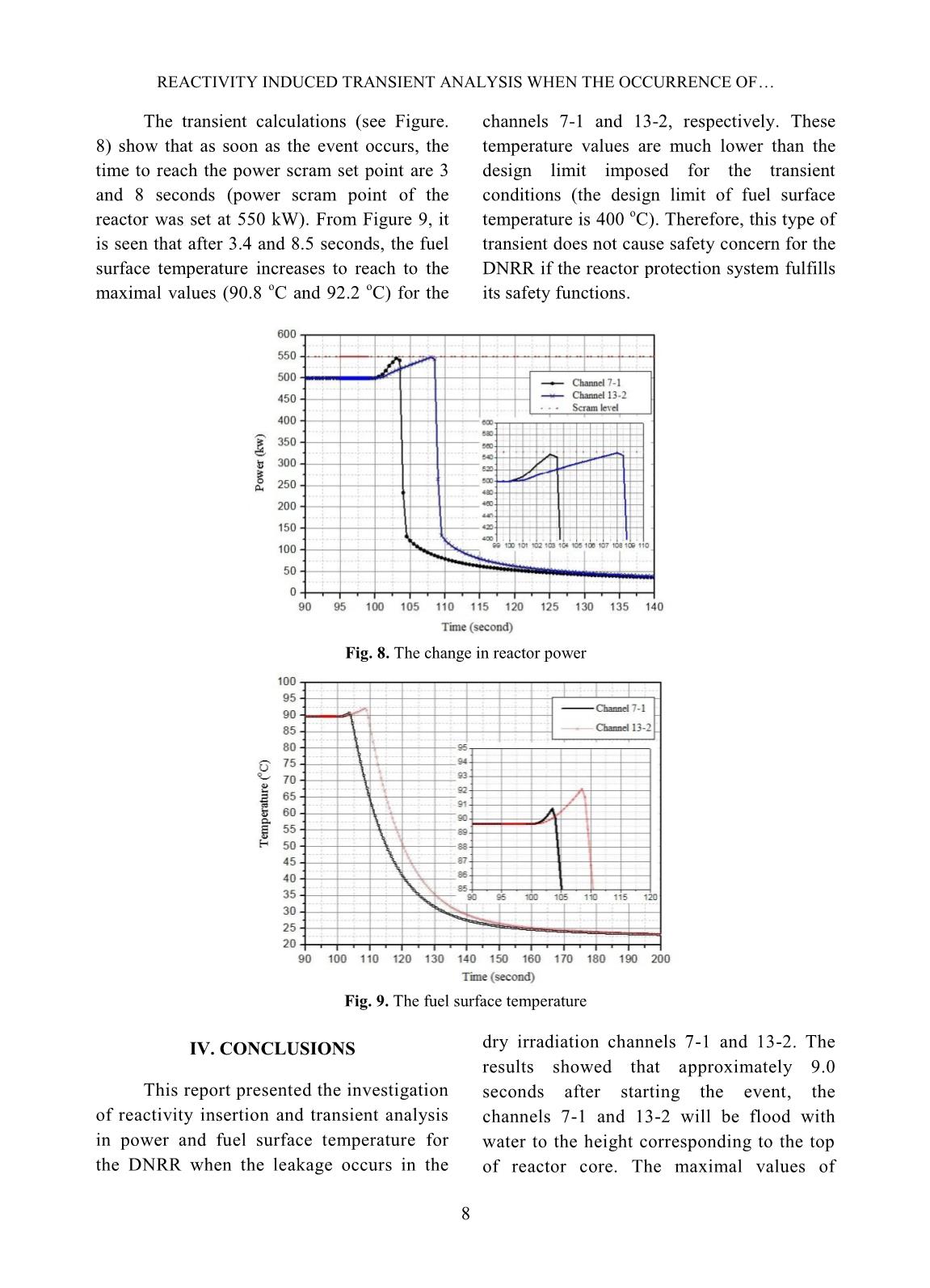

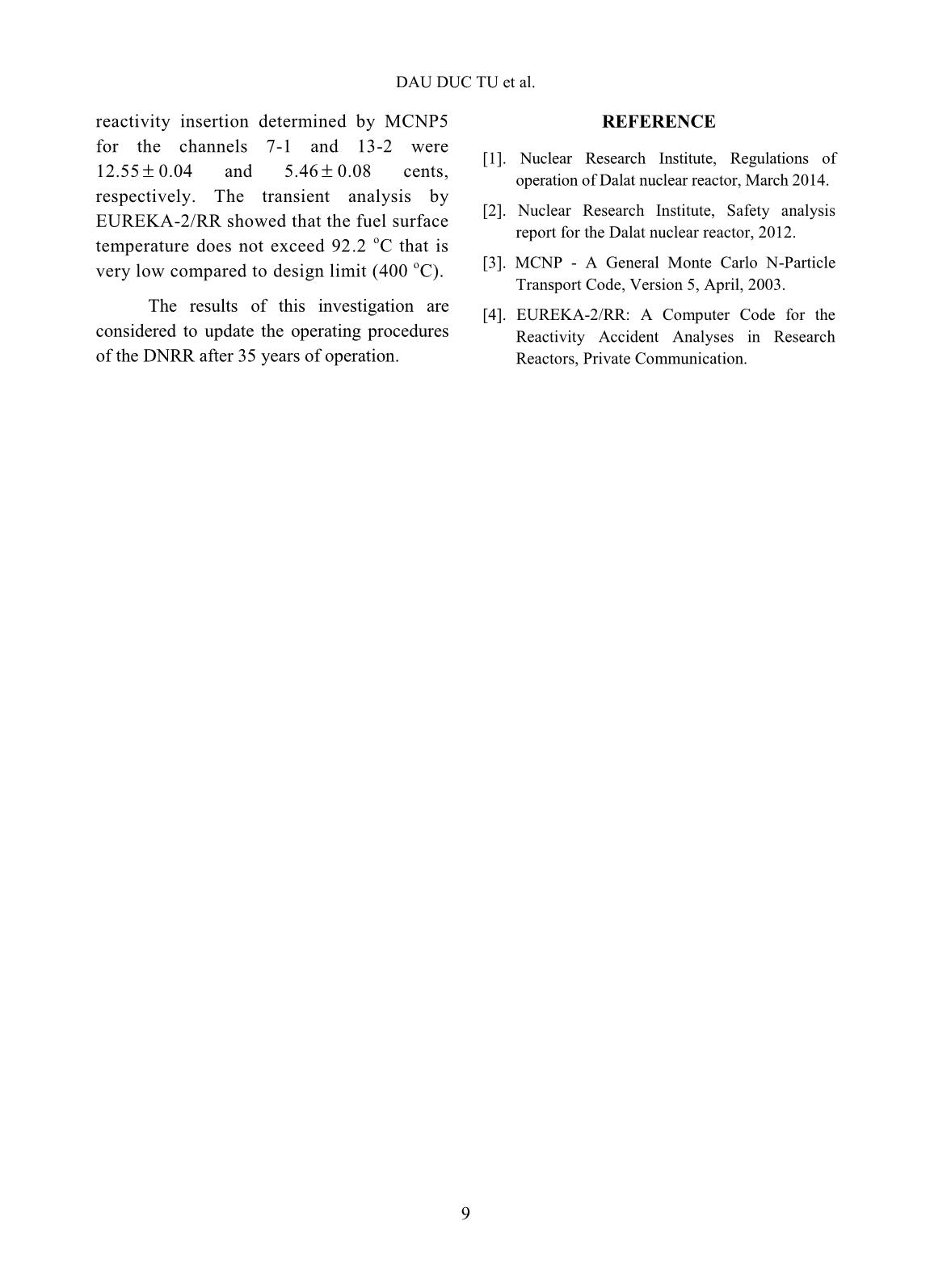

irradiation channels of the Dalat Nuclear Research Reactor Dau Duc Tu, Nguyen Minh Tuan, Le Vinh Vinh, Huynh Ton Nghiem, Nguyen Kien Cuong, Tran Quoc Duong, Bui Phuong Nam Reactor Center, Dalat Nuclear Research Institute, VINATOM 01 Nguyen Tu Luc Str., Dalat, Lamdong, Vietnam. E-mail: tudd.re@dnri.vn (Received 06 December 2018, accepted 28 December 2018) Abstract: The leakage from the reactor pool back into the dry irradiation channels due to corrosion or mechanics based reason is a postulated event that could occur under operating conditions of the Dalat nuclear research reactor (DNRR), especially the channel 7-1 which has been installed more than 30 years. When it occurs, the air space in these channels will be occupied by the water, subsequently a water column will appear in fuel region. The appearance of water column considerably enhances medium of neutron moderation for its surrounding fuel assemblies. As a result, a positive reactivity is inserted in the core and this event is classified as an insertion of excess reactivity. This event needs to be addressed by analysis and assessment from safety point of view and the results of analysis are also important for updating the reactor operating procedures. This paper presents assumptions, computer models and the results of analysis for such event in the DNRR by using MCNP5 code (code for neutronics analysis) and EUREKA-2/RR code (code for transient analysis). The calculation results include value of reactivity insertion, change in power of reactor, as well as surface temperature of the hottest fuel assembly. This research contributes to updating the reactor operating procedure. Keywords: Dalat nuclear research reactor (DNRR), MCNP5, EUREKA-2/RR, reactivity insertion, transient analysis. I. INTRODUCTION A. General information The Dalat reactor, which is a swimming pool type reactor and uses light water as moderator and coolant, has 500 kW thermal power and put into operation in March, 1984. It was reconstructed and upgraded from the USA made 250 kW TRIGA reactor. A number of structures from the original TRIGA reactor such as the aluminum tank with the surrounding concrete shield, four beam-ports, thermal column and the graphite reflector were remained. The reactor core is currently loaded 92 low enriched fuel (LEU) assemblies (19.75%), 3 irradiation channels (2 dry channels and 1 wet channel), 12 beryllium rods and a neutron trap [1]. The fuel assemblies are VVR-M2 tubular fuel assemblies designed and manufactured in Russia. Each fuel assembly consists of three coaxial annular tubes as well as a header and a tail. The outermost fuel element has a hexagonal shape of 32 mm in width across parallel sides and the other two inner ones have a circular shape of 22 mm and 11 mm in outer diameter, respectively. The beryllium