Thiết kế bộ điều khiển mạng neural thích nghi bền vững cho tay máy robot phá băng

Trong nghiên cứu này, một sự kết hợp của kỹ thuật backstepping, wavelet mờ lặp lại kép dựa trên

mạng neural (RFWBONNs), bộ điều khiển chế độ trượt thích nghi (ASMC) và bộ điều khiển tích phân

tỉ lệ thích nghi (API) với ma sát vùng chết được đề xuất cho tay máy robot (IRM). Kết quả mô phỏng

cho thấy hiệu suất cao của phương pháp điều khiển này khi so sánh với bộ điều khiển mờ thích nghi

(AF) và đạo hàm tích phân tỉ lệ (PID). Với việc sử dụng cấu trúc RFWBONNs, bộ điều khiển được đề

xuất không chỉ thể hiện tính linh hoạt trong quá trình điều chỉnh tham số mà còn thể hiện khả năng bù

cho sai số xấp xỉ. Do đó, kết luận bộ điều khiển được đề xuất là phù hợp với điều khiển mạng neural

bền vững thích nghi (ARNNs) và có thể được sử dụng như là bổ sung và thay thế cho bộ điều khiển

backstepping truyền thống.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Tóm tắt nội dung tài liệu: Thiết kế bộ điều khiển mạng neural thích nghi bền vững cho tay máy robot phá băng

