Experimental investigation of hydrodynamic phenomena in vertical-upward adiabatic two-phase Flow Conditions

In order to investigate hydrodynamic phenomena in two-phase flow conditions in nuclear

safety analysis, a series of two-phase flow experiments were conducted using a single flow channel in

which air and water were simultaneously injected into the test section. The experiments under

atmospheric pressure conditions were carried out with the water velocity and the air velocity covering

the ranges from 0.2 to 1.5 m/s and 0.05 to 0.2 m/s, respectively. The technique of two-sensor

conductivity probe was used for the measurement of bubble parameters. The experimental results

presented and analyzed in this study are the local time-averaged void fraction and bubble velocities at

three axial positions L/D = 14.4, 51.2 and 71.3.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

Tóm tắt nội dung tài liệu: Experimental investigation of hydrodynamic phenomena in vertical-upward adiabatic two-phase Flow Conditions

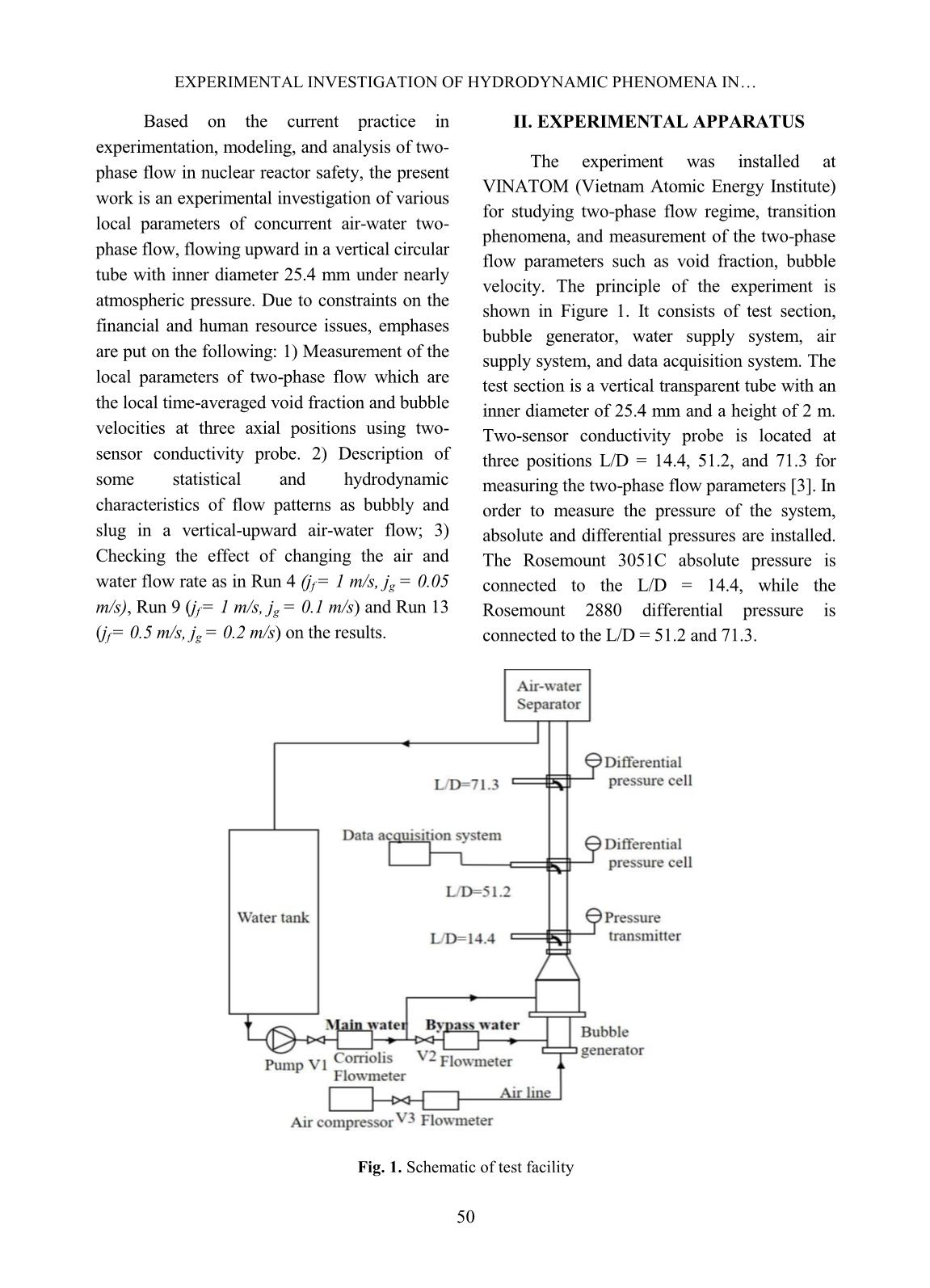

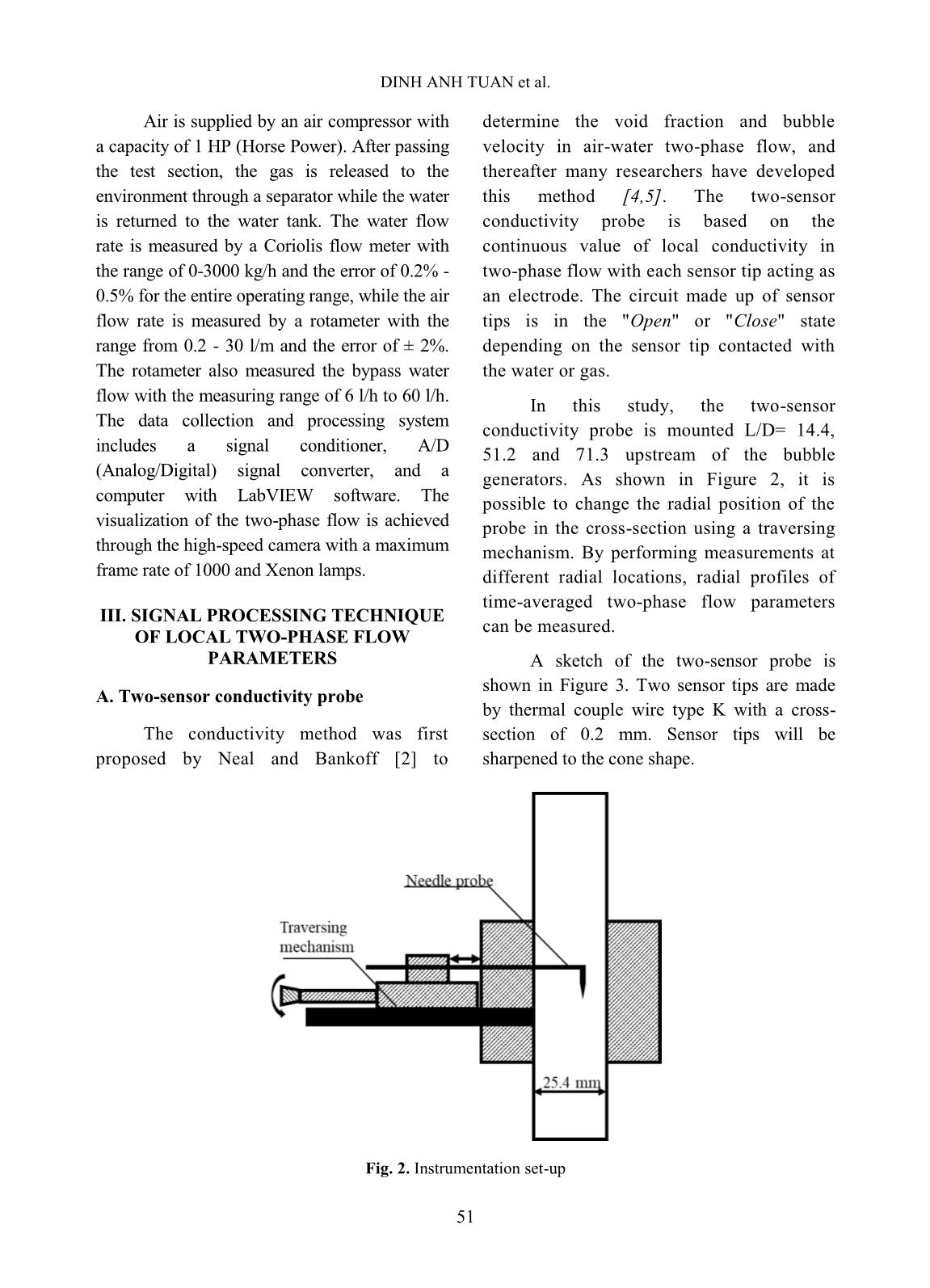

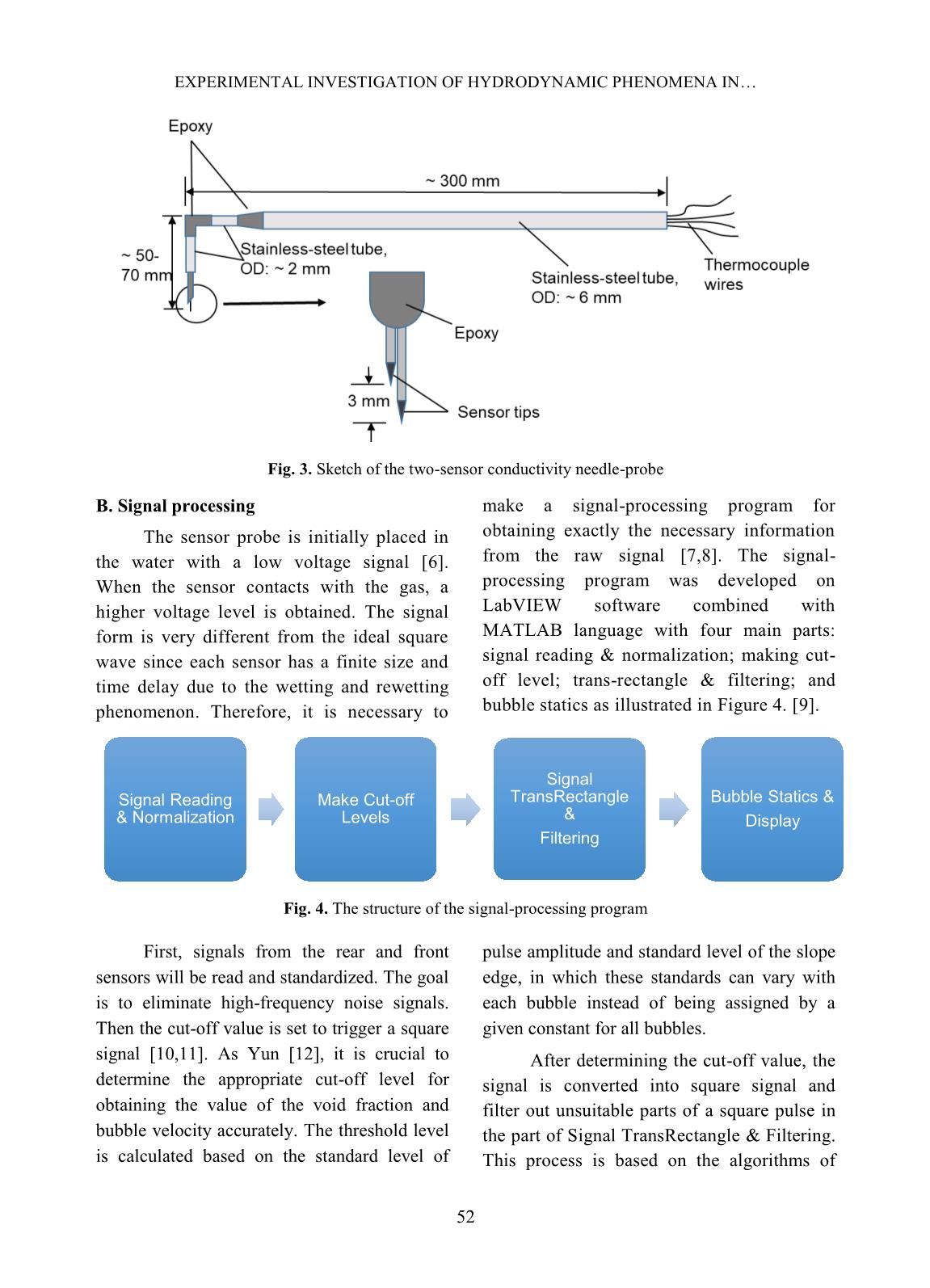

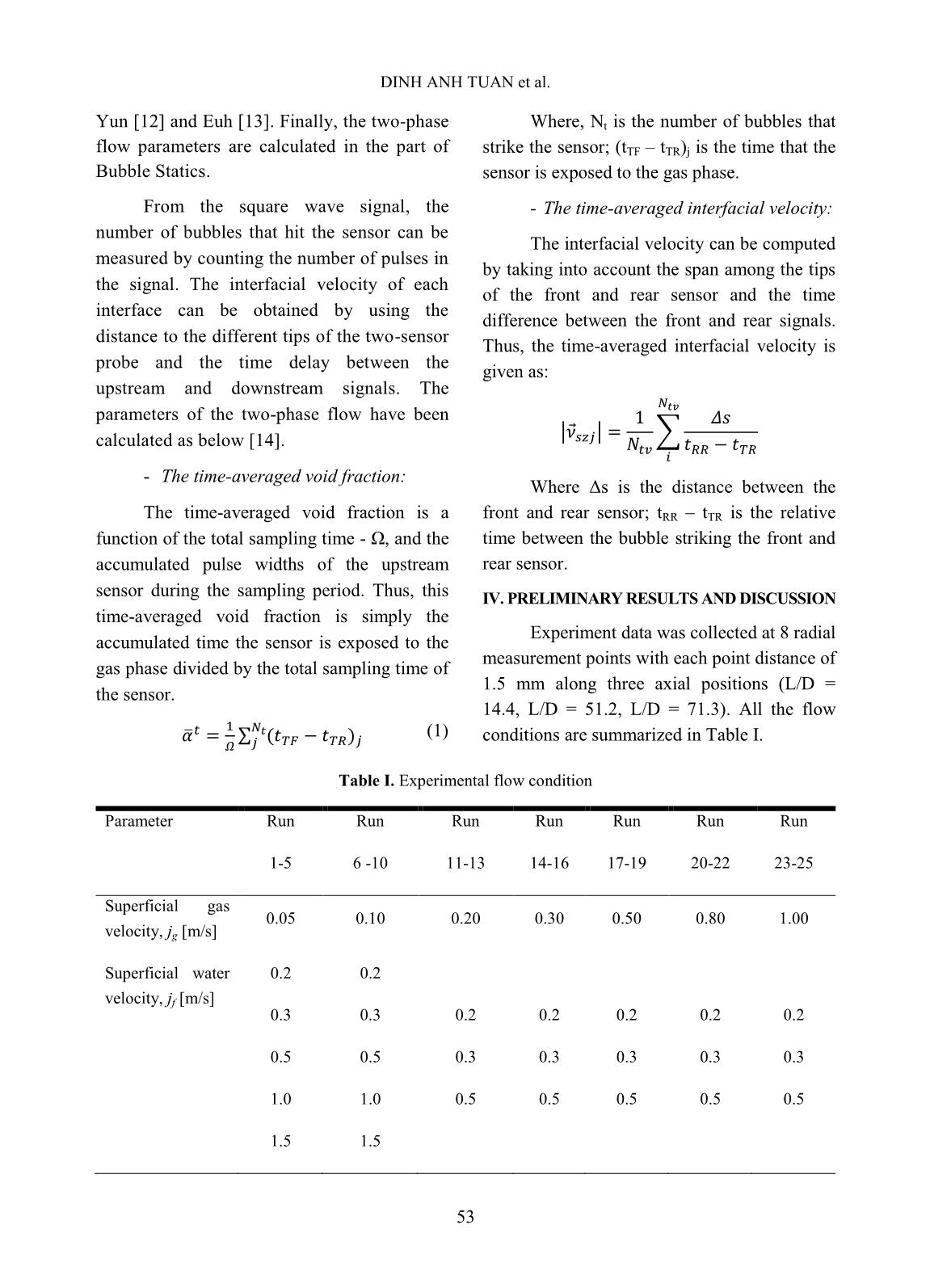

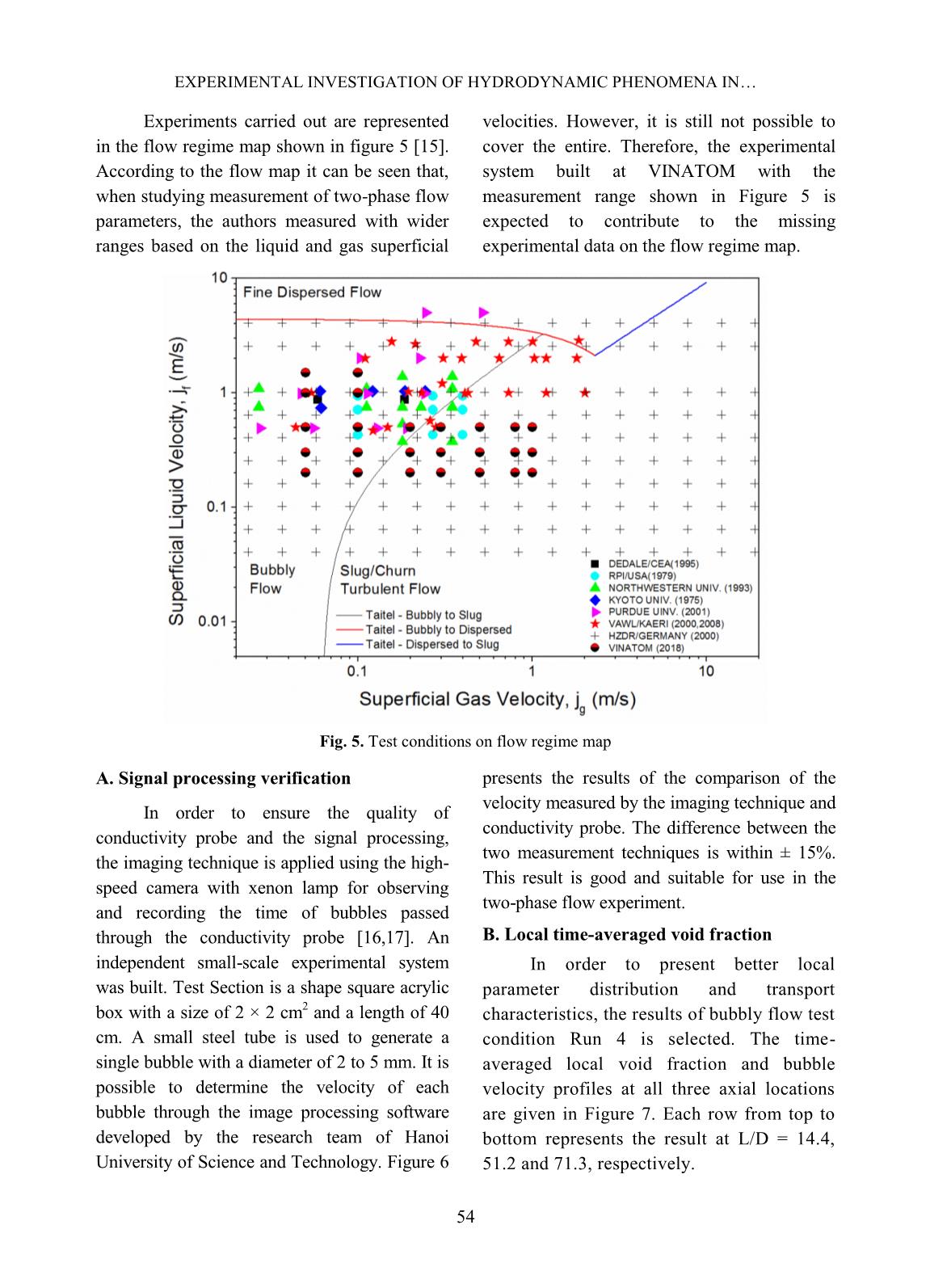

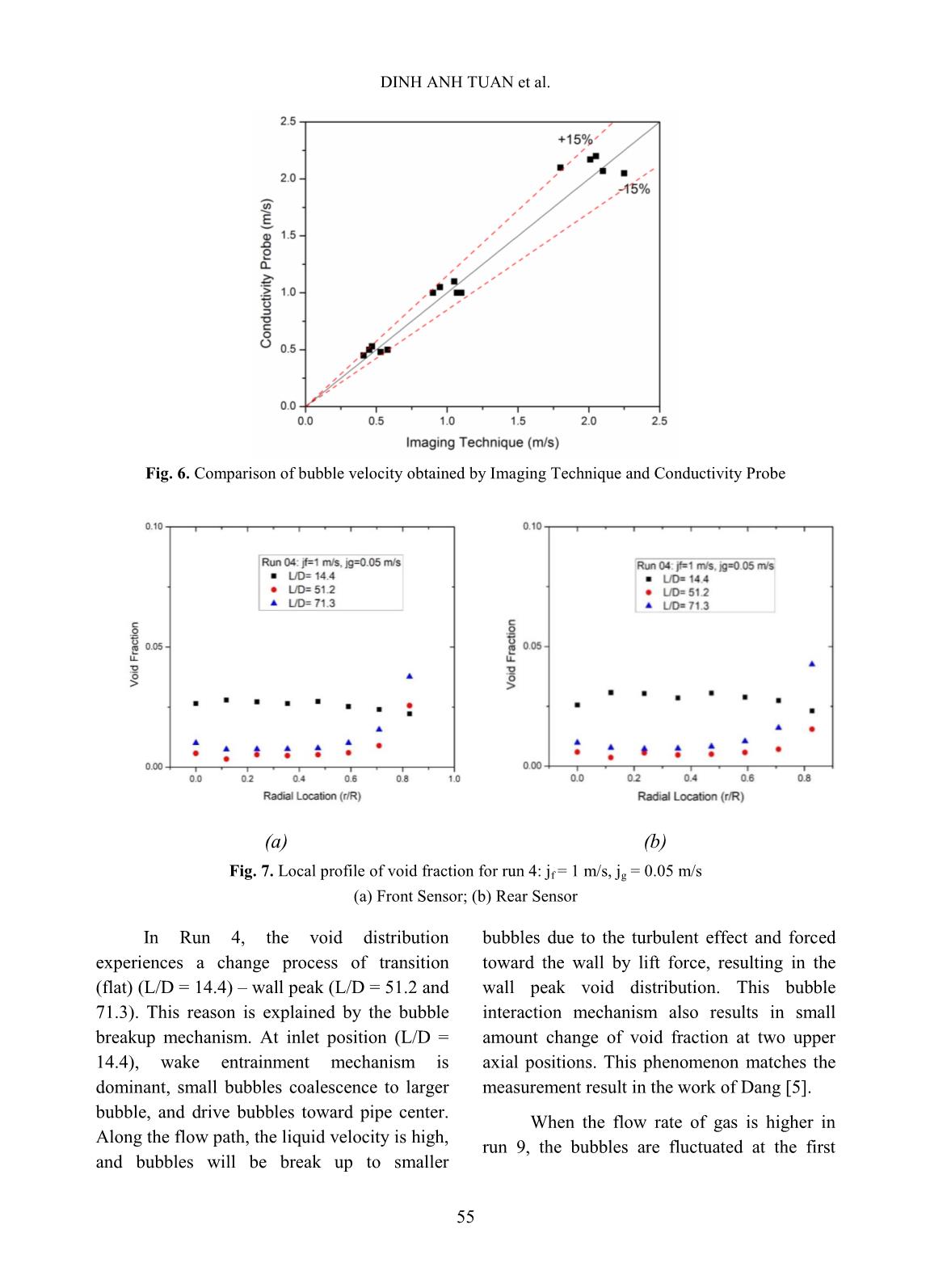

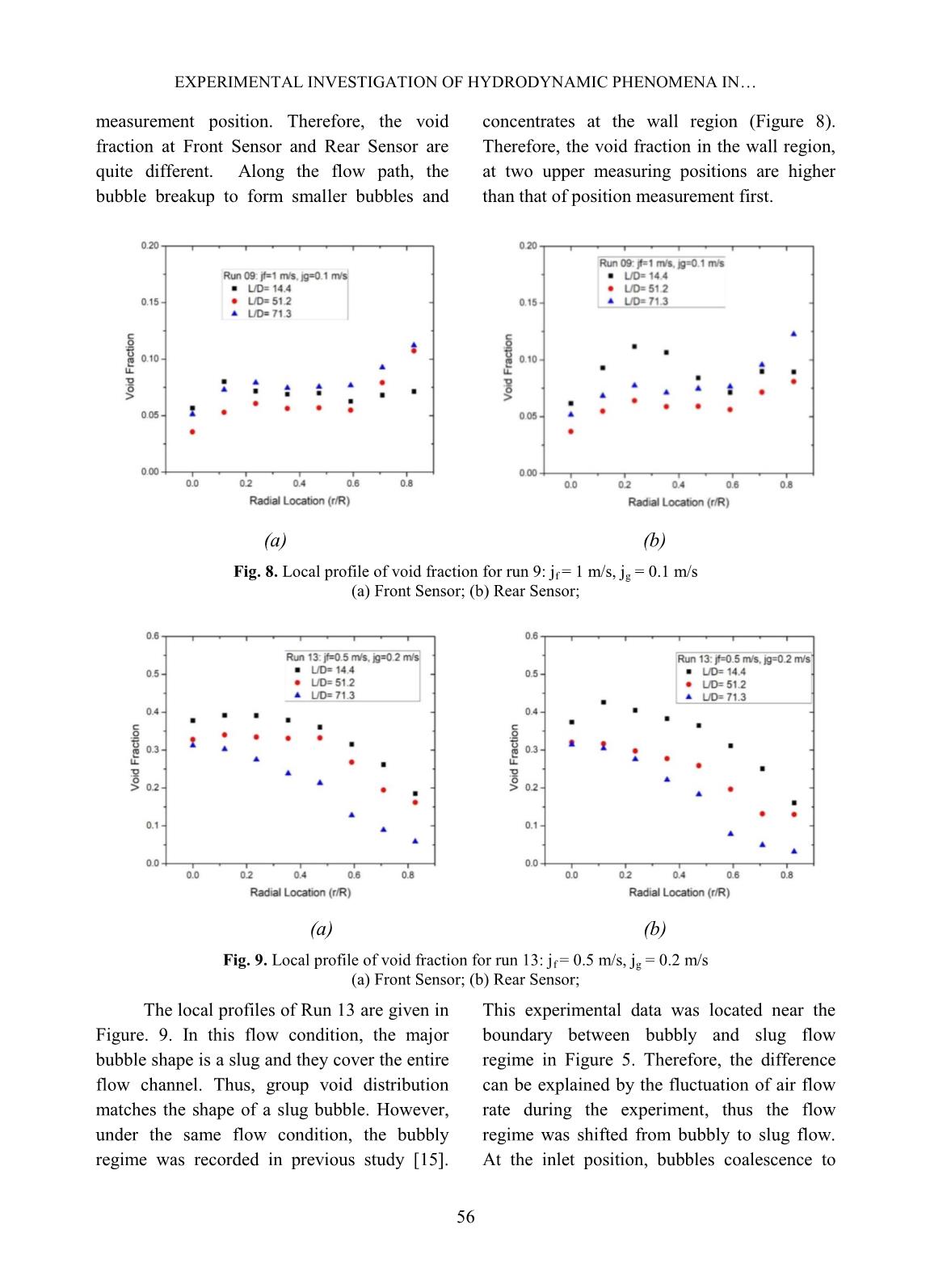

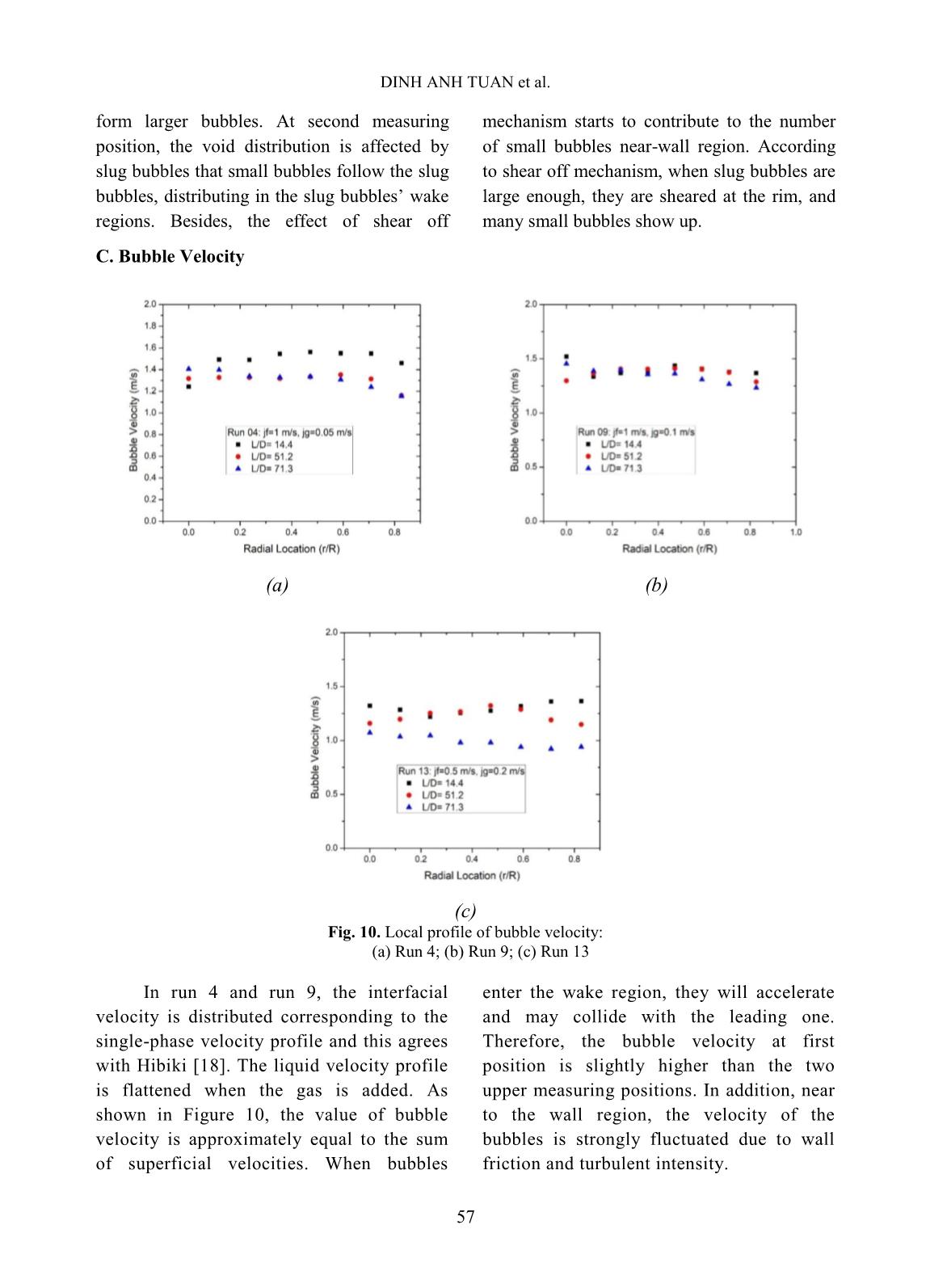

t of Signal TransRectangle & Filtering. This process is based on the algorithms of Signal Reading & Normalization Make Cut-off Levels Signal TransRectangle & Filtering Bubble Statics & Display DINH ANH TUAN et al. 53 Yun [12] and Euh [13]. Finally, the two-phase flow parameters are calculated in the part of Bubble Statics. From the square wave signal, the number of bubbles that hit the sensor can be measured by counting the number of pulses in the signal. The interfacial velocity of each interface can be obtained by using the distance to the different tips of the two-sensor probe and