Evaluation of slip ratio correlations in two-phase flow

Critical flow is one of the essential parameters in LOCA accident analysis in which

pressure difference is very high. Void fraction (α), in another term, slip ratio, s, is the key parameter

that could affect critical flow prediction. Henry-Fauske (HF) model is the model for critical flow

calculation existing in current computer codes such as MARS, RELAP, TRACE. However, the

limitation of this model is slip ratio s=1. By modified the slip ratio correlation, the paper focuses on

evaluating the HF model. Among the chosen correlations for slip ratio, Smith correlation is the best

option for this purpose. The results in our paper showed that while the original Smith correlation with

k=0.4 is suggested for horizontal tests, the modified one with k=0.2 could be applied for vertical tests.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tóm tắt nội dung tài liệu: Evaluation of slip ratio correlations in two-phase flow

epends on the phase velocity ratio,

slip ratio in the general form [8], [9] as a

function of quality (x), density (ρ), and

viscosity (µ):

(

)

(

)

(

)

In reality, only several types of

reactors for gas/liquid exist. Moreover, one

could be noted that the contribution of the

viscosity component as shown in Table I,

(

)

, is less dominant. Therefore, this

parameter could be negligible in the void

fraction form. Void fraction correlations then

could be reduced as follows:

(

)

(

)

or

(

) (

)

Where the slip ratio, s, is determined

as follows:

(

)

(

)

Select the void fraction correlations

having the form in Eq. (7), the author has

compared them with the available experimental

data (Table I).

Void fraction correlations related to slip

ratio are listed in Table II.

Where: Re and We are Reynolds and

Weber numbers, D is the equivalent diameter.

APRM, APA and M parameters are determined as

followings:

{

},

(

)

,

, (

)

(

)

,

,

, a

1+log(

) log(

) ,

, σ is surface

tension.

Table I. References related void fraction data measurement.

Reference Diameter[mm] Working fluid Geometry Pressure [psi]

Marchettere[11] 127 Steam-Water Rectangular, vertical 114 - 600

Cook [12] 127 Steam-Water Rectangular, vertical 114 - 600

Haywood [13] 12.7-38.1 Steam-Water Pipe, horizontal 250 - 2100

THANH TRAM TRAN, HYUN-SIK PARK

25

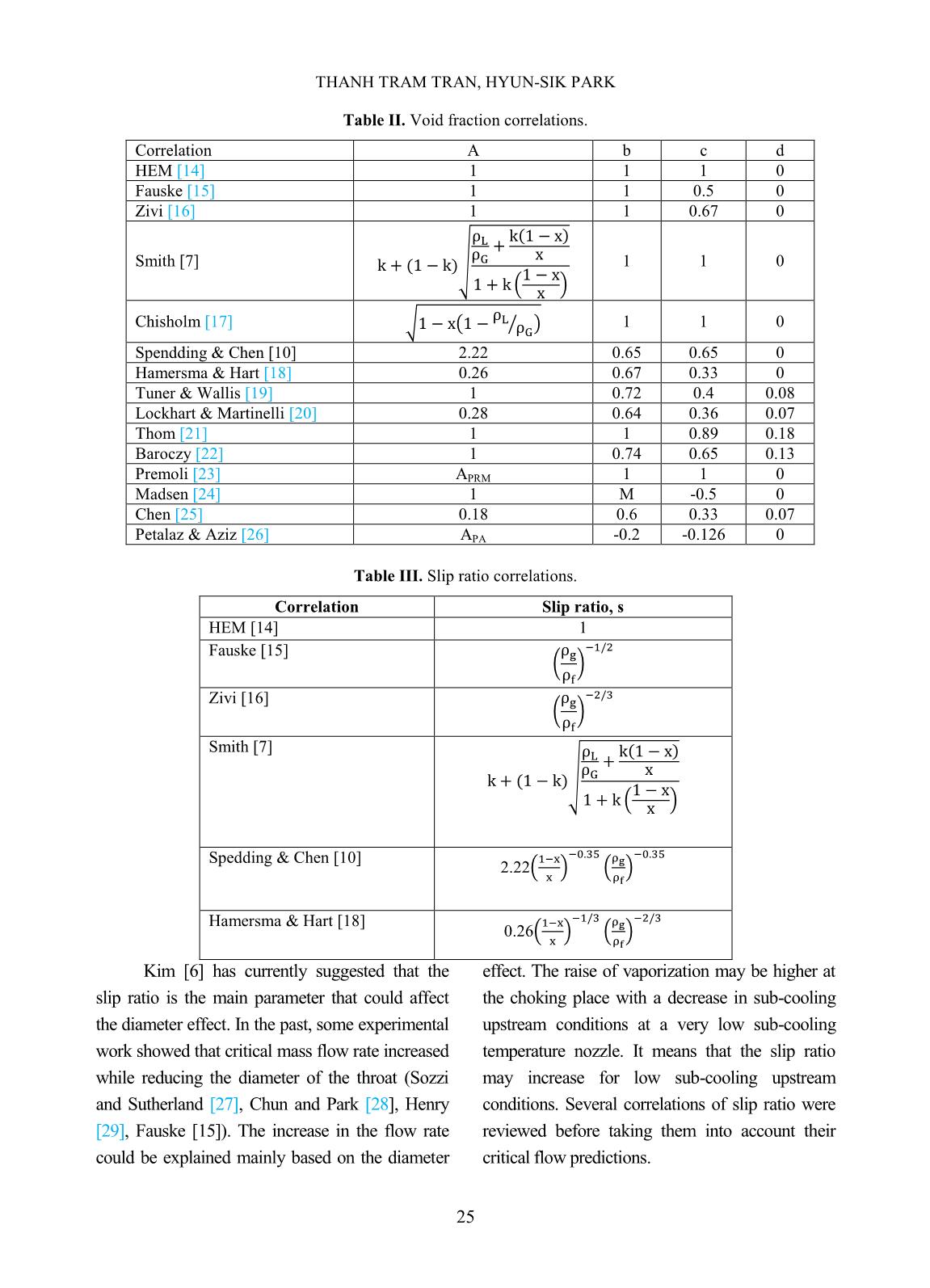

Table II. Void fraction correlations.