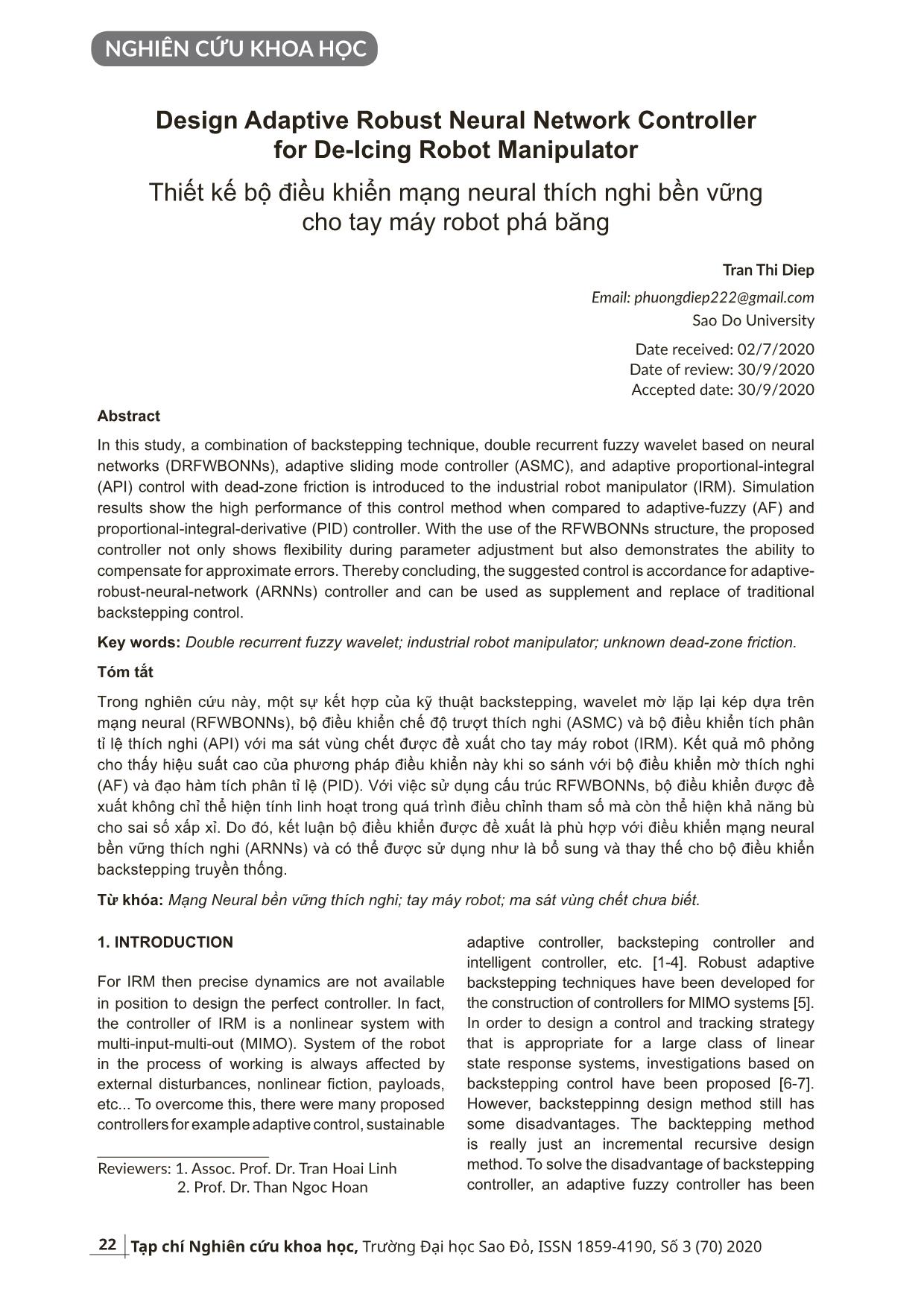

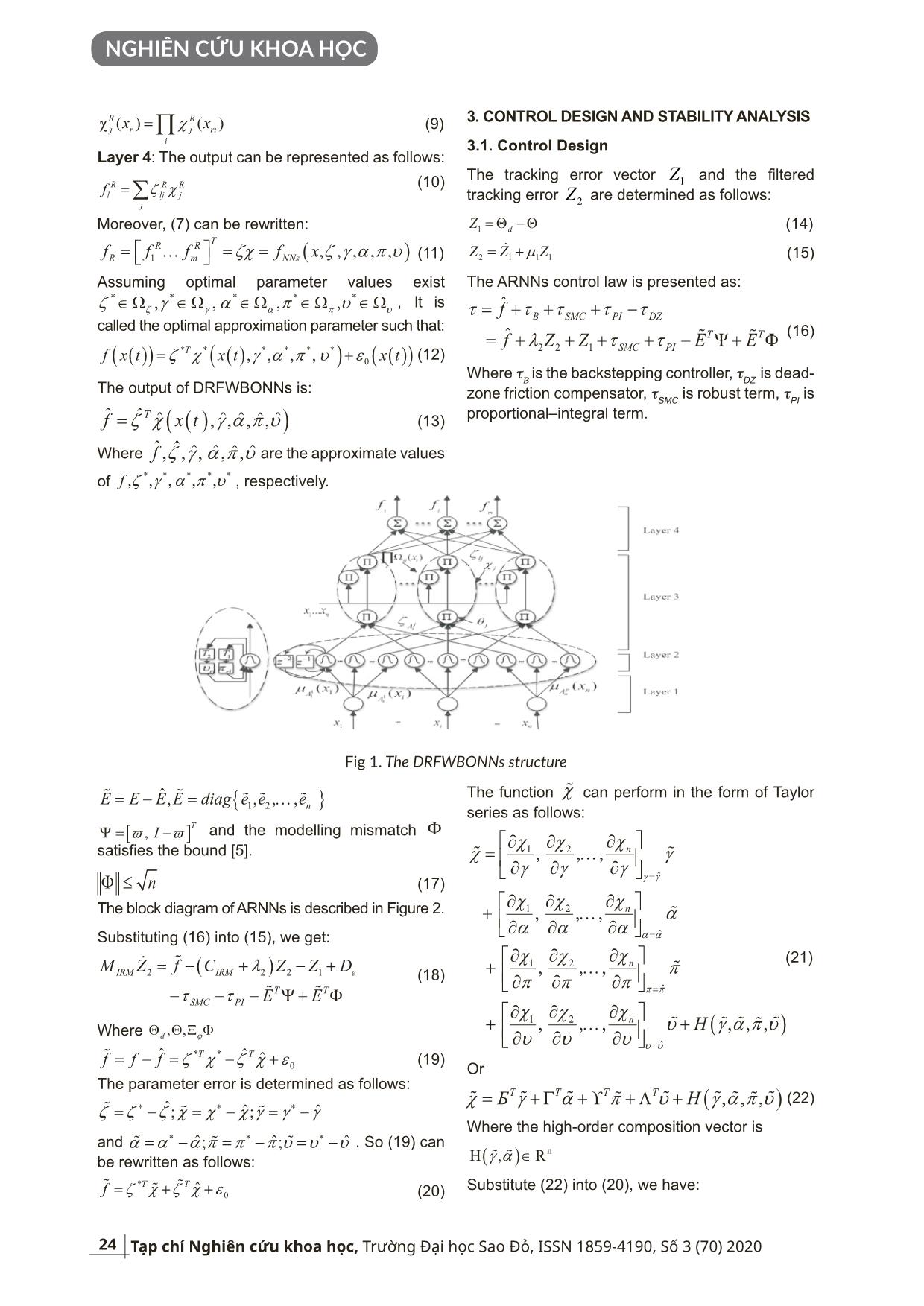

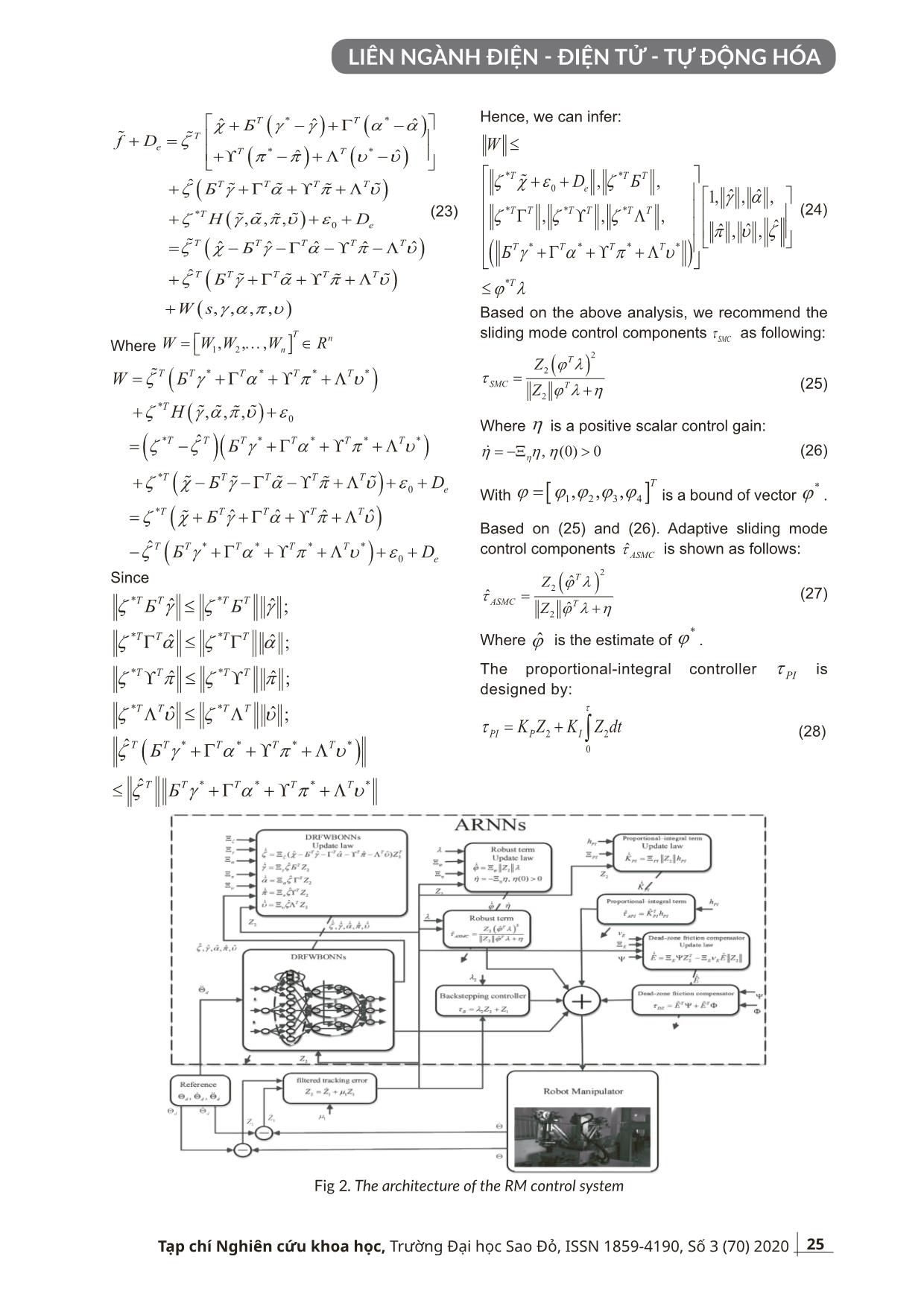

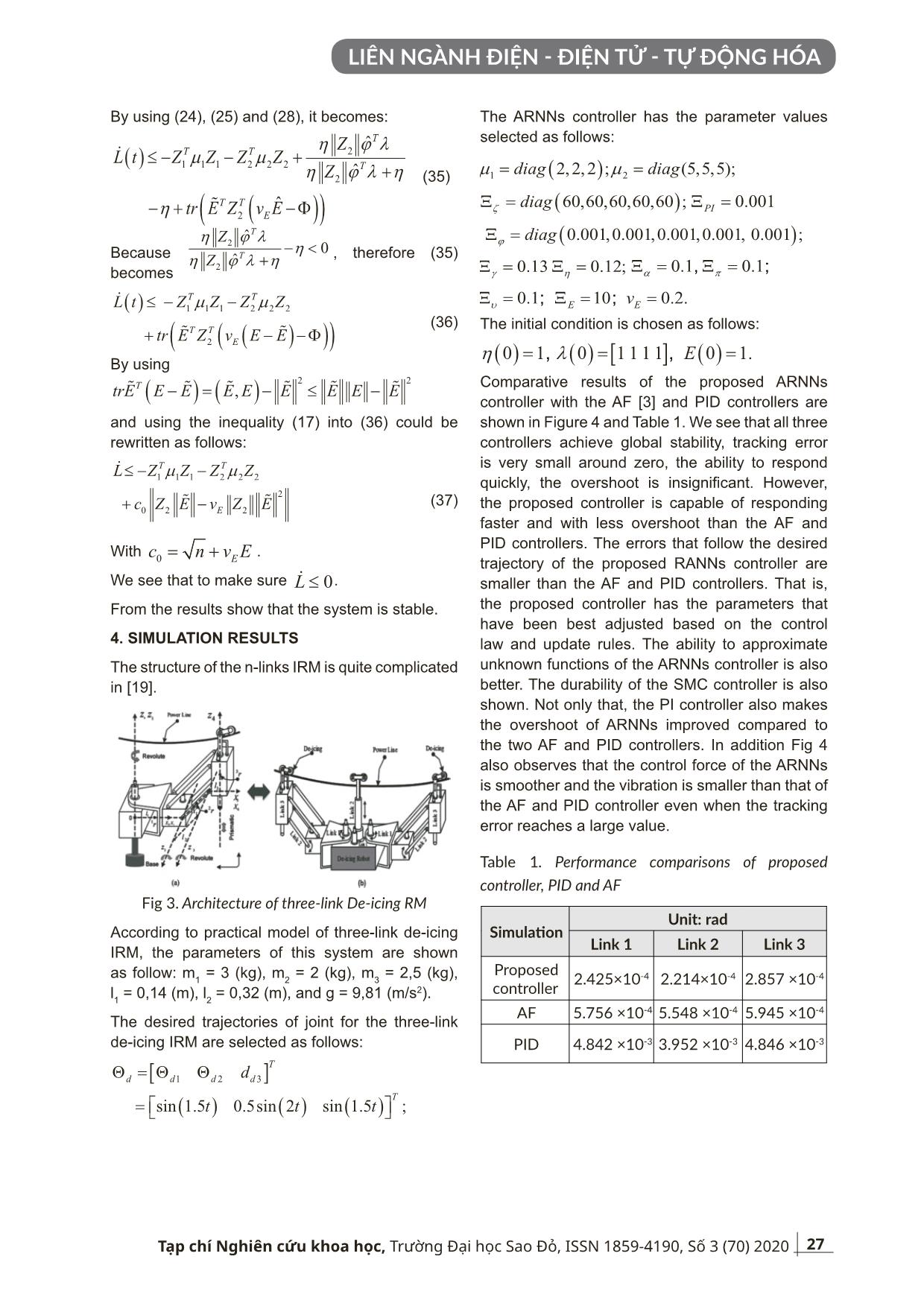

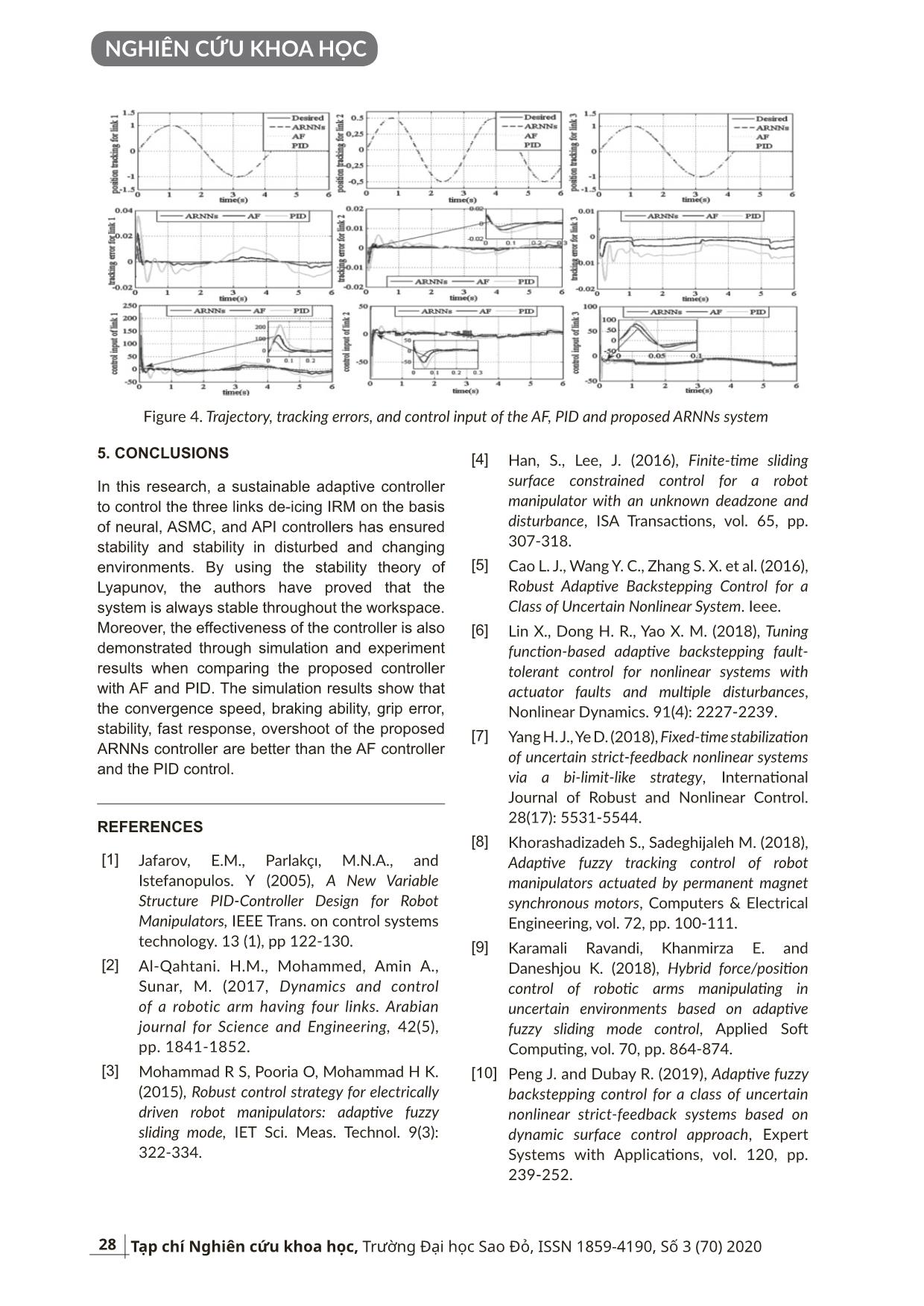

rewritten as follows: * 0ˆT Tf z c z ec= + +! !! (20) The function c! can perform in the form of Taylor series as follows: 1 2 ˆ 1 2 ˆ , , , , , , n n g g a a g a cc cc g g g cc c a a a = = é ¶ ù¶ ¶ = ê ú¶ ¶ ¶ë û ¶¶ ¶é ù + ê ú¶ ¶ ¶ë û ! ! ! ( ) 1 2 ˆ 1 2 ˆ , , , , , , , , , n n H p p u u cc c p p p cc c g a p uu u p uu = = ¶¶ ¶é ù + ê ú¶ ¶ ¶ë û ¶¶ ¶é ù + +ê ú¶ ¶ ¶ë û ! ! ! ! !! (21) Or ( ), , ,T T T TБ Hc g a p ug a p u= +G + ¡ +L +! ! ! !! ! ! !! (22) Where the high-order composition vector is ( ) nH , Rg a Î! ! Substitute (22) into (20), we have: 25 LIÊN NGÀNH ĐIỆN - ĐIỆN TỬ - TỰ ĐỘNG HÓA Tạp chí Nghiên cứu khoa học, Trường Đại học Sao Đỏ, ISSN 1859-4190, Số 3 (70) 2020 ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) ( ) * * * * * 0 ˆ ˆ ˆ ˆˆ ˆ ˆ ˆ ˆ , , , ˆ ˆ , , ˆ , , T T T e T T T T T T T e T T T T T T T T T T Бf D Б H D Б Б W s c g g a az p p u u z g z g a p u e z c z g a p u a p u g a p u g a p u é ù L - + - +G - + = +¡ - +L - + +G ¡ +L + + + - -G ¡ -L + ê úê úë û + = ++G ¡ + + ! ! ! !! ! ! ! ! ! ! ! ! !! Where ]1 2, , , T nnW W W W Ré= Îë ( ) ( ) ( )( ) ( ) ( ) ( ) * * * * 0 * * * * * * * * * 0 * * 0 * , , ˆ ˆ ˆ ˆ ˆ ˆ , T T T T T T T T T T T T T T T T T e T T T T T T T T T T e W Б H Б Б D Б Б D z g a z g a p u e z z g a z c e z c p u p u g a p u g a p u g a p uz e = +G ¡ +L + + = - +G ¡ +L + - -G ¡ +L + + = + +G ¡ +L - +G ¡ +L + + + + - + + ! ! ! ! !! !! ! ! ! Since * * * * * * * * ˆ ; ˆ ; ˆ ; ˆ ; ˆ ˆ ˆ ˆ T T T T T T T T T T T T T T T T Б Бz u z g z z a z a z p z z u g p £ G £ G ¡ £ ¡ L £ L ( )* * * * * * * * ˆ ˆ T T T T T T T T T T Б Б z g a z g a p u p u +G ¡ +L £ ¡++ +L + G Hence, we can infer: ( )* * * 0 * * * * * * * , , ˆ ˆ1, , , , , , ˆˆˆ , , T T T e T T T T T T T T T T T W D Б Б z e z g a z z z p u z c g a p u lj £ + + é ùê úG ¡ L ê úë û +G ú¡ + é ùê úê úê úê +ë ûL £ ! (24) Based