the time delay between the upstream and downstream signals. The parameters of the two-phase flow have been calculated as below [14]. - The time-averaged void fraction: The time-averaged void fraction is a function of the total sampling time - Ω, and the accumulated pulse widths of the upstream sensor during the sampling period. Thus, this time-averaged void fraction is simply the accumulated time the sensor is exposed to the gas phase divided by the total sampling time of the sensor. ̅ ∑ Where, Nt is the number of bubbles that strike the sensor; (tTF – tTR)j is the time that the sensor is exposed to the gas phase. - The time-averaged interfacial velocity: The interfacial velocity can be computed by taking into account the span among the tips of the front and rear sensor and the time difference between the front and rear signals. Thus, the time-averaged interfacial velocity is given as: | ⃗ | ∑ Where Δs is the distance between the front and rear sensor; tRR – tTR is the relative time between the bubble striking the front and rear sensor. IV. PRELIMINARY RESULTS AND DISCUSSION Experiment data was collected at 8 radial measurement points with each point distance of 1.5 mm along three axial positions (L/D = 14.4, L/D = 51.2, L/D = 71.3). All the flow conditions are summarized in Table I. Table I. Experimental flow condition Parameter Run 1-5 Run 6 -10 Run 11-13 Run 14-16 Run 17-19 Run 20-22 Run 23-25 Superficial gas velocity, jg [m/s] 0.05 0.10 0.20 0.30 0.50 0.80 1.00 Superficial water velocity, jf [m/s] 0.2 0.3 0.5 1.0 1.5 0.2 0.3 0.5 1.0 1.5 0.2 0.3 0.5 0.2 0.3 0.5 0.2 0.3 0.5 0.2 0.3 0.5 0.2 0.3 0.5 (1) (2) EXPERIMENTAL INVESTIGATION OF HYDRODYNAMIC PHENOMENA IN 54 Experiments carried out are represented in the flow regime map shown in figure 5 [15]. According to the flow map it can be seen that, when studying measurement of two-phase flow parameters, the authors measured with wider ranges based on the liquid and gas superficial