Modified atmosphere packaging reduces pericarp browning and maintains the quality of "Huong Chi" longan fruit (Dimocarpus longan) pretreated with citric acid

Longan ‘Huong Chi’ (Dimocarpus longan Lour.) is one of the most

favorite and widely exported fruits in Vietnam, but the trading of

longan faces considerable challenges due to rapid pericarp browning

and decay. Our study aimed to determine the effects of modified

atmospheres generated by low-density polyethylene (LDPE),

polypropylene bag (PP), and LifeSpan L201 films on the quality and

pericarp browning of ‘Huong Chi’ longan fruit pre-treated with 3.0

% citric acid and stored at 5oC. The results showed that LifeSpan

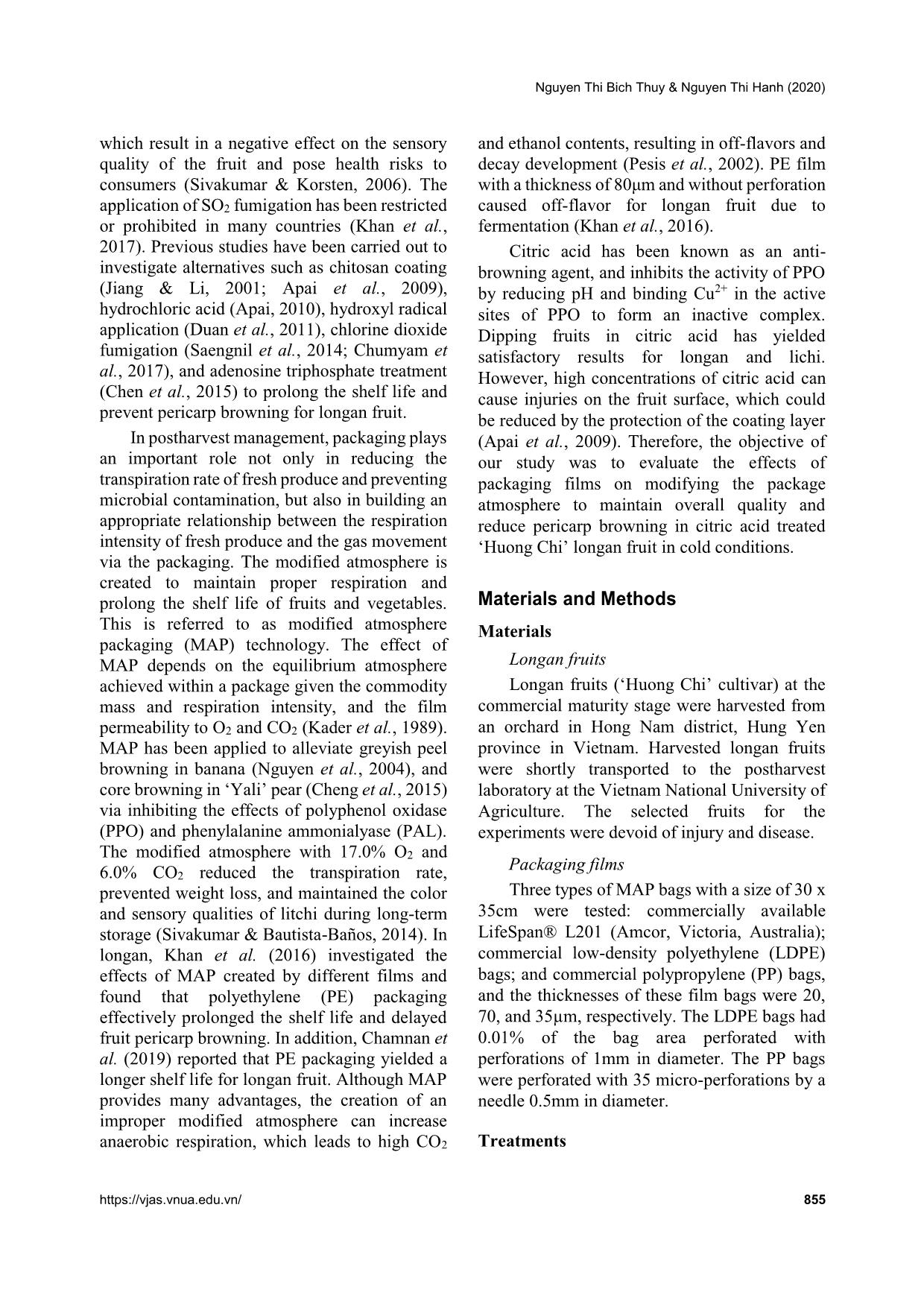

L201 and LDPE packaging created an equilibrium atmosphere of

10.66 ± 0.78% O2, 4.44 ± 0.64% CO2, and 15.04 ± 0.89% O2, 2.96 ±

0.61% CO2, respectively. The modified atmospheres generated by

LifeSpan L201 and LDPE delayed pericarp browning, maintained the

total soluble solids (TSS) and vitamin C content, and reduced decay

in longan fruit. Meanwhile, the PP packaging resulted in an

improperly modified atmosphere which led to severe decay and

browning in cold storage conditions.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tóm tắt nội dung tài liệu: Modified atmosphere packaging reduces pericarp browning and maintains the quality of "Huong Chi" longan fruit (Dimocarpus longan) pretreated with citric acid