Correlation A b c d

HEM [14] 1 1 1 0

Fauske [15] 1 1 0.5 0

Zivi [16] 1 1 0.67 0

Smith [7] √

(

)

1 1 0

Chisholm [17] √ (

⁄ )

1 1 0

Spendding & Chen [10] 2.22 0.65 0.65 0

Hamersma & Hart [18] 0.26 0.67 0.33 0

Tuner & Wallis [19] 1 0.72 0.4 0.08

Lockhart & Martinelli [20] 0.28 0.64 0.36 0.07

Thom [21] 1 1 0.89 0.18

Baroczy [22] 1 0.74 0.65 0.13

Premoli [23] APRM 1 1 0

Madsen [24] 1 M -0.5 0

Chen [25] 0.18 0.6 0.33 0.07

Petalaz & Aziz [26] APA -0.2 -0.126 0

Table III. Slip ratio correlations.

Kim [6] has currently suggested that the

slip ratio is the main parameter that could affect

the diameter effect. In the past, some experimental

work showed that critical mass flow rate increased

while reducing the diameter of the throat (Sozzi

and Sutherland [27], Chun and Park [28], Henry

[29], Fauske [15]). The increase in the flow rate

could be explained mainly based on the diameter

effect. The raise of vaporization may be higher at

the choking place with a decrease in sub-cooling

upstream conditions at a very low sub-cooling

temperature nozzle. It means that the slip ratio

may increase for low sub-cooling upstream

conditions. Several correlations of slip ratio were

reviewed before taking them into account their

critical flow predictions.

Correlation Slip ratio, s

HEM [14] 1

Fauske [15]

(

)

Zivi [16]

(

)

Smith [7]

√

(

)

Spedding & Chen [10]

2.22(

)

(

)

Hamersma & Hart [18]

0.26(

)

(

)

EVALUATION OF SLIP RATIO CORRELATIONS IN TWO-PHASE FLOW

26

By comparing with the experimental

data, void fraction correlations listed in Table I

are evaluated. The six selected correlations are

rewritten in the slip ratio form, as shown in

Table III. Those slip ratio correlations will be

evaluated in more detail using different

pressures for both horizontal [11] and vertical

[12],[13] tests.

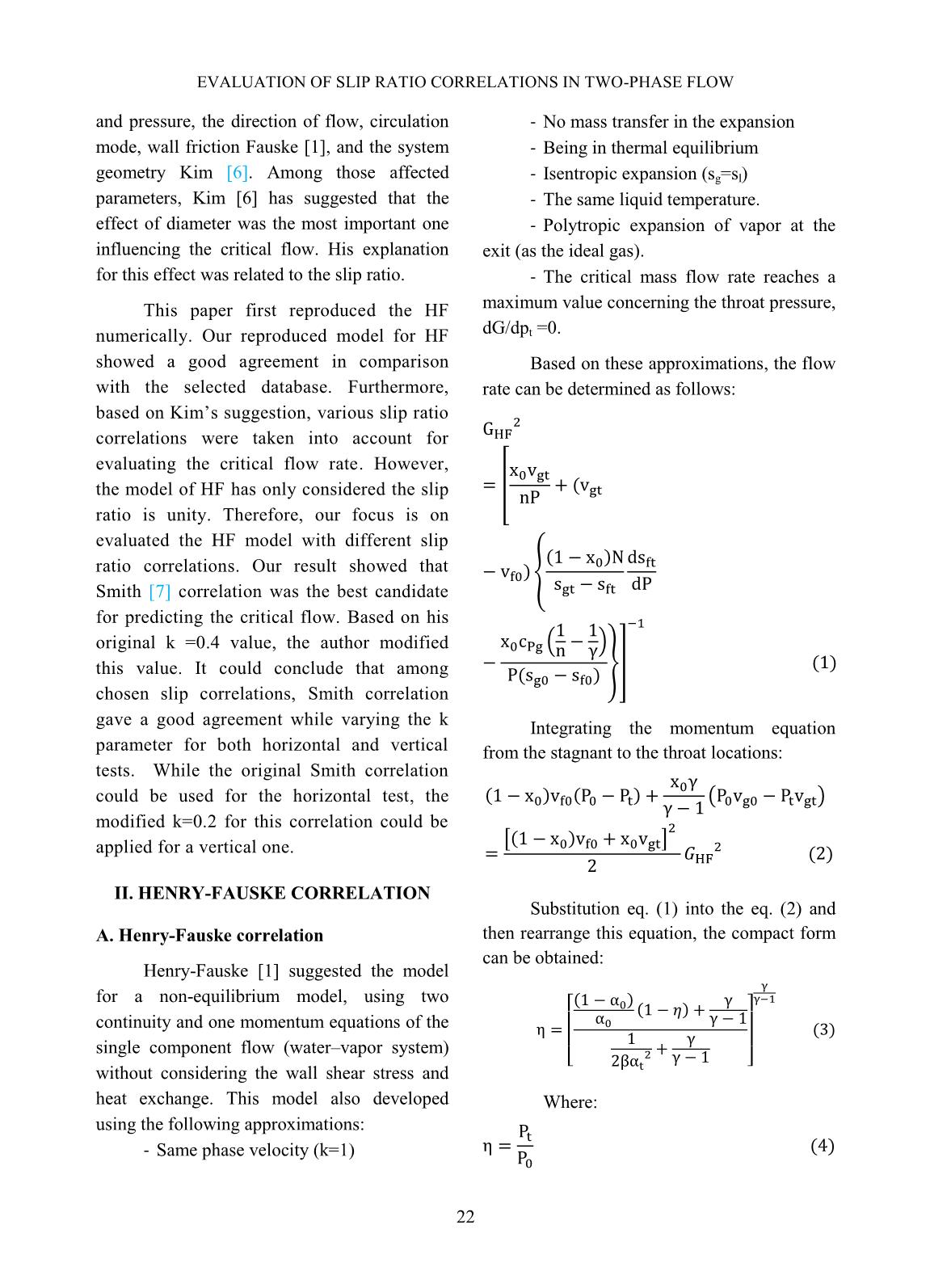

A. Evaluations using horizontal test data

Chosen correlations are compared with

Haywood data for a horizontal test in a high-

pressure range from 1.72 to 14.5 MPa, as

shown in Figs. 4, 5, and 6.