rods of the reactor have a hexagonal shape of 32 mm in width across its parallel sides [1]. B. Description of dry irradiation channels In the reactor core, there are two dry irradiation channels located in cells 7-1 and 13- REACTIVITY INDUCED TRANSIENT ANALYSIS WHEN THE OCCURRENCE OF 2 2 and designed for neutron activation analysis (NAA). Their characteristics are described in Table I. They are vertical channels and made of watertight aluminum tubes. Samples for NAA are packaged in small plastic bags and then placed in a high purity polyethylene irradiation capsule (so-called rabbit). Finally, the capsules are sent to and returned from the channels by a pneumatic transfer system (PTS). At these two channels, samples are irradiated for a short time from 5 seconds to 5 minutes to analyze elements by measuring emission ray gamma spectrum of the short- lived radionuclides. The PTS of channel 7-1 is a remote-control system located nearby the reactor building. The PTS of channel 13-2 is mainly used for fast analysis of elements. Its terminal station and measuring equipments are located in the reactor building [2]. These channels enter the reactor from the top surface of the reactor pool, pass through the pool, penetrate into cells 7-1 and 13-2 of the reactor core and terminate 25 cm from the bottom of the reactor core as shown in Figures 1 and 2. Table I. Characteristics of the dry vertical irradiation channels Characteristics Channel 7-1 Channel 13-2 Thermal neutron flux, n/cm 2 /s (3.8 ÷ 4.4) 1012 (3.8 ÷ 4.2) 1012 Epithermal neutron flux, n/cm 2 /s (4.0 ÷ 4.5) 1011 (3.7 ÷ 4.1) 1011 Fast neutron flux, n/cm 2 /s (3.0 ÷ 5.0) 1012 (3.0 ÷ 6.0) 1012 Loading capacity, gram 20 4 Irradiation time (min.), sec 45 5 Irradiation time (max.), min. 20 30 Sample moving speed, m/s 10 20 Fig. 1. Technical drawing of pneumatic transfer channel 13-2 [2] DAU DUC TU et al. 3 Fig. 2. The layout of pneumatic transfer systems (PTS) [2] C. The leakage and assumptions for the transient analysis Under normal operating conditions, the leakage from the reactor pool back into the pneumatic irradiation channels due to corrosion or mechanics based reasons is a postulated event that could occur at the DNRR. When it occurs, the air space in these channels will be occupied by the water, subsequently a water column will appear in fuel region. The appearance of water column considerably enhances medium of neutron moderation for its surrounding fuel assemblies. As a result, a positive reactivity is inserted in the core that leads to an unwanted increase in fission rate, reactor power and fuel temperature. The value and speed of reactivity insertion mainly depend on the leakage rate, volume and location of the channels, power level and coolant temperature, etc. This event is classified as an event of insertion of excess reactivity. The events of insertion of excess reactivity that has