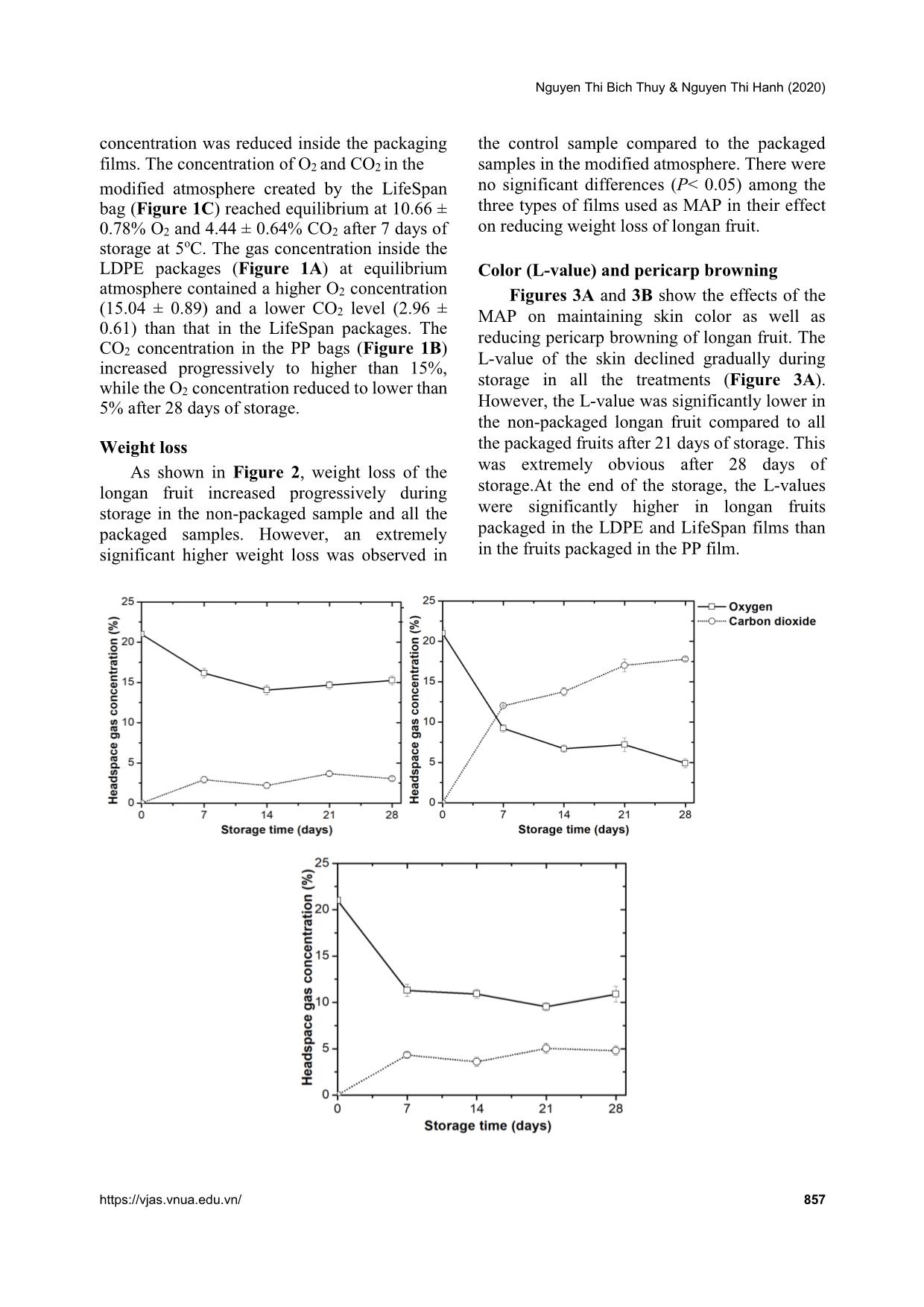

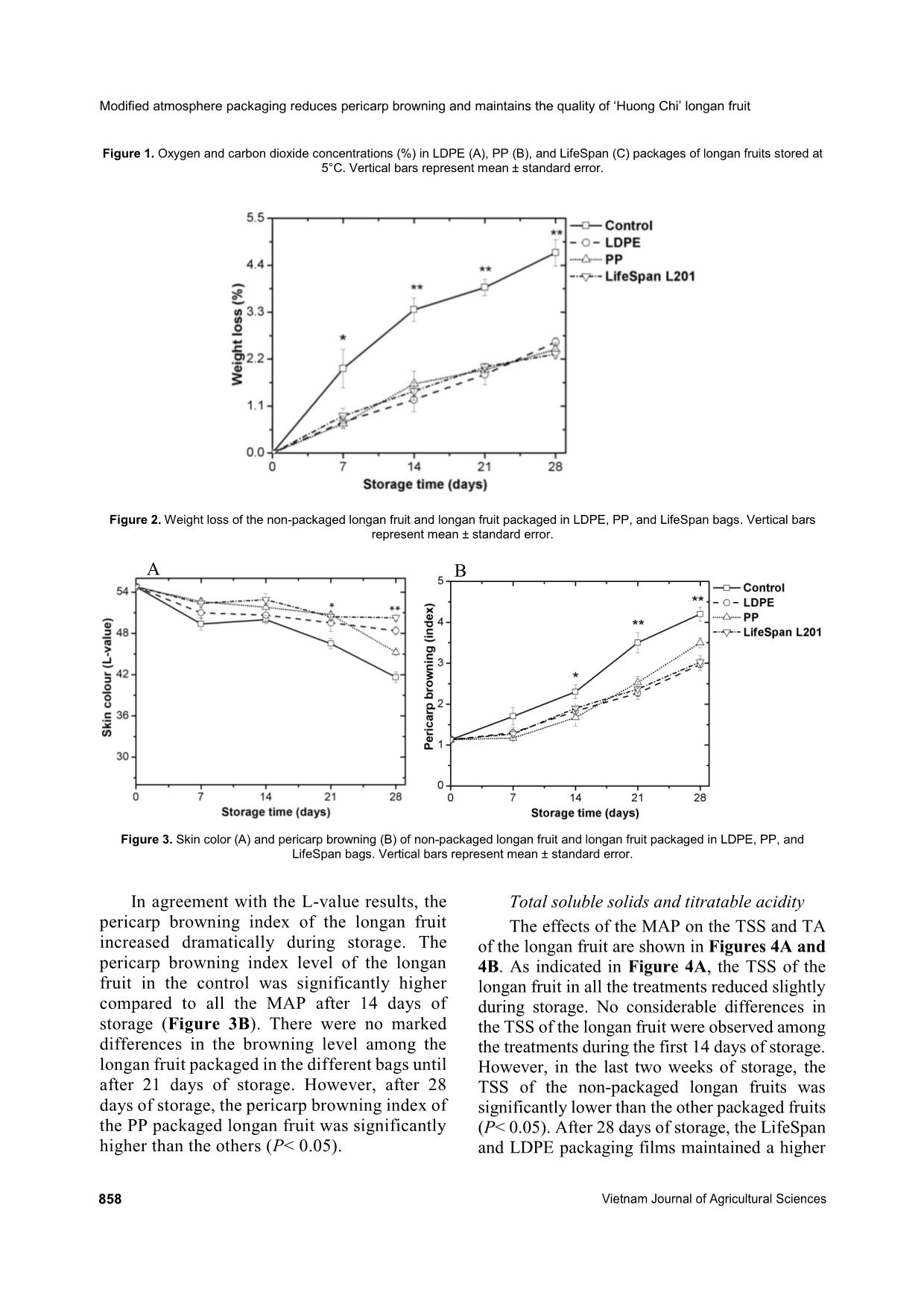

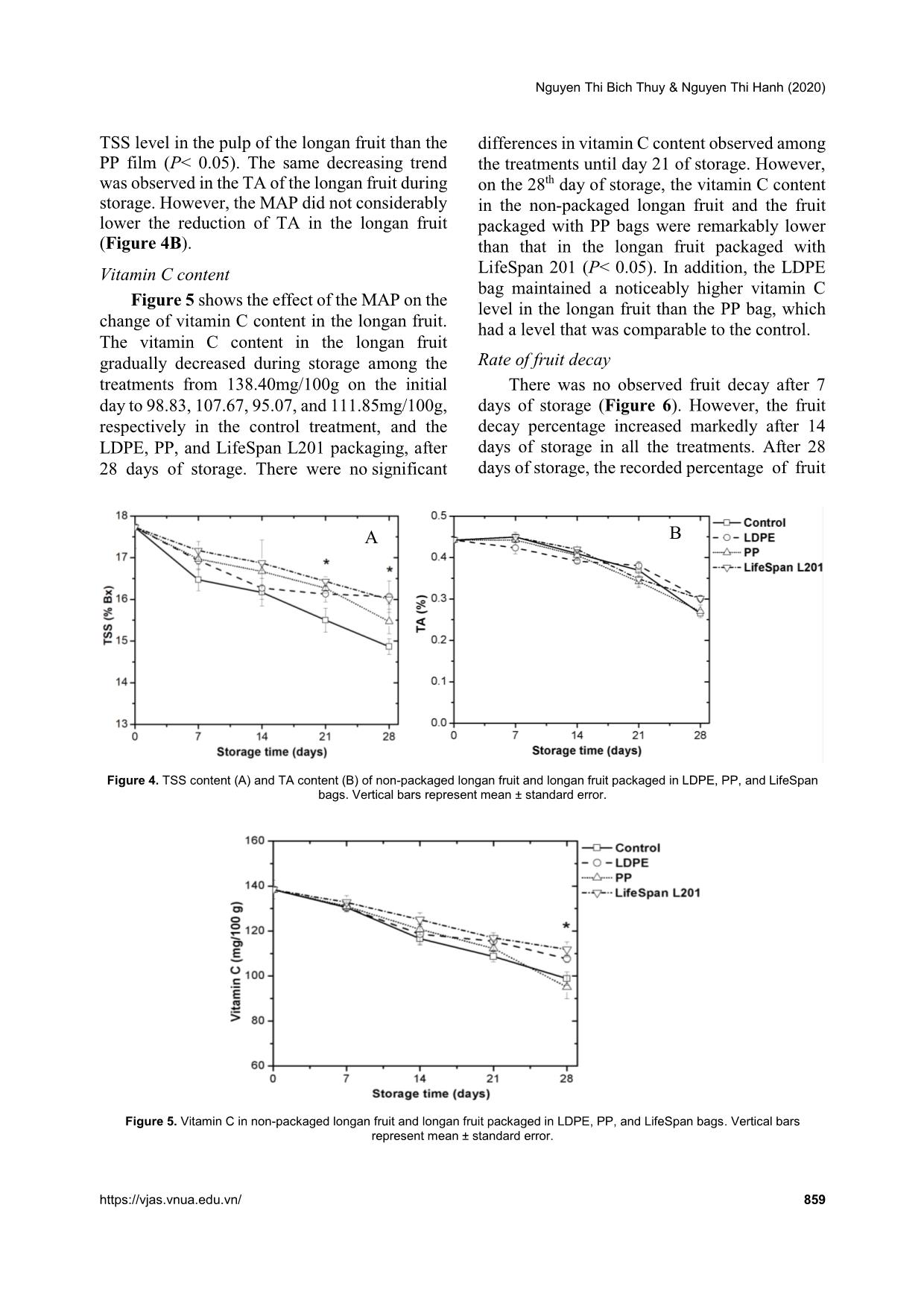

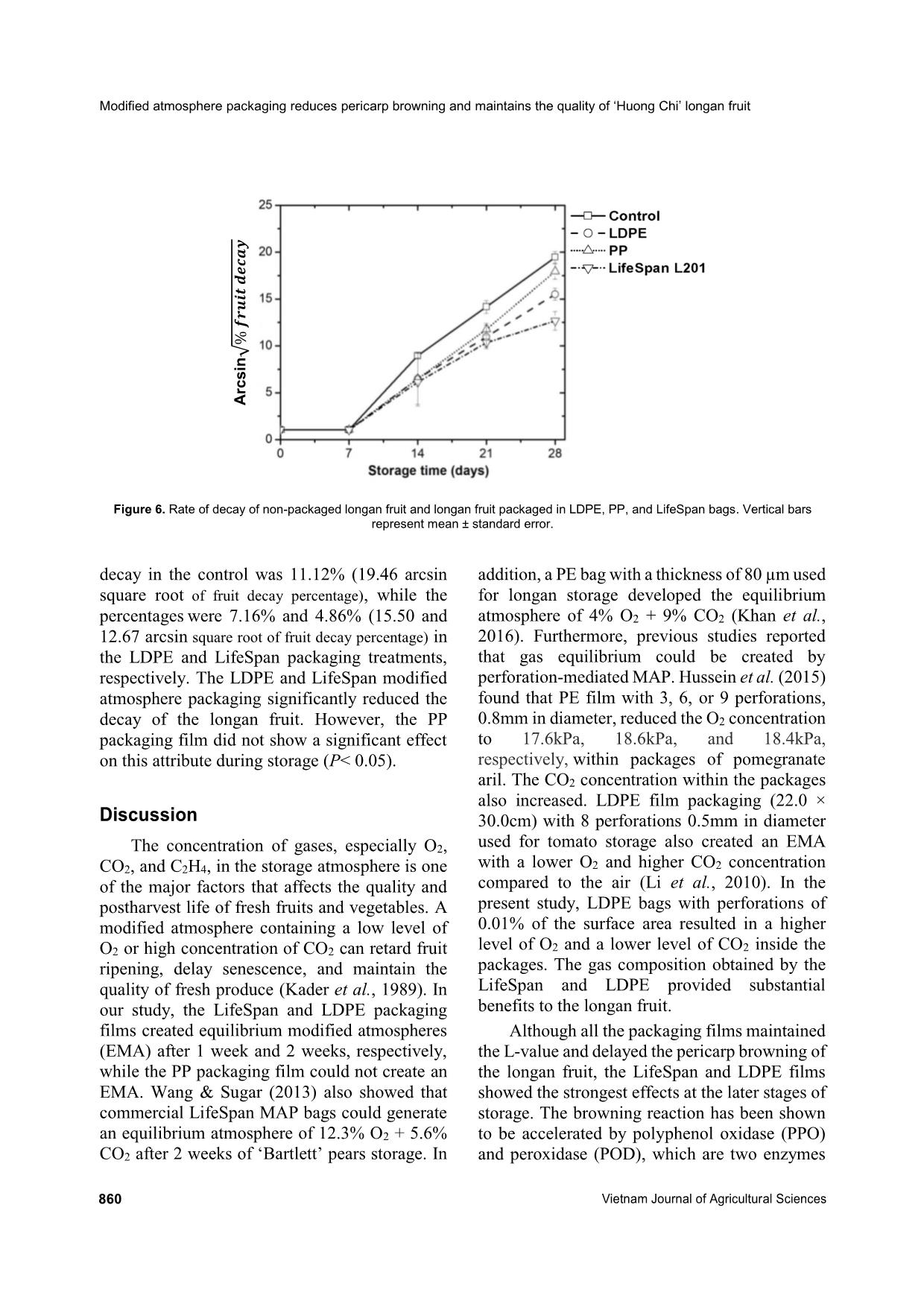

treatment, and the LDPE, PP, and LifeSpan L201 packaging, after 28 days of storage. There were no significant differences in vitamin C content observed among the treatments until day 21 of storage. However, on the 28th day of storage, the vitamin C content in the non-packaged longan fruit and the fruit packaged with PP bags were remarkably lower than that in the longan fruit packaged with LifeSpan 201 (P< 0.05). In addition, the LDPE bag maintained a noticeably higher vitamin C level in the longan fruit than the PP bag, which had a level that was comparable to the control. Rate of fruit decay There was no observed fruit decay after 7 days of storage (Figure 6). However, the fruit decay percentage increased markedly after 14 days of storage in all the treatments. After 28 days of storage, the recorded percentage of fruit Figure 4. TSS content (A) and TA content (B) of non-packaged longan fruit and longan fruit packaged in LDPE, PP, and LifeSpan bags. Vertical bars represent mean ± standard error. Figure 5. Vitamin C in non-packaged longan fruit and longan fruit packaged in LDPE, PP, and LifeSpan bags. Vertical bars represent mean ± standard error. A B Modified atmosphere packaging reduces pericarp browning and maintains the quality of ‘Huong Chi’ longan fruit 860 Vietnam Journal of Agricultural Sciences Figure 6. Rate of decay of non-packaged longan fruit and longan fruit packaged in LDPE, PP, and LifeSpan bags. Vertical bars represent mean ± standard error. decay in the control was 11.12% (19.46 arcsin square root of fruit decay percentage), while the percentages were 7.16% and 4.86% (15.50 and 12.67 arcsin square root of fruit decay percentage) in the LDPE and LifeSpan packaging treatments, respectively. The LDPE and LifeSpan modified atmosphere packaging significantly reduced the decay of the longan fruit. However, the PP packaging film did not show a significant effect on this attribute during