on the above analysis, we recommend the sliding mode control components SMCt as following: ( ) 2 2 2 T SMC T Z Z j lt j hl= + (25) Where h is a positive scalar control gain: , (0) 0hh h h= -X >! (26) With [ ]1 2 3 4 , , , Tj j j j j= is a bound of vector *j . Based on (25) and (26). Adaptive sliding mode control components ˆASMCt is shown as follows: ( ) 2 2 2 ˆ ˆ ˆ T ASMC T Z Z ljt j hl= + (27) Where jˆ is the estimate of *j . The proportional-integral controller PIt is designed by: 2 2 0 PI P IK Z K Z dt t t = + ò (28) (23) Fig 2. The architecture of the RM control system 26 NGHIÊN CỨU KHOA HỌC Tạp chí Nghiên cứu khoa học, Trường Đại học Sao Đỏ, ISSN 1859-4190, Số 3 (70) 2020 Where PK and IK are proportional and integral term gains, respectively. Because PK and IK are adjustable adaptive parameters. For the convenience of presenting PIt in (28) it can be denoted adaptive proportional–integral controller ˆAPIt in the form: ˆˆ TAPI PI PIK ht = Where 22 2 2( ) [ , ]PIh Z Z Z dt R= ò Î is a regressive vector and 2[ , ]PI P IK K K R= Î is the parameter vector that can be adjusted simultaneously with the system. Applying (23) to (18), yields: ( ) ( ) ( ) 2 2 2 1 ˆ ˆ ˆˆ ˆ ˆ T T T T T IRM T T T T T IRM SMC T PI T M Z Б Б C Z Z E D W g a p u g a z c z µ t t p u = - -G ¡ -L + +G ¡ +L + - + - - - - + F - + Y ! ! ! " ! !! ! (29) Based on (16), (25) and (28). The online adaptive update laws of RAFNNs are designed as: 2 2 2 2 2 2 2 2 2 ˆ ˆ ˆ ˆ ˆˆ( ) ˆˆ ˆˆ ˆˆ ˆˆ ˆ ˆ ˆ ˆ T T T T T E E E PI PI PI T T T T T Б Z Б Z Z Z Z Z E K Z h Z E Z z g a p u j h z c g a p u g z a z p z u z j l hh n ì = X - -G - ¡ -Lïï = Xï = X Gïï = X ¡ïï = X Líï = Xïïïïïï = -X = X Y -X = Xî ! ! ! ! ! ! ! ! ! (30) Here ,, , , ,, ,, E PIz g a p u j hX XX X X X XX X are positive adaptation rates. 