Even data changes in a high-pressure

range, the original Smith’s correlation remains

the best candidate. We can conclude that

Smith’s correlation with his recommended k =

0.4 gives the best predictions.

Fig. 4. Void fraction vs. quality in comparing with

the Haywood data at 4.14 MPa (600 psi) [13].

Fig. 5. Void fraction vs. quality in comparing with

the Haywood data at 8.62 MPa (1250 psi) [13].

Fig. 6. Void fraction vs. quality in comparing with

the Haywood data at 14.48 MPa (2100 psi) [13].

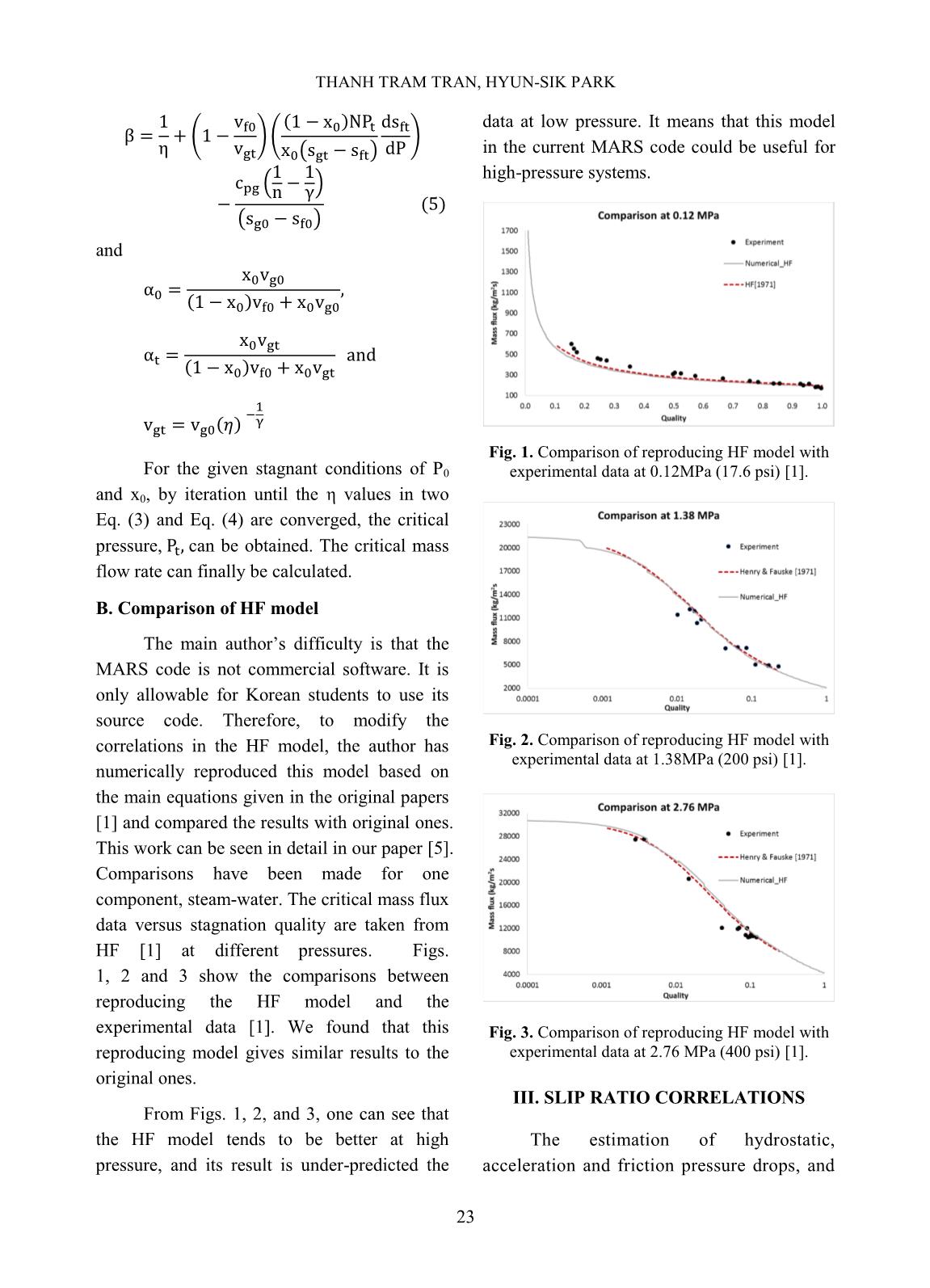

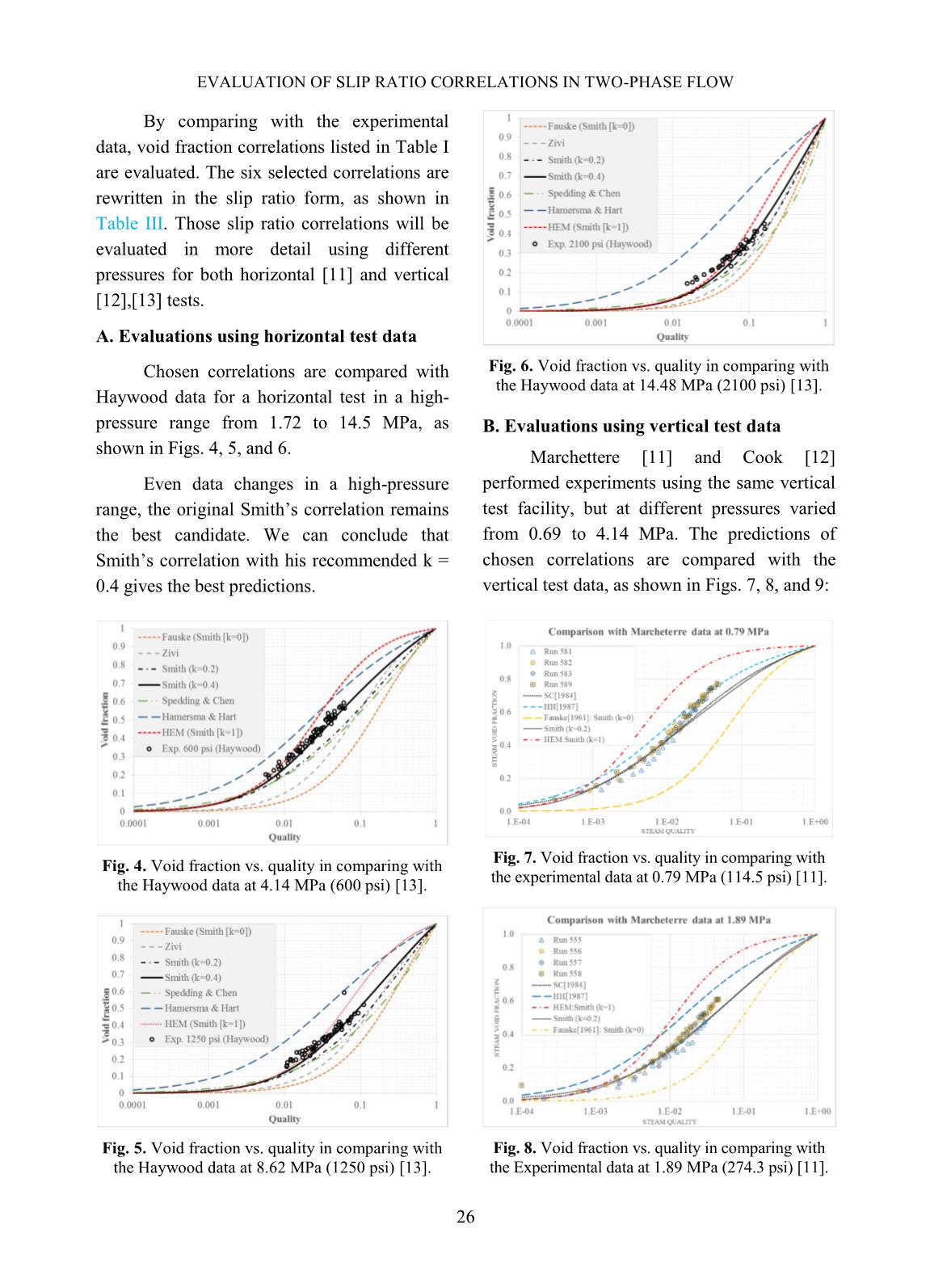

B. Evaluations using vertical test data

Marchettere [11] and Cook [12]

performed experiments using the same vertical

test facility, but at different pressures varied

from 0.69 to 4.14 MPa. The predictions of

chosen correlations are compared with the

vertical test data, as shown in Figs. 7, 8, and 9:

Fig. 7. Void fraction vs. quality in comparing with

the experimental data at 0.79 MPa (114.5 psi) [11].

Fig. 8. Void fraction vs. quality in comparing with

the Experimental data at 1.89 MPa (274.3 psi) [11].