velocities. However, it is still not possible to cover the entire. Therefore, the experimental system built at VINATOM with the measurement range shown in Figure 5 is expected to contribute to the missing experimental data on the flow regime map. Fig. 5. Test conditions on flow regime map A. Signal processing verification In order to ensure the quality of conductivity probe and the signal processing, the imaging technique is applied using the high- speed camera with xenon lamp for observing and recording the time of bubbles passed through the conductivity probe [16,17]. An independent small-scale experimental system was built. Test Section is a shape square acrylic box with a size of 2 × 2 cm 2 and a length of 40 cm. A small steel tube is used to generate a single bubble with a diameter of 2 to 5 mm. It is possible to determine the velocity of each bubble through the image processing software developed by the research team of Hanoi University of Science and Technology. Figure 6 presents the results of the comparison of the velocity measured by the imaging technique and conductivity probe. The difference between the two measurement techniques is within ± 15%. This result is good and suitable for use in the two-phase flow experiment. B. Local time-averaged void fraction In order to present better local parameter distribution and transport characteristics, the results of bubbly flow test condition Run 4 is selected. The time- averaged local void fraction and bubble velocity profiles at all three axial locations are given in Figure 7. Each row from top to bottom represents the result at L/D = 14.4, 51.2 and 71.3, respectively. DINH ANH TUAN et al. 55 Fig. 6. Comparison of bubble velocity obtained by Imaging Technique and Conductivity Probe (a) (b) Fig. 7. Local profile of void fraction for run 4: jf = 1 m/s, jg = 0.05 m/s (a) Front Sensor; (b) Rear Sensor In Run 4, the void distribution experiences a change process of transition (flat) (L/D = 14.4) – wall peak (L/D = 51.2 and 71.3). This reason is explained by the bubble breakup mechanism. At inlet position (L/D = 14.4), wake entrainment mechanism is dominant, small bubbles coalescence to larger bubble, and drive bubbles toward pipe center. Along the flow path, the liquid velocity is high, and bubbles will be break up to smaller bubbles due to the turbulent effect and forced toward the wall by lift force, resulting in the wall peak void distribution. This bubble interaction mechanism also results in small amount change of void fraction at two upper axial positions. This phenomenon matches the measurement result in the work of Dang [5]. When the flow rate of gas is higher in run 9, the bubbles are fluctuated at the first EXPERIMENTAL INVESTIGATION OF HYDRODYNAMIC PHENOMENA IN 56 measurement position. Therefore, the void fraction at Front Sensor and Rear Sensor are quite different. Along the flow path, the bubble breakup to form smaller bubbles and concentrates at the wall region (Figure 8). Therefore, the void fraction in the wall region, at two upper measuring positions are higher than that of position measurement first. (a) (b) Fig. 8. Local profile of void fraction for run 9: jf = 1 m/s, jg = 0.1 m/s (a) Front Sensor; (b) Rear Sensor; (a) (b) Fig. 9. Local profile of void fraction for run 13: jf = 0.5 m/s, jg = 0.2 m/s (a) Front Sensor; (b) Rear Sensor; The local profiles of Run 13 are given in Figure. 9. In this flow condition, the major bubble shape is a slug and they cover the entire flow channel. Thus, group void distribution matches the shape of a slug bubble. However, under the same flow condition, the bubbly regime was recorded in previous study [15]. This experimental data was located near the boundary between bubbly and slug flow regime in Figure 5. Therefore, the difference can be explained by the fluctuation of air flow rate during the experiment, thus the flow regime was shifted from bubbly