storage (P< 0.05). Discussion The concentration of gases, especially O2, CO2, and C2H4, in the storage atmosphere is one of the major factors that affects the quality and postharvest life of fresh fruits and vegetables. A modified atmosphere containing a low level of O2 or high concentration of CO2 can retard fruit ripening, delay senescence, and maintain the quality of fresh produce (Kader et al., 1989). In our study, the LifeSpan and LDPE packaging films created equilibrium modified atmospheres (EMA) after 1 week and 2 weeks, respectively, while the PP packaging film could not create an EMA. Wang & Sugar (2013) also showed that commercial LifeSpan MAP bags could generate an equilibrium atmosphere of 12.3% O2 + 5.6% CO2 after 2 weeks of ‘Bartlett’ pears storage. In addition, a PE bag with a thickness of 80 µm used for longan storage developed the equilibrium atmosphere of 4% O2 + 9% CO2 (Khan et al., 2016). Furthermore, previous studies reported that gas equilibrium could be created by perforation-mediated MAP. Hussein et al. (2015) found that PE film with 3, 6, or 9 perforations, 0.8mm in diameter, reduced the O2 concentration to 17.6kPa, 18.6kPa, and 18.4kPa, respectively, within packages of pomegranate aril. The CO2 concentration within the packages also increased. LDPE film packaging (22.0 × 30.0cm) with 8 perforations 0.5mm in diameter used for tomato storage also created an EMA with a lower O2 and higher CO2 concentration compared to the air (Li et al., 2010). In the present study, LDPE bags with perforations of 0.01% of the surface area resulted in a higher level of O2 and a lower level of CO2 inside the packages. The gas composition obtained by the LifeSpan and LDPE provided substantial benefits to the longan fruit. Although all the packaging films maintained the L-value and delayed the pericarp browning of the longan fruit, the LifeSpan and LDPE films showed the strongest effects at the later stages of storage. The browning reaction has been shown to be accelerated by polyphenol oxidase (PPO) and peroxidase (POD), which are two enzymes A rc s in