Thermal distribution and reliability prediction for 3D networks-on-chip

As one of the most promising technologies to reduce footprint, power consumption and

wire latency, Three Dimensional Integrated Circuits (3D-ICs) is considered as the near future for

VLSI system. Combining with the Network-on-Chip infrastructure to obtain 3D Networks-onChip (3D-NoCs), the new on-chip communication paradigm brings several advantages. However,

thermal dissipation is one of the most critical challenges for 3D-ICs, where the heat cannot easily

transfer through several layers of silicon. Consequently, the high-temperature area also confronts

the reliability threat as the Mean Time to Failure (MTTF) decreases exponentially with the

operating temperature as in Black’s model. Apparently, 3D-NoCs and 3D ICs must tackle this

fundamental problem in order to be widely used. However, the thermal analyses usually require

complicated simulation and might cost an enormous execution time. As a closed-loop design flow,

designers may take several times to optimize their designs which significantly increase the thermal

analyzing time. Furthermore, reliability prediction also requires both completed design and

thermal prediction, and designer can use the result as a feedback for their optimization. As we can

observe two big gaps in the design flow, it is difficult to obtain both of them which put 3D-NoCs

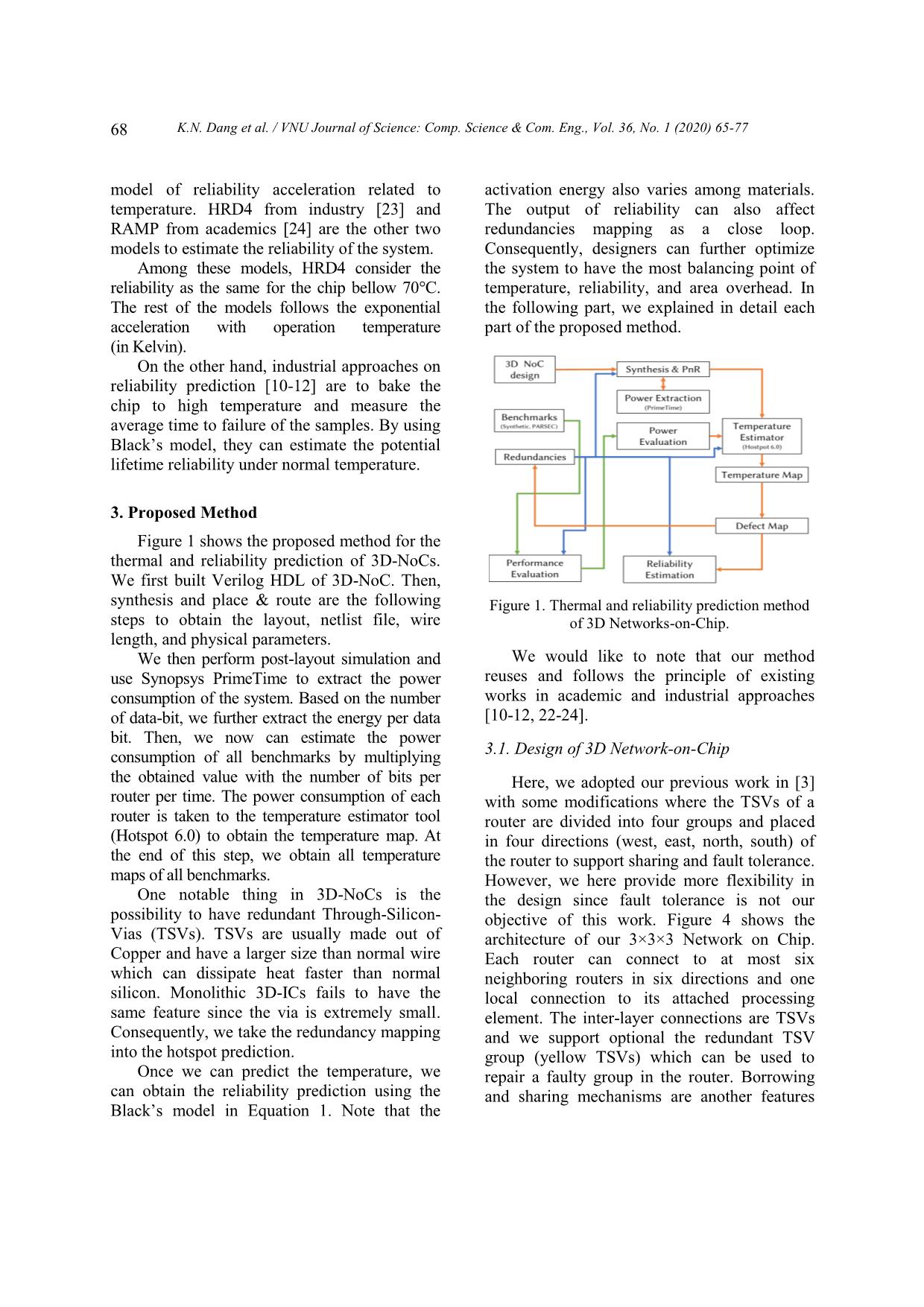

under thermal throttling and reliability threats. Therefore, in this work, we investigate the thermal