THANH TRAM TRAN, HYUN-SIK PARK

27

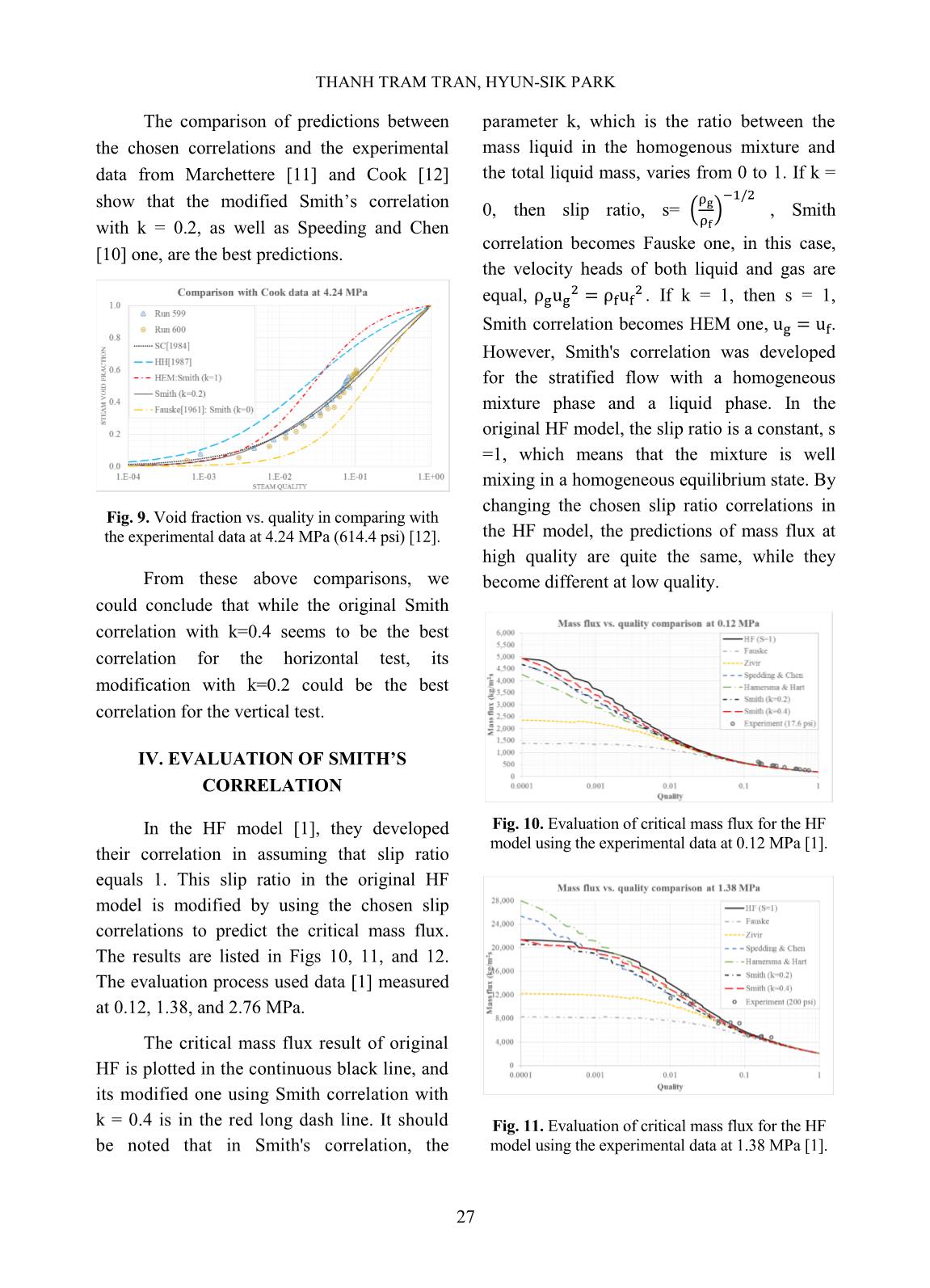

The comparison of predictions between

the chosen correlations and the experimental

data from Marchettere [11] and Cook [12]

show that the modified Smith’s correlation

with k = 0.2, as well as Speeding and Chen

[10] one, are the best predictions.

Fig. 9. Void fraction vs. quality in comparing with

the experimental data at 4.24 MPa (614.4 psi) [12].

From these above comparisons, we

could conclude that while the original Smith

correlation with k=0.4 seems to be the best

correlation for the horizontal test, its

modification with k=0.2 could be the best

correlation for the vertical test.