ξ % 𝒇 𝒓 𝒖 𝒊𝒕 𝒅 𝒆 𝒄𝒂 𝒚 * Nguyen Thi Bich Thuy & Nguyen Thi Hanh (2020) https://vjas.vnua.edu.vn/ 861 that convert phenolic compounds to o-quinones, and phenylalanine ammonia lyase (PAL), which catalyzes the biosynthesis of phenolic compounds (Nguyen et al., 2004; Khan et al., 2016). In agreement with our study, a modified atmosphere with 12% oxygen and 4% CO2 inhibited PPO and PAL activities resulting in less peel browning in banana (Nguyen et al., 2004). The modified atmosphere of 17% O2 and 6% CO2 created by perforated PP packaging was also reported to reduce pericarp browning in litchi (Sivakumar & Korsten, 2006). The results in our study suggested that the effects of the LifeSpan and LDPE films on reducing pericarp browning in longan fruit may involve the inhibition of enzyme activities. Moreover, pericarp browning in longan fruit has also been shown to be associated with desiccation (Jiang et al., 2002), which rapidly occurs after harvest. In the present study, all the packages significantly reduced the desiccation of the longan fruit, which was reflected in weight loss reduction. Hence, the pericarp browning of packaged fruits was inhibited as a consequence. In addition, it was observed that the L-value was maintained in the non-packaged fruit during the first 2 weeks of storage, which may support the effects of the citric acid treatment as an anti-browning agent. Even though, longan fruit is a non- climacteric fruit, the TSS and TA were shown to decrease gradually after harvest, even in cold storage conditions (Jiang et al., 2002). All packaging films in our study reduced the loss of the TSS in longan fruit, but the LDPE and LifeSpan films showed higher effects than the PP after 28 days of storage. The effect of the MAP on the TSS was probably due to the low concentration of O2 and high level of CO2 atmosphere which reduced respiratory metabolism, resulting in decreased consumption of the TSS as substrates. At the end of storage, the loss of the TSS content in the longan fruit packaged in PP bags was more rapid. This could have been caused by anaerobic