3.2. Stability Analysis Theorem 1 Consider a ARNNs adaptive control rule n-links IRM (1) designed in equation (16), robust control component SMCt in (25), the proportional-integral controller PIt is defined in (28), and adaptive parameters automatically adjusted corrected by Equation (30), the position error converges to zero as t approaches infinity. Select the function lyapunov as follows: 2 2 2 2 2 2 2 2 2 ˆ ˆ ˆ ˆ ˆˆ( ) ˆˆ ˆˆ ˆˆ ˆˆ ˆ ˆ ˆ ˆ T T T T T E E E PI PI PI T T T T T Б Z Б Z Z Z Z Z E K Z h Z E Z z g a p u j h z c g a p u g z a z p z u z j l hh n ì = X - -G - ¡ -Lïï = Xï = X Gïï = X ¡ïï = X Líï = Xïïïïïï = -X = X Y -X = Xî ! ! ! ! ! ! ! ! ! (31) The derivative over time of ( )L t , we get: 1 2 1 1 2 2 2 2 1( ) ( ) 2 1 1ˆ ˆ 1 1 1ˆ ˆˆ 1 1ˆ 1 1ˆ ˆ( ) T T IRM T T T IRM T T T T T T PI PI E PI L t Z Z Z Z M Z Z M Z tr E E K K z g a p u j h µ x z g g a a p p u u j j h = - + + - -X X - - -X X X - +X X - -X X " " " "!" ! " ""! !! "! " " "! ! (32) Substitute (29) into (32) and using property 2, we obtain: 1 2 1 1 2 2 2 2 1( ) ( ) 2 1 1ˆ ˆ 1 1 1ˆ ˆˆ 1 1ˆ 1 1ˆ ˆ( ) T T IRM T T T IRM T T T T T T PI PI E PI L t Z Z Z Z M Z Z M Z tr E E K K z g a p u j h µ x z g g a a p p u u j j h = - + + - -X X - - -X X X - +X X - -X X " " " "!" ! " ""! !! "! " " "! ! (33) Substituting the online adaptive update law (30) to (33), yields: ( ) ( ) ( ) ( )( )2 1 1 1 2 2 2 2 2 2 2 2ˆ τ T T T T T T SMC T T PI P PI T T D I L t Z Z Z Z Z W Z E E Z K Z h tr D Z D Z µ µ t j l h aQ Q Y = - - + - - - + - - - - - X - F! ! ! !! " (34) 27 LIÊN NGÀNH ĐIỆN - ĐIỆN TỬ - TỰ ĐỘNG HÓA Tạp chí Nghiên cứu khoa học, Trường Đại học Sao Đỏ, ISSN 1859-4190, Số 3 (70) 2020 By using (24), (25) and (28), it becomes: ( ) ( )( ) 2 1 1 1 2 2 2 2 2 ˆ ˆ ˆ T T T T T E T ZL t Z Z Z Z Z tr E Z Ev lh j µ µ h j hl h £ - - + + - + -F! " Because 2 2 ˆ 0ˆ T T Z Z h l l j hh j h - <+ , therefore (35) becomes ( ) ( )( )( ) 1 1 1 2 2 2 2 T E T T T L t Z Z Z Z tr E Z E Ev µ µ£ - - + - -F! ! " (36) By using ( ) ( ) 2 2,TtrE E E E E E E E E- = - £ -! ! ! ! ! ! and using the inequality (17) into (36) could be rewritten as follows: 1 1 1 2 2 2 2 0 2 2E T TL Z Z Z Z c Z E v Z E µ µ£ - - + -! ! " (37) With 0 Ec n Ev= + . We see that to make sure 0L £! . From the results show that the system is stable. 