to slug flow. At the inlet position, bubbles coalescence to DINH ANH TUAN et al. 57 form larger bubbles. At second measuring position, the void distribution is affected by slug bubbles that small bubbles follow the slug bubbles, distributing in the slug bubbles’ wake regions. Besides, the effect of shear off mechanism starts to contribute to the number of small bubbles near-wall region. According to shear off mechanism, when slug bubbles are large enough, they are sheared at the rim, and many small bubbles show up. C. Bubble Velocity (a) (b) (c) Fig. 10. Local profile of bubble velocity: (a) Run 4; (b) Run 9; (c) Run 13 In run 4 and run 9, the interfacial velocity is distributed corresponding to the single-phase velocity profile and this agrees with Hibiki [18]. The liquid velocity profile is flattened when the gas is added. As shown in Figure 10, the value of bubble velocity is approximately equal to the sum of superficial velocities. When bubbles enter the wake region, they will accelerate and may collide with the leading one. Therefore, the bubble velocity at first position is slightly higher than the two upper measuring positions. In addition, near to the wall region, the velocity of the bubbles is strongly fluctuated due to wall friction and turbulent intensity. EXPERIMENTAL INVESTIGATION OF HYDRODYNAMIC PHENOMENA IN 58 In Run 13, the channel-averaged velocity at the higher measuring positions are gradually decreased and are distributed almost uniformly in the radius. This phenomenon occurs in the case of low water superficial velocity, and drag force is domination. As the bubble grows, the bubble is normally accelerated by the effect of buoyancy force. However, due to the effect of drag force, velocity in run 13 is suitable. V. CONCLUSIONS The experimental investigation on local interfacial parameters for vertical upward air- water two-phase flow was performed in this study. Two-sensor conductivity probe was used for the