respiration occurring inside the PP bags due to undesirable atmosphere conditions with too low O2 and high CO2 concentrations. In agreement with our results, Khan et al. (2016) found that PE films maintained the TSS and TA contents in longan fruits, while the PP film led to a higher reduction of the TSS and TA. On the other hand, the MAP created by the LDPE and LifeSpan L201 films provided a preserving effect on vitamin C content in longan fruit, which was not obtained by the PP film. The present study agrees with Wang & Sugar (2013), who reported that commercial LifeSpan L254 suppressed the loss of ascorbic acid during storage via reducing membrane leakage. Modified atmosphere packaging and a controlled atmosphere were determined to decrease oxidative stress through the retention of ascorbic acid in fruits and vegetables (Hodges et al., 2004). The optimum gas composition in the storage atmosphere can suppress fungal decay of fruit, but the undesired modified atmosphere created by PP packaging film may cause physiological disorders, which could be followed by disease symptoms (Khan et al., 2016). In our study, the PP packaging film could not decrease the fruit decay compared to the control, which is the extent of the above discussion. Meanwhile, the LDPE and LifeSpan films strongly reduced the decay of the longan fruit after 4 weeks of storage. These results were in agreement with the studies on litchi and sweet cherry that reported that the appropriate MAP can reduce fruit decay, which was related to the inhibitory effect on the growth of disease pathogens (Sivakumar & Korsten, 2006; Wang et al., 2015). Conclusions The LDPE and LifeSpan packaging films not only prevented the desiccation but also created the optimum EMA for the storage of longan fruit. This EMA significantly reduced pericarp browning, maintained the TSS content, reduced the loss of vitamin C, which contributes to the edible quality of fruit, and minimized fruit decay during cold storage. The PP packaging produced an undesired modified atmosphere for longan fruit, which resulted in severe decay