4. SIMULATION RESULTS The structure of the n-links IRM is quite complicated in [19]. Fig 3. Architecture of three-link De-icing RM According to practical model of three-link de-icing IRM, the parameters of this system are shown as follow: m1 = 3 (kg), m2 = 2 (kg), m3 = 2,5 (kg), l1 = 0,14 (m), l2 = 0,32 (m), and g = 9,81 (m/s2). The desired trajectories of joint for the three-link de-icing IRM are selected as follows: [ ] ( ) ( ) ( ) 1 2 3 sin 1.5 0 ;.5sin 2 sin 1.5 T d d d d Tt t t dQ = Q Q = é ùë û The ARNNs controller has the parameter values selected as follows: , ; ; ; ( )1 22,2,2 ; (5,5,5);diag diagµ µ= = ( ) 60, 60, 60, 60, 60 ;diagzX = 0.001PIX = ( )0.001,0.001,0.001,0.001, 0.001 ;diagjX = 0.13gX = 0.12;hX = 0.1aX = 0.1pX = 0.1uX = 10EX = 0.2.Ev = The initial condition is chosen as follows: , , ( )0 1h = ( ) [ ] 0 1 1 1 1 l = ( )0 1.E = Comparative results of the proposed ARNNs controller with the AF [3] and PID controllers are shown in Figure 4 and Table 1. We see that all three controllers achieve global stability, tracking error is very small around zero, the ability to respond quickly, the overshoot is insignificant. However, the proposed controller is capable of responding faster and with less overshoot than the AF and PID controllers. The errors that follow the desired trajectory of the proposed RANNs controller are smaller than the AF and PID controllers. That is, the proposed controller has the parameters that have been best adjusted based on the control law and update rules. The ability to approximate unknown functions of the ARNNs controller is also better. The durability of the SMC controller is also shown. Not only that, the PI controller also makes the overshoot of ARNNs improved compared to the two AF and PID controllers. In addition Fig 4 also observes that the control force of the ARNNs is smoother and the vibration is smaller than that of the AF and PID controller even when the tracking error reaches a large value. Table 1. Performance comparisons of proposed controller, PID and AF Simulation Unit: radLink 1 