measurement of 25 flow conditions that covers from bubbly flow to slug flow. The local parameters included are a time-averaged void fraction and bubble interfacial velocity. The data acquisition frequency of 10 kHz and the sampling time of 60 s were applied. From the local experimental results, the profiles of void fraction and interfacial velocity along the axial and radial of the flow channel were discussed in detail. The bubble interaction mechanisms caused the differences in local parameter distribution. For high liquid superficial velocity (jf), the effect of buoyancy force is dominant, and bubble break up phenomena is observed. On the contrary, for low liquid superficial velocity (jf), the effect of drag force is dominant and bubble interaction mechanism will change from bubble break up to bubble coalescence. When changing the flow conditions, the void fraction distribution changes from wall peaking at Run 4 and Run 9 to center peak at Run 13. The reason might be due to the uncertainties in the measured results that need to be carefully considered and reduced in future works. In conclusion, the test facility, the experimental methods, and the preliminary experimental results obtained in this study can be helpful to study and comprehend the fundamental two-phase flow phenomena. For practical application in nuclear reactor safety, they are envisaged to be further improved and applied to verification and validation of calculation methods and codes, e.g., CFD codes, in modeling of two-phase flow. NOMENCLATURE D – pipe diameter g – acceleration of gravity L – length lchord – chord length N – number of bubble p – pressure t – time tdelay – delay time u – velocity V – Volume Greek Symbols α – void fraction µ – viscosity ρ – density σ – deviation standard Ω – total sampling time Subscripts b – bubble f – liquid g – gas ACKNOWLEDGEMENT This work was performed at Institute of Nuclear Science and Technology, Vietnam Atomic Energy