the most potential consequences as a shim rod (SR) or the automatic regulating rod (AR) of the reactor can be withdrawn with the maximum speed of 3.4 mm/s and 20 mm/s, respectively, has been analyzed and described in the safety analysis report (SAR) for the DNRR [2]. However, the event presented here has not been analyzed in detail so far and the result of this analysis is important to develop and update the DNRR operating procedures after 35 years of operation. The main assumption selected for transient analysis is a small break occurring at one of two dry irradiation channels (channel 7- 1 or 13-2) with diameter of 2 mm (Ø = 2 mm) when the reactor is operating at the nominal power (500 kW). This assumption was made in order to simulate the above mentioned leakage. The other physics parameters needed for the transient analysis are given in Table II. MCNP5 Monte Carlo code and ENDF/B-VII.0 nuclear data library were used to analyze reactivity insertion and EUREKA-2/RR code was used to study the transient of core power and fuel surface temperature. In fact, the possibility of simultaneous leakage at the 2 dry channels is extremely low; therefore it was not included in this investigation. II. CALCULATION MODELS In the investigation, the reactor core and its components such as fuel assemblies, control rods, beryllium blocks, graphite reflector, beam ports, thermal column, etc. were modeled almost as exactly as they are. Figures 3 and 4 show in detail MCNP5 model for the core configuration with 92 fuel assemblies of low enriched fuel (LEU) and the irradiation channels of the DNRR [3]. REACTIVITY INDUCED TRANSIENT ANALYSIS WHEN THE OCCURRENCE OF 4 Table II. Summary of the reactor and safety parameters needed for the transient analysis Parameters Values Power, kW 500 Coolant inlet temperature, o C 32 Reactor kinetics parameters - Prompt neutron life, s 8.925 10-5 - Delayed neutron fraction (1$) 7.551 10-3 Temperature reactivity coefficients - Moderator, (ΔK/K); (293 - 400oK) - 1.264 10-2 - Fuel, (ΔK/K)/oC; (293 - 400 o K) - 1.86 10-3 (400 - 500 o K) - 1.92 10-3 (500 - 600 o K) - 1.56 10-3 - Void, ΔK/K % of void (0 - 5%) -0.2432 (5 - 10%) -0.2731 (10 - 20%) -0.3097 Reactivity control - Shutdown worth, % (2 safety rods) 4.98 - Maximum withdrawal speed of one shim rod, mm/s 3.4 and of the regulating rod, mm/s 20 Reactor protection characteristics - Response time to overpower scram, s 0.16 - Response time to fast period scram, s Start-up range 9.1 Working range 6.7 - Drop time of control rods, s 0.67 Fig. 3. Cross-sectional and vertical views of the reactor modeled by MCNP5 Channel No.2 Channel No.1 Channel No.3 Channel No.4 DAU DUC TU et al. 5 Fig. 4. Core configuration with 92 LEU fuel assemblies and the irradiation channels modeled by MCNP5 The EUREKA-2/RR model for the DNRR is shown in Figure 5. The reactor core contains 92 fuel assemblies and they