Link 2 Link 3 Proposed controller 2.425×10-4 2.214×10-4 2.857 ×10-4 AF 5.756 ×10-4 5.548 ×10-4 5.945 ×10-4 PID 4.842 ×10-3 3.952 ×10-3 4.846 ×10-3 (35) 28 NGHIÊN CỨU KHOA HỌC Tạp chí Nghiên cứu khoa học, Trường Đại học Sao Đỏ, ISSN 1859-4190, Số 3 (70) 2020 Figure 4. Trajectory, tracking errors, and control input of the AF, PID and proposed ARNNs system 5. CONCLUSIONS In this research, a sustainable adaptive controller to control the three links de-icing IRM on the basis of neural, ASMC, and API controllers has ensured stability and stability in disturbed and changing environments. By using the stability theory of Lyapunov, the authors have proved that the system is always stable throughout the workspace. Moreover, the effectiveness of the controller is also demonstrated through simulation and experiment results when comparing the proposed controller with AF and PID. The simulation results show that the convergence speed, braking ability, grip error, stability, fast response, overshoot of the proposed ARNNs controller are better than the AF controller and the PID control. REFERENCES [1] Jafarov, E.M., Parlakçı, M.N.A., and Istefanopulos. Y (2005), A New Variable Structure PID-Controller Design for Robot Manipulators, IEEE Trans. on control systems technology. 13 (1), pp 122-130. [2] Al-Qahtani. H.M., Mohammed, Amin A., Sunar, M. (2017, Dynamics and control of a robotic arm having four links. Arabian journal for Science and Engineering, 42(5), pp. 1841-1852. [3] Mohammad R S, Pooria O, Mohammad H K. (2015), Robust control strategy for electrically driven robot manipulators: adaptive fuzzy sliding mode, IET Sci. Meas. Technol. 9(3): 322-334. [4] Han, S., Lee, J. (2016), Finite-time sliding surface constrained control for a robot manipulator with an unknown deadzone and disturbance, ISA Transactions, vol. 65, pp. 307-318. [5] Cao L. J., Wang Y. C., Zhang S. X. et al. (2016), Robust Adaptive Backstepping Control for a Class of Uncertain Nonlinear System. Ieee. [6] Lin X., Dong H. R., Yao X. M. (2018), Tuning function-based adaptive backstepping fault- tolerant control for nonlinear systems with actuator faults and multiple disturbances, Nonlinear Dynamics. 