Institute under the project “Construction of Thermal-hydraulic Experiment and Investigation of Hydrodynamic Phenomena of Two-phase Flow”, grant code DTCB.17/16/VKHKTHN. The authors would like to thank Ministry of Science and Technology for their support on this project. REFERENCES [1]. L.S. Tong and Y.S. Tang., Boiling Heat Transfer And Two-Phase Flow (Series in DINH ANH TUAN et al. 59 Chemical and Mechanical Engineering), CRC Press (book), 1997. [2]. L.G. Neal and S.G. Bankoff., A high resolution resistivity probe for determination of local void properties in gas-liquid flow. AIChEJ (9) 490-494, 1963. [3]. M. Walter., Study on interfacial area transport in vertical bubbly flows, Ingenieur Thesis, Korea Atomic Energy Research Institute, Korea, 2008. [4]. A. Manera, B. Ozar, S. Paranjape, M. Ishii, H.- M. Prasser., Comparison between wire-mesh sensors and conductive needle-probes for measurements of two-phase flow parameters, Nuclear Engineering and Design (239) 1718– 1724, 2009. [5]. Z. Dang, G. Wang, P. Ju, X. Yang, R. Bean, M. Ishii, S. Bajorek, M. Bernard., Experimental study of interfacial characteristics of vertical upward air-water two-phase flow in 25.4 mm ID round pipe. International Journal of Heat and Mass Transfer (108) 1825–1838, 2017. [6]. K. Sekoguchi, H. Fukui, M. Tsutsui and K. Nishikawa., Investigation into the statistical characteristics of bubbles in two-phase flow (2nd Report, Application and establishment of electrical resistivity probe method), Bull. JSME (18) 397-404, 1975. [7]. M.S. Hoffer and W. Resnick., A modified electro resistivity probe technique for steady- and unsteady-state measurements in fine dispersions – I. Hardware and practical aspects, Chem. Engng. Sci. (30) 473-480, 1975. [8]. J.M. Burgess and P.H. Calderbank., The measurement of bubble parameters in two- phase dispersions-I. The development of an improved probe techniques, Chem. Engng Sci. (30) 743-750, 1975. [9]. M. Behnia, S.J., Gillespie., Void