symptoms and browning at the end of storage. Fruit stored in LifeSpan packaging films had the longest shelf life of 28 days, with a browning index less than 3, and a percentage of fruit decay Modified atmosphere packaging reduces pericarp browning and maintains the quality of ‘Huong Chi’ longan fruit 862 Vietnam Journal of Agricultural Sciences less than 5%. This MAP extended the shelf life of the longan fruit more than 7 days longer than the control. Acknowledgments This study was funded by the “Development of innovative technologies on postharvest management for longan fruit fulfilling the requirement of domestic trading and exporting” project, No. 739/HD-BNN-KHCN, Ministry of Agriculture and Rural Development, Vietnam. References Apai W. (2010). Effects of fruit dipping in hydrochloric acid then rinsing in water on fruit decay and browning of longan fruit. Crop Protection. 29(10): 1184-1189. Apai W., Sardsud V., Boonprasom P. & Sardsud U. (2009). Effects of chitosan and citric acid on pericarp browning and polyphenol oxidase activity of longan fruit. Songklanakarin Journal of Science & Technology. 31(6): 621-628. Chamnan S., Varith J., Jaturonglumlert S., Klinkajorn P. & Phimphimol J. (2019). The effect of packaging materials on the quality of freshness of longan fumigated with medium concentration-ozone gas. Pertanika Journal of Science and Technology. 27: 159- 168. Chen M., Lin H., Zhang S., Lin Y., Chen Y. & Lin Y. (2015). Effects of adenosine triphosphate (ATP) treatment on postharvest physiology, quality and storage behavior of longan fruit. Food and Bioprocess Technology. 8(5): 971-982. Chen S., Chen J., Hong Q. & Lin H. (2000). Current situation and advances in post-harvest storage and transportation technologies of longan fruit. I International Symposium on Litchi and Longan 558. 343-351. Cheng Y., Liu L., Zhao G., Shen C., Yan H., Guan J. & Yang K. (2015). The effects of modified atmosphere packaging on core browning and the expression patterns of PPO and PAL genes in ‘Yali’pears during cold storage. LWT-Food Science and Technology. 