91(4): 2227-2239. [7] Yang H. J., Ye D. (2018), Fixed-time stabilization of uncertain strict-feedback nonlinear systems via a bi-limit-like strategy, International Journal of Robust and Nonlinear Control. 28(17): 5531-5544. [8] Khorashadizadeh S., Sadeghijaleh M. (2018), Adaptive fuzzy tracking control of robot manipulators actuated by permanent magnet synchronous motors, Computers & Electrical Engineering, vol. 72, pp. 100-111. [9] Karamali Ravandi, Khanmirza E. and Daneshjou K. (2018), Hybrid force/position control of robotic arms manipulating in uncertain environments based on adaptive fuzzy sliding mode control, Applied Soft Computing, vol. 70, pp. 864-874. [10] Peng J. and Dubay R. (2019), Adaptive fuzzy backstepping control for a class of uncertain nonlinear strict-feedback systems based on dynamic surface control approach, Expert Systems with Applications, vol. 120, pp. 239-252. 29 LIÊN NGÀNH ĐIỆN - ĐIỆN TỬ - TỰ ĐỘNG HÓA Tạp chí Nghiên cứu khoa học, Trường Đại học Sao Đỏ, ISSN 1859-4190, Số 3 (70) 2020 [11] He J.,Luo M., Zhang Q., Zhao J. and Xu L. (2016), Adaptive Fuzzy Sliding Mode Controller with Nonlinear Observer for Redundant Manipulators Handling Varying External Forc, Journal of Bionic Engineering. vol. 13, pp. 600-611, 2016. [12] Chen D. D., Wang T. M., Yuan P. J. et al. (2019), A positional error compensation method for industrial robots combining error similarity and radial basis function neural network, Measurement Science and Technology. 30(12). [13] Pham C. V., Wang Y. N. (2015), Robust Adaptive Trajectory Tracking Sliding mode control based on Neural networks for Cleaning and Detecting Robot Manipulators, Journal of Intelligent & Robotic Systems. 