fraction measurement by a computerized double-point resistivity probe. Flow. Meas. Instrum. (2) 243-247, 1991. [10]. W.H. Leung, S.T. Revankar, Y. Ishii and M. Ishii., Axial development of interfacial area and void concentration profiles measured by double-sensor probe method, Int. J. Heat Mass Transfer (38) 445-453, 1995. [11]. X. Zhao, G. Lucas, and S. Pradhan., Signal Processing method in using four-sensor probe for measuring the velocity vector of air-liquid two phase flow. Journal of the Japanese Society of Experimental Mechanics (JSEM) (9) 19-24, 2009. [12]. B.J. Yun, K.H. Kim, G.C. Park, C.H. Chung,, A study on the Measurement of Local Void Fraction. Journal of the Korean Nuclear Society 24(2) 168-177, 1992. [13]. D.J. Euh, B.J. Yun, C.H. Song, T.S. Kwon, M.K. Chung, U.C. Lee., Development of the five-sensor conductivity probe method for the measurement of the interfacial are concentration, Nuclear Engineering and Design (205) 35-51, 2001. [14]. I. Kataoka and A. Serizawa., Averaged bubble diameter and interfacial area in bubbly flow, Proc. 5th Two-phase Symp. Japan, Kobe, Japan, 28-29 November 77-80, 1984. [15]. Y. Taitel, D. Bornea and A. E. Dukler., Modelling Flow Pattern Transitions for Steady Upward Gas-Liquid Flow in Vertical Tubes, AlChE Journal (Vol. 26, No. 3) 345–354, 1980. [16]. M. Ishii and S. Kim., Micro four-sensor probe measurement of interfacial area transport for bubbly flow in round pipes. Nuclear Engineering and Design 205 123-131, 2001. [17]. M. McCreary., Design and Testing Conductivity Probes for the Measurement of Two-Phase Flow Parameters. MS Thesis, Oregon State University, US, 2001. [18]. T. Hibiki, M. Ishii, Z. Xiao., Axial interfacial area transport of vertical bubbly flows, International Journal of Heat and Mass Transfer (44) 1869–1888, 2001.

File đính kèm:

experimental_investigation_of_hydrodynamic_phenomena_in_vert.pdf

experimental_investigation_of_hydrodynamic_phenomena_in_vert.pdf