were divided into 5 distinct channels. Each fuel channel can consist of one or more fuel assemblies, in which fuel channel No. 1 was chosen as the hottest channel containing the hottest fuel assembly with maximum FR (radial power factor). The number of fuel assembly in each channel and FR factors taken from MCNP5 calculations are given in Table III. The axial power distribution was also taken from MCNP5 calculations. In the present model, each fuel channel was divided more into 10 heat slabs along with 10 nodes as shown in Figure 5. The model uses a total of 54 nodes, 50 heat slabs and 59 junctions. The junction No. 59 is declared as a fill junction to simulate the primary coolant flow (50 m 3 /h) passing through the reactor core and by pass volume as shown in Figure 5. Table III. The number of fuel assemblies in each channel and radial power factors Fuel channel No. The number of fuel assemblies Radial power factor (FR) 1 1 1.421 2 17 1.256 3 18 0.932 4 28 0.887 5 28 0.985 With the scenario of leaking the irradiation channel in reactor core, the equation (1) was used to calculate the water column height (h) depending on the time (t) and the parameters L, S1, S2. 2 2 1 2 2 t S gS LLh (1) In which: - L: Height from the center of the reactor core to the surface of the reactor pool surface - h: Height of water column in the irradiation channel (depending on the time since the accident started) - S1: The section of breaking - S2: The section of irradiation channel - g: The gravity acceleration Channel No.7-1 Channel No.13-2 Channel position Core center REACTIVITY INDUCED TRANSIENT ANALYSIS WHEN THE OCCURRENCE OF 6 Fig. 5. Schematic diagram of the model prepared for EUREKA-2/RR analysis [4] III. RESULTS AND DISCUSSION The MCNP5 calculations for the DNRR were performed with the critical calculation (KCODE) and the ENDF/B-VII.0 nuclear data library. The number of simulated events is 260 cycles and each of 10 6 particles. The calculation results of reactivity insertion depending on time are shown in Table IV and Figures 6 and 7. Table IV. Time-dependent reactivity insertion for the channels 7-1 and 13-2 when air occupies by water Time (second) Reactivity of channel 7-1 (cents) Reactivity of channel 13-2 (cents) 1 1.62 0.02 0.35 0.03 2 5.07 0.05 1.96 0.05 3 7.09 0.04 2.90 0.09 4 8.52 0.06 3.57 0.09 5 9.63 0.05 4.09 0.08 DAU DUC TU et al. 7 6 10.54 0.07 4.51 0.06 7 11.31 0.07 4.87 0.05 8 11.97 0.06 5.18 0.06 9 12.55 0.04 5.46 0.08 The calculation results shown in Figures 6 and 7 revealed that about 9.0 seconds after the leakage occurs, the channels 7-1 and 13-2 will be flooded with water to the corresponding height on the top surface of the reactor core and the maximum reactivity insertions are 12.55 and 5.46 cents, respectively. The reactivity insertion at the channel 7-1 is greater than the channel 13-2. This can be explained by the fact that the channel 