60(2): 1243-1248. Chumyam A., Shank L., Faiyue B., Uthaibutra J. & Saengnil K. (2017). Effects of chlorine dioxide fumigation on redox balancing potential of antioxidative ascorbate-glutathione cycle in ‘Daw’ longan fruit during storage. Scientia Horticulturae. 222: 76-83. Duan X., Zhang H., Zhang D., Sheng J., Lin H. & Jiang Y. (2011). Role of hydroxyl radical in modification of cell wall polysaccharides and aril breakdown during senescence of harvested longan fruit. Food Chemistry. 128(1): 203-207. Hodges D. M., Lester G. E., Munro K. D. & Toivonen P. M. (2004). Oxidative stress: importance for postharvest quality. HortScience. 39(5): 924-929. Hussein Z., Caleb O. J., Jacobs K., Manley M. & Opara U. L. (2015). Effect of perforation-mediated modified atmosphere packaging and storage duration on physicochemical properties and microbial quality of fresh minimally processed ‘Acco’pomegranate arils. LWT-Food Science and Technology. 64(2): 911-918. Jiang Y. & Li Y. (2001). Effects of chitosan coating on postharvest life and quality of longan fruit. Food Chemistry. 73(2): 139-143. Jiang Y., Zhang Z., Joyce D. C. & Ketsa S. (2002). Postharvest biology and handling of longan fruit (Dimocarpus longan Lour.). Postharvest Biology and Technology. 26(3): 241-252. Kader A. A., Zagory D., Kerbel E. L. & Wang C. Y. (1989). Modified atmosphere packaging of fruits and vegetables. Critical Reviews in Food Science and Nutrition. 28(1): 1-30. Khan M. R., Sripethdee C., Chinsirikul W., Sane A. & Chonhenchob V. (2016). Effects of film permeability on reducing pericarp browning, preventing postharvest decay and extending shelf life of modified atmosphere- retail packaged longan fruits. International Journal of Food Science and Technology. 51(8): 1925-1931. Khan M. R., Suwanamornlert P., Leelaphiwat P., Chinsirikul W. & Chonhenchob V. (2017). Quality and biochemical changes of longan (Dimocarpus longan Lour cv. Daw) fruit under different controlled atmosphere conditions. International Journal of Food Science and Technology. 52(10): 2163-2170. Li L., Li X.-H. & Ban Z.