79(1): 101-114. [14] Yen V. T., Nan W. Y., Cuong P. V. (2019), Robust Adaptive Sliding Mode Neural Networks Control for Industrial Robot Manipulators, International Journal of Control Automation and Systems, 17(3): 783-792. [15] Wu Y., Huang R., Li X. et al. (2019), Adaptive neural network control of uncertain robotic manipulators with external disturbance and time-varying output constraints, Neurocomputing. 323: 108-116. [16] Luan F. J., Na J., Huang Y. B. et al. (2019), Adaptive neural network control for robotic manipulators with guaranteed finite-time convergence, Neurocomputing. 337: 153-164. [17] Vũ Thị Yến, Wang Yao Nan, Lê Thị Hồng Nhinh, Lương Thị Thanh Xuân (2017), Thiết kế bộ điều khiển thích nghi trượt bền vững trên cơ sở mờ nơron cho robot công nghiệp, Tạp chí Nghiên cứu khoa học – Đại học Sao Đỏ, Việt Nam. [18] Vu D. H., Huang S., Tran T. D. et al (2019), A Robust Adaptive Control using Fuzzy Neural Network for Robot Manipulators with Dead- Zone, International Journal of Computers, Communications & Control. 14(5). [19] Van Tran, T., Wang, Y., Ao, H., & Khac Truong, T. (2015), Sliding mode control based on chemical reaction optimization and radial basis functional link net for de-icing robot manipulator, Journal of Dynamic Systems, Measurement, and Control, 137(5). Tran Thi Diep - Summary of the training and research process (graduation time and training program, research): + In 2010: She received her B.S in Automation Engineering from Thai Nguyen University of Technology, Thai Nguyen Vietnam. + In 2013 : Graduated with Master degree in Automation from Hanoi University of Mining and Geology, Hanoi Vietnam. + In 2020: Graduated with a doctorate in electrical engineering from Hunan University, China. - Summary of current work: Lecturer, Faculty of Electrical at Sao Do University. - Areas of concern: Her current research interests include control nonlinear systems including SIMO and MIMO and control of distributed generation systems using renewable energy sources. - Email: phuongdiep222@hnu.edu.cn. - Phone number: 0374700015. AUTHORS BIOGRAPHY

File đính kèm:

thiet_ke_bo_dieu_khien_mang_neural_thich_nghi_ben_vung_cho_t.pdf

thiet_ke_bo_dieu_khien_mang_neural_thich_nghi_ben_vung_cho_t.pdf