7-1 is located closer to the center of the reactor core and its volume is larger than the volume of the channel 13-2. Fig. 6. Reactivity insertion versus time when water occupies the air space in the channel 7-1 Fig. 7. Reactivity insertion versus time when water occupies the air space in the channel 13-2 For the next step, the calculation results of reactivity depending on the time by MCNP5 were introduced into the transient calculations using EUREKA-2/RR. The calculation results of the transition of power and fuel surface temperature for the reactor at the hottest channel for the cases of channel 7-1 and 13-2 are shown in Figures 8 and 9, respectively. REACTIVITY INDUCED TRANSIENT ANALYSIS WHEN THE OCCURRENCE OF 8 The transient calculations (see Figure. 8) show that as soon as the event occurs, the time to reach the power scram set point are 3 and 8 seconds (power scram point of the reactor was set at 550 kW). From Figure 9, it is seen that after 3.4 and 8.5 seconds, the fuel surface temperature increases to reach to the maximal values (90.8 o C and 92.2 o C) for the channels 7-1 and 13-2, respectively. These temperature values are much lower than the design limit imposed for the transient conditions (the design limit of fuel surface temperature is 400 o C). Therefore, this type of transient does not cause safety concern for the DNRR if the reactor protection system fulfills its safety functions. Fig. 8. The change in reactor power Fig. 9. The fuel surface temperature IV. CONCLUSIONS This report presented the investigation of reactivity insertion and transient analysis in power and fuel surface temperature for the DNRR when the leakage occurs in the dry irradiation channels 7-1 and 13-2. The results showed that approximately 9.0 seconds after starting the event, the channels 7-1 and 13-2 will be flood with water to the height corresponding to the top of reactor core. The maximal values of DAU DUC TU et al. 9 reactivity insertion determined by MCNP5 for the channels 7-1 and 13-2 were 12.55 0.04 and 5.46 0.08 cents, respectively. The transient analysis by EUREKA-2/RR showed that the fuel surface temperature does not exceed 92.2 o C that is very low compared to design limit (400 o C). The results of this investigation are considered to update the operating procedures of the DNRR after 35 years of operation. REFERENCE [1]. Nuclear Research Institute, Regulations of operation of Dalat nuclear reactor, March 2014. [2]. Nuclear Research Institute, Safety analysis report for the Dalat nuclear reactor, 2012. [3]. MCNP - A General Monte Carlo N-Particle Transport Code, Version 5, April, 2003. [4]. EUREKA-2/RR: A Computer Code for the Reactivity Accident Analyses in Research Reactors, Private Communication.

File đính kèm:

reactivity_induced_transient_analysis_when_the_occurrence_of.pdf

reactivity_induced_transient_analysis_when_the_occurrence_of.pdf