-J. (2010). A mathematical model of the modified atmosphere packaging (MAP) system for the gas transmission rate of fruit produce. Food Technology and Biotechnology. 48(1): 71-78. Nguyen T. B. T., Ketsa S. & van Doorn W. G. (2004). Effect of modified atmosphere packaging on chilling- induced peel browning in banana. Postharvest Biology and Technology. 31(3): 313-317. Pesis E., Dvir O., Feygenberg O., Arie R. B., Ackerman M. & Lichter A. (2002). Production of acetaldehyde and ethanol during maturation and modified atmosphere storage of litchi fruit. Postharvest Biology and Technology. 26(2): 157-165. Saengnil K., Chumyam A., Faiyue B. & Uthaibutra J. (2014). Use of chlorine dioxide fumigation to alleviate enzymatic browning of harvested ‘Daw’ longan pericarp during storage under ambient conditions. Postharvest Biology and Technology. 91: 49-56. Sivakumar D. & Bautista-Baños S. (2014). A review on the use of essential oils for postharvest decay control and maintenance of fruit quality during storage. Crop Protection. 64: 27-37. Nguyen Thi Bich Thuy & Nguyen Thi Hanh (2020) https://vjas.vnua.edu.vn/ 863 Sivakumar D. & Korsten L. (2006). Influence of modified atmosphere packaging and postharvest treatments on quality retention of litchi cv. Mauritius. Postharvest Biology and Technology. 41(2): 135-142. Tian S., Xu Y., Jiang A. & Gong Q. (2002). Physiological and quality responses of longan fruit to high O2 or high CO2 atmospheres in storage. Postharvest Biology and Technology. 24(3): 335-340. Wang Y., Bai J. & Long L. E. (2015). Quality and physiological responses of two late-season sweet cherry cultivars ‘Lapins’ and ‘Skeena’ to modified atmosphere packaging (MAP) during simulated long distance ocean shipping. Postharvest Biology and Technology. 110: 1-8. Wang Y. & Sugar D. (2013). Internal browning disorder and fruit quality in modified atmosphere packaged ‘Bartlett’ pears during storage and transit. Postharvest Biology and Technology. 83: 72-82.

File đính kèm:

modified_atmosphere_packaging_reduces_pericarp_browning_and.pdf

modified_atmosphere_packaging_reduces_pericarp_browning_and.pdf