IV. EVALUATION OF SMITH’S

CORRELATION

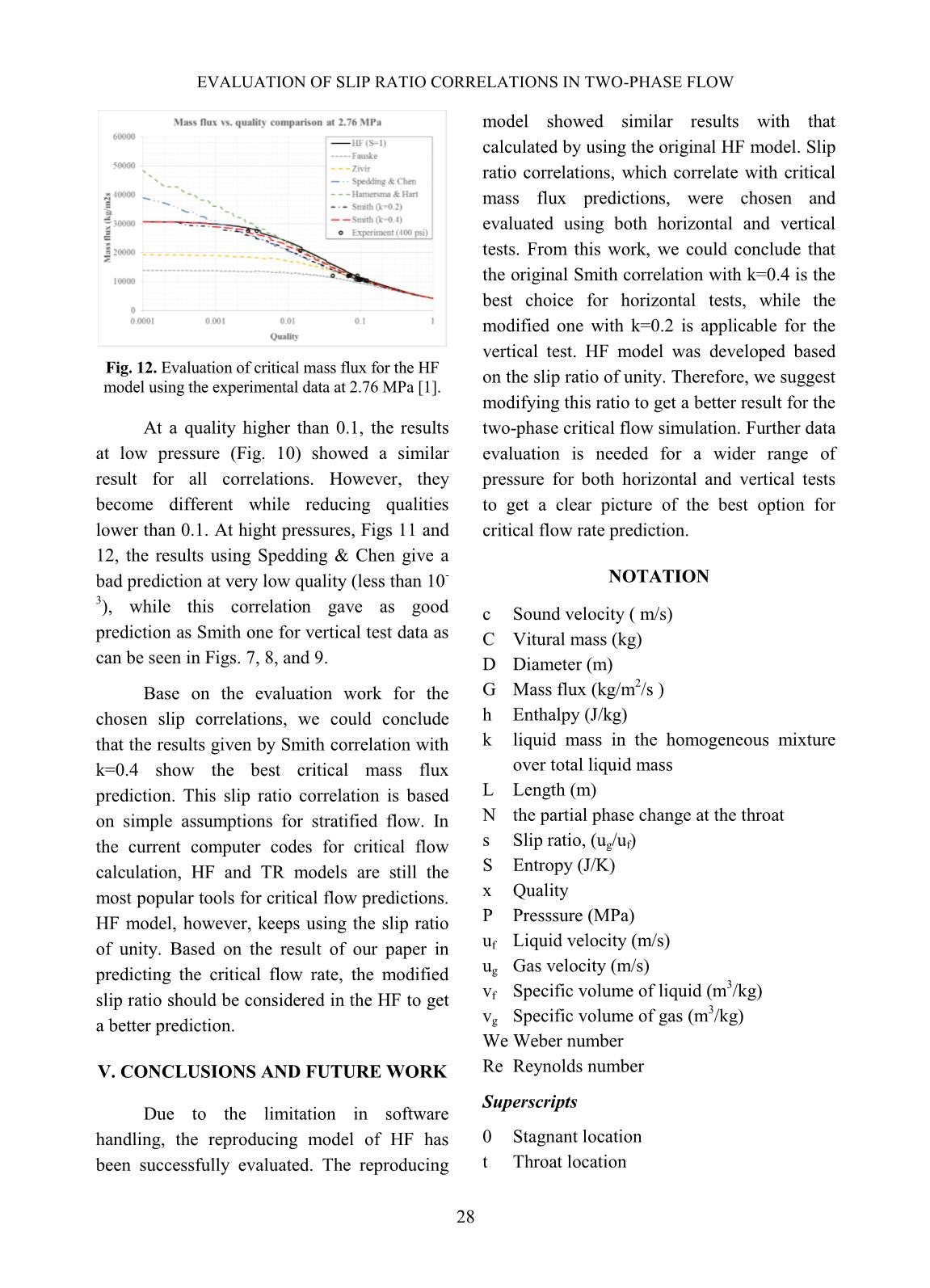

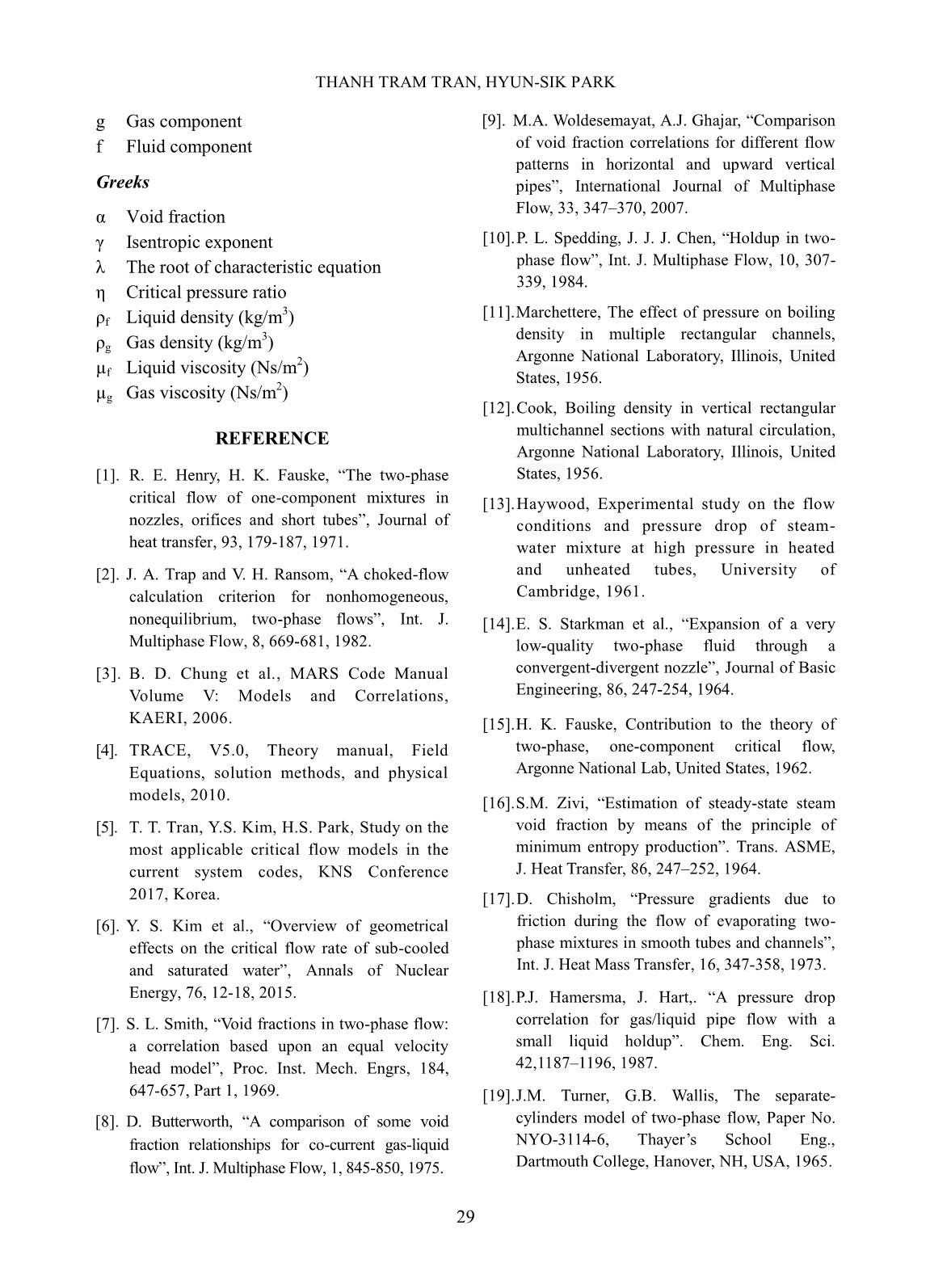

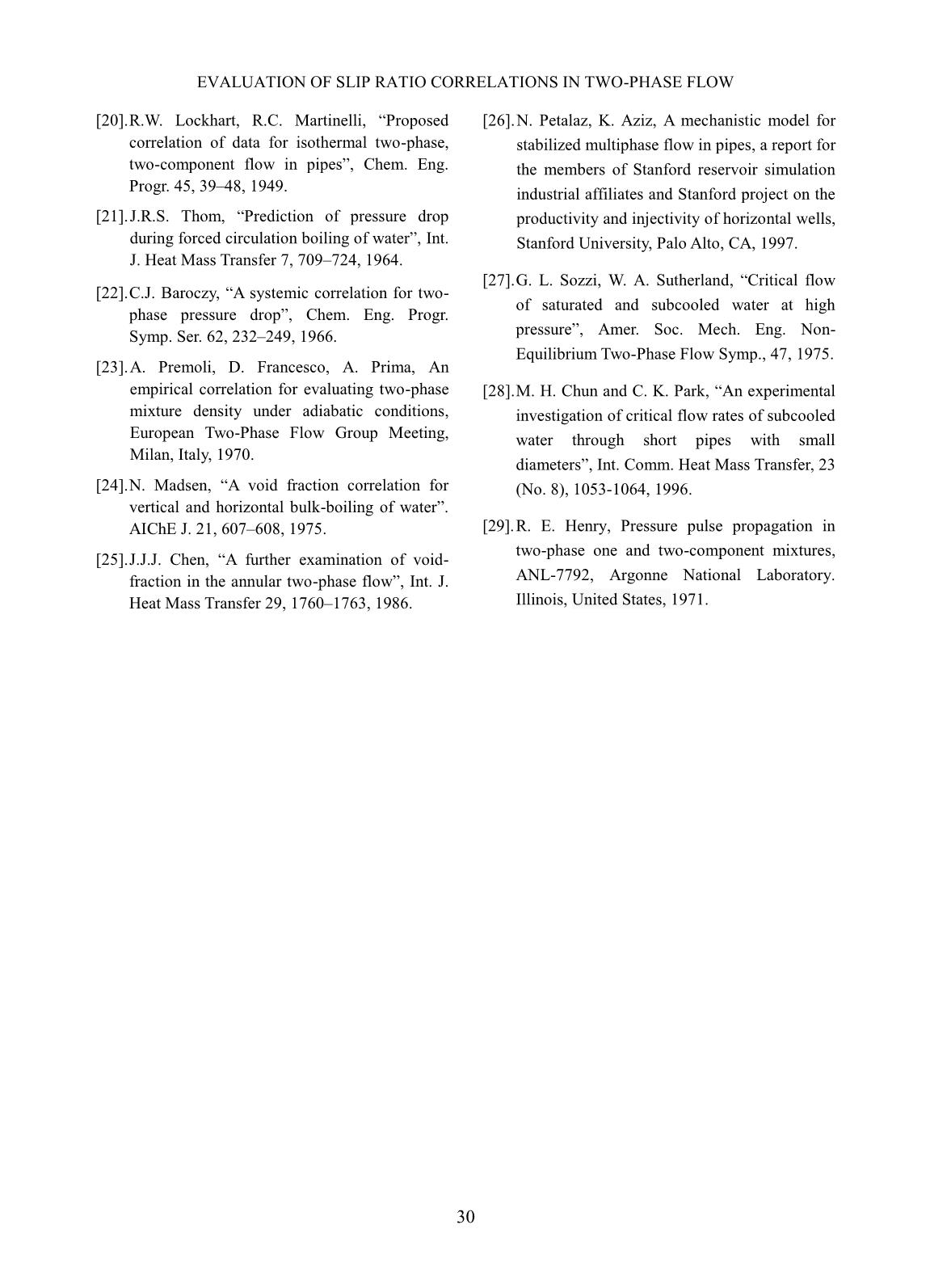

In the HF model [1], they developed

their correlation in assuming that slip ratio

equals 1. This slip ratio in the original HF

model is modified by using the chosen slip

correlations to predict the critical mass flux.

The results are listed in Figs 10, 11, and 12.

The evaluation process used data [1] measured

at 0.12, 1.38, and 2.76 MPa.

The critical mass flux result of original

HF is plotted in the continuous black line, and

its modified one using Smith correlation with

k = 0.4 is in the red long dash line. It should

be noted that in Smith's correlation, the

parameter k, which is the ratio between the

mass liquid in the homogenous mixture and

the total liquid mass, varies from 0 to 1. If k =

0, then slip ratio, s= (

)

, Smith

correlation becomes Fauske one, in this case,

the velocity heads of both liquid and gas are

equal,

. If k = 1, then s = 1,

Smith correlation becomes HEM one, .

However, Smith's correlation was developed

for the stratified flow with a homogeneous

mixture phase and a liquid phase. In the

original HF model, the slip ratio is a constant, s

=1, which means that the mixture is well

mixing in a homogeneous equilibrium state. By

changing the chosen slip ratio correlations in

the HF model, the predictions of mass flux at

high quality are quite the same, while they

become different at low quality.

Fig. 10. Evaluation of critical mass flux for the HF

model using the experimental data at 0.12 MPa [1].

Fig. 11. Evaluation of critical mass flux for the HF

model using the experimental data at 1.38 MPa [1].

EVALUATION OF SLIP RATIO CORRELATIONS IN TWO-PHASE FLOW

28

Fig. 12. Evaluation of critical mass flux for the HF

model using the experimental data at 2.76 MPa [1].

At a quality higher than 0.1, the results

at low pressure (Fig. 10) showed a similar

result for all correlations. However, they

become different while reducing qualities

lower than 0.1. At hight pressures, Figs 11 and

12, the results using Spedding & Chen give a

bad prediction at very low quality (less than 10

-

3

), while this correlation gave as good

prediction as Smith one for vertical test data as

can be seen in Figs. 7, 8, and 9.

Base on the evaluation work for the

chosen slip correlations, we could conclude

that the results given by Smith correlation with

k=0.4 show the best critical mass flux

prediction. This slip ratio correlation is based

on simple assumptions for stratified flow. In

the current computer codes for critical flow

calculation, HF and TR models are still the

most popular tools for critical flow predictions.

HF model, however, keeps using the slip ratio

of unity. Based on the result of our paper in

predicting the critical flow rate, the modified

slip ratio should be considered in the HF to get

a better prediction.

V. CONCLUSIONS AND FUTURE WORK

Due to the limitation in software

handling, the reproducing model of HF has

been successfully evaluated. The reproducing

model showed similar results with that

calculated by using the original HF model. Slip

ratio correlations, which correlate with critical