distribution and reliability prediction of 3D-NoCs. We first propose a new method to help simulate

the temperature (both steady and transient) using traffic values from realistic and synthetic

benchmarks and the power consumption from standard VLSI design flow. Then, based on the

proposed method, we further predict the relative reliability between different parts of the network.

Experimental results show that the method has an extremely fast execution time in comparison to

the acceleration lifetime test. Furthermore, we compare the thermal behavior and reliability

between Monolithic design and TSV (Through-Silicon-Via) based design. We also explore the

ability to implement the thermal via a mechanism to help reduce the operating temperature.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

Tóm tắt nội dung tài liệu: Thermal distribution and reliability prediction for 3D networks-on-chip

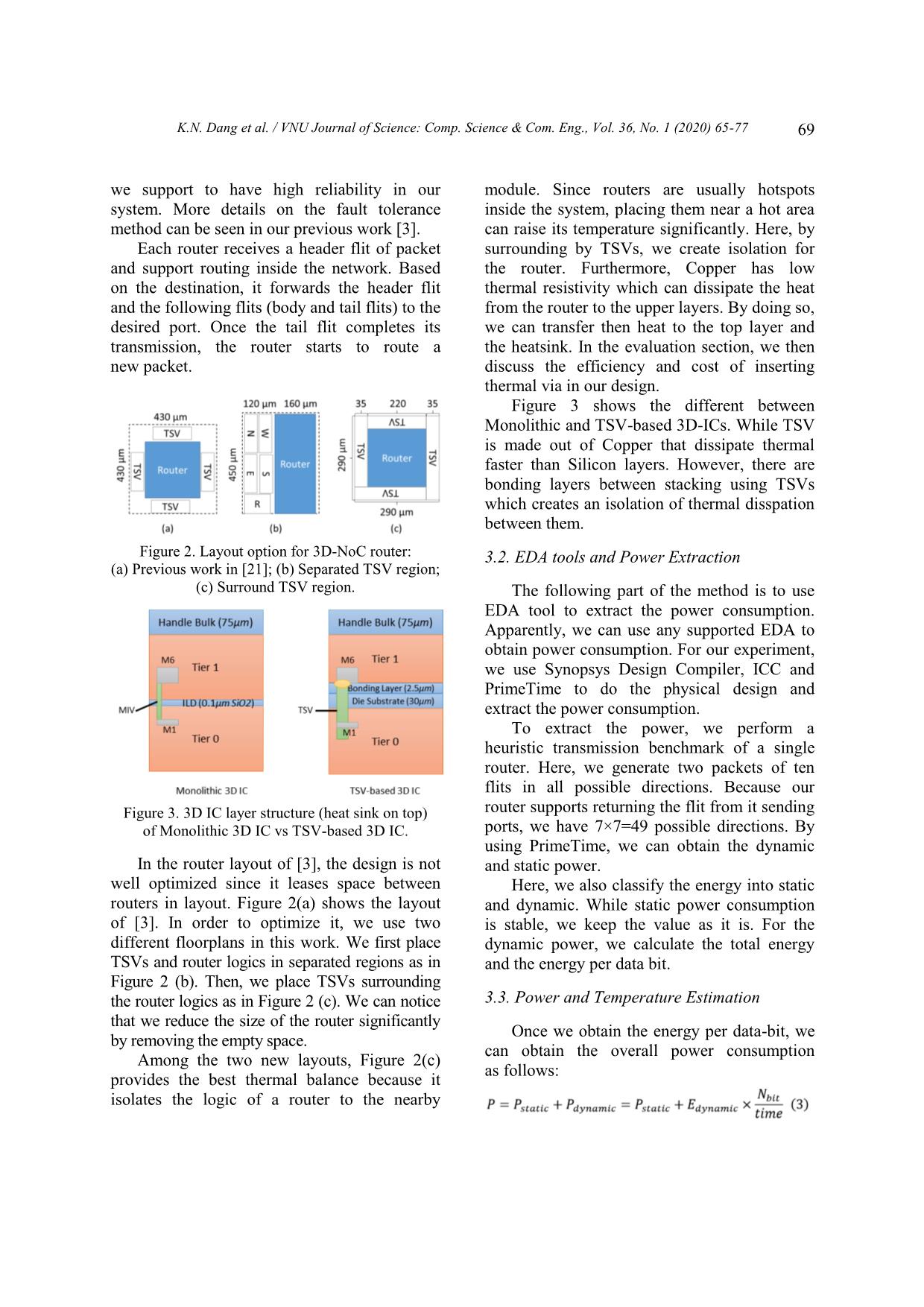

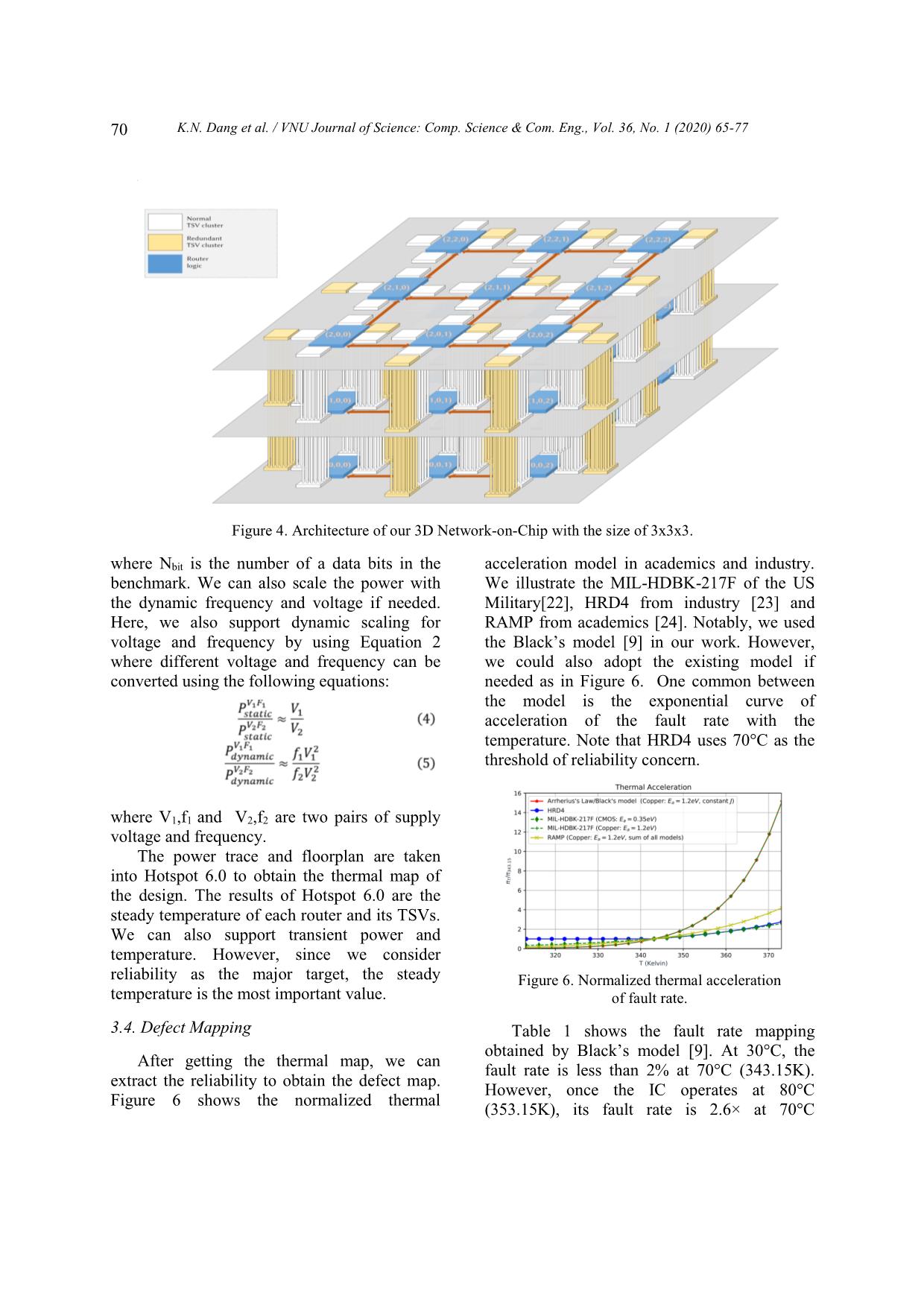