mass flux predictions, were chosen and

evaluated using both horizontal and vertical

tests. From this work, we could conclude that

the original Smith correlation with k=0.4 is the

best choice for horizontal tests, while the

modified one with k=0.2 is applicable for the

vertical test. HF model was developed based

on the slip ratio of unity. Therefore, we suggest

modifying this ratio to get a better result for the

two-phase critical flow simulation. Further data

evaluation is needed for a wider range of

pressure for both horizontal and vertical tests

to get a clear picture of the best option for

critical flow rate prediction.

NOTATION

c Sound velocity ( m/s)

C Vitural mass (kg)

D Diameter (m)

G Mass flux (kg/m

2

/s )

h Enthalpy (J/kg)

k liquid mass in the homogeneous mixture

over total liquid mass

L Length (m)

N the partial phase change at the throat

s Slip ratio, (ug/uf)

S Entropy (J/K)

x Quality

P Presssure (MPa)

uf Liquid velocity (m/s)

ug Gas velocity (m/s)

vf Specific volume of liquid (m

3

/kg)

vg Specific volume of gas (m

3

/kg)

We Weber number

Re Reynolds number

Superscripts

0 Stagnant location

t Throat location

THANH TRAM TRAN, HYUN-SIK PARK

29

g Gas component

f Fluid component

Greeks

α Void fraction

γ Isentropic exponent

λ The root of characteristic equation

η Critical pressure ratio

ρf Liquid density (kg/m

3

)

ρg Gas density (kg/m

3

)

µf Liquid viscosity (Ns/m

2

)

µg Gas viscosity (Ns/m

2

)

REFERENCE

[1]. R. E. Henry, H. K. Fauske, “The two-phase

critical flow of one-component mixtures in

nozzles, orifices and short tubes”, Journal of

heat transfer, 93, 179-187, 1971.

[2]. J. A. Trap and V. H. Ransom, “A choked-flow

calculation criterion for nonhomogeneous,

nonequilibrium, two-phase flows”, Int. J.

Multiphase Flow, 8, 669-681, 1982.

[3]. B. D. Chung et al., MARS Code Manual

Volume V: Models and Correlations,

KAERI, 2006.

[4]. TRACE, V5.0, Theory manual, Field

Equations, solution methods, and physical

models, 2010.

[5]. T. T. Tran, Y.S. Kim, H.S. Park, Study on the

most applicable critical flow models in the

current system codes, KNS Conference

2017, Korea.

[6]. Y. S. Kim et al., “Overview of geometrical

effects on the critical flow rate of sub-cooled

and saturated water”, Annals of Nuclear

Energy, 76, 12-18, 2015.

[7]. S. L. Smith, “Void fractions in two-phase flow:

a correlation based upon an equal velocity

head model”, Proc. Inst. Mech. Engrs, 184,

647-657, Part 1, 1969.

[8]. D. Butterworth, “A comparison of some void

fraction relationships for co-current gas-liquid

flow”, Int. J. Multiphase Flow, 1, 845-850, 1975.

[9]. M.A. Woldesemayat, A.J. Ghajar, “Comparison

of void fraction correlations for different flow

patterns in horizontal and upward vertical

pipes”, International Journal of Multiphase

Flow, 33, 347–370, 2007.

[10]. P. L. Spedding, J. J. J. Chen, “Holdup in two-

phase flow”, Int. J. Multiphase Flow, 10, 307-

339, 1984.

[11]. Marchettere, The effect of pressure on boiling

density in multiple rectangular channels,

Argonne National Laboratory, Illinois, United

States, 1956.

[12]. Cook, Boiling density in vertical rectangular

multichannel sections with natural circulation,

Argonne National Laboratory, Illinois, United

States, 1956.

[13]. Haywood, Experimental study on the flow

conditions and pressure drop of steam-

water mixture at high pressure in heated

and unheated tubes, University of

Cambridge, 1961.

[14]. E. S. Starkman et al., “Expansion of a very

low-quality two-phase fluid through a

convergent-divergent nozzle”, Journal of Basic

Engineering, 86, 247-254, 1964.

[15]. H. K. Fauske, Contribution to the theory of

two-phase, one-component critical flow,

Argonne National Lab, United States, 1962.

[16]. S.M. Zivi, “Estimation of steady-state steam

void fraction by means of the principle of

minimum entropy production”. Trans. ASME,

J. Heat Transfer, 86, 247–252, 1964.

[17]. D. Chisholm, “Pressure gradients due to

friction during the flow of evaporating two-

phase mixtures in smooth tubes and channels”,

Int. J. Heat Mass Transfer, 16, 347-358, 1973.

[18]. P.J. Hamersma, J. Hart,. “A pressure drop

correlation for gas/liquid pipe flow with a

small liquid holdup”. Chem. Eng. Sci.

42,1187–1196, 1987.

[19]. J.M. Turner, G.B. Wallis, The separate-

cylinders model of two-phase flow, Paper No.

NYO-3114-6, Thayer’s School Eng.,

Dartmouth College, Hanover, NH, USA, 1965.

EVALUATION OF SLIP RATIO CORRELATIONS IN TWO-PHASE FLOW

30

[20]. R.W. Lockhart, R.C. Martinelli, “Proposed

correlation of data for isothermal two-phase,

two-component flow in pipes”, Chem. Eng.

Progr. 45, 39–48, 1949.

[21]. J.R.S. Thom, “Prediction of pressure drop

during forced circulation boiling of water”, Int.

J. Heat Mass Transfer 7, 709–724, 1964.

[22]. C.J. Baroczy, “A systemic correlation for two-

phase pressure drop”, Chem. Eng. Progr.

Symp. Ser. 62, 232–249, 1966.

[23]. A. Premoli, D. Francesco, A. Prima, An

empirical correlation for evaluating two-phase

mixture density under adiabatic conditions,

European Two-Phase Flow Group Meeting,

Milan, Italy, 1970.

[24]. N. Madsen, “A void fraction correlation for

vertical and horizontal bulk-boiling of water”.

AIChE J. 21, 607–608, 1975.

[25]. J.J.J. Chen, “A further examination of void-

fraction in the annular two-phase flow”, Int. J.

Heat Mass Transfer 29, 1760–1763, 1986.

[26]. N. Petalaz, K. Aziz, A mechanistic model for

stabilized multiphase flow in pipes, a report for

the members of Stanford reservoir simulation

industrial affiliates and Stanford project on the

productivity and injectivity of horizontal wells,

Stanford University, Palo Alto, CA, 1997.

[27]. G. L. Sozzi, W. A. Sutherland, “Critical flow

of saturated and subcooled water at high

pressure”, Amer. Soc. Mech. Eng. Non-

Equilibrium Two-Phase Flow Symp., 47, 1975.

[28]. M. H. Chun and C. K. Park, “An experimental

investigation of critical flow rates of subcooled

water through short pipes with small

diameters”, Int. Comm. Heat Mass Transfer, 23

(No. 8), 1053-1064, 1996.

[29]. R. E. Henry, Pressure pulse propagation in

two-phase one and two-component mixtures,

ANL-7792, Argonne National Laboratory.

Illinois, United States, 1971.

File đính kèm:

evaluation_of_slip_ratio_correlations_in_two_phase_flow.pdf

evaluation_of_slip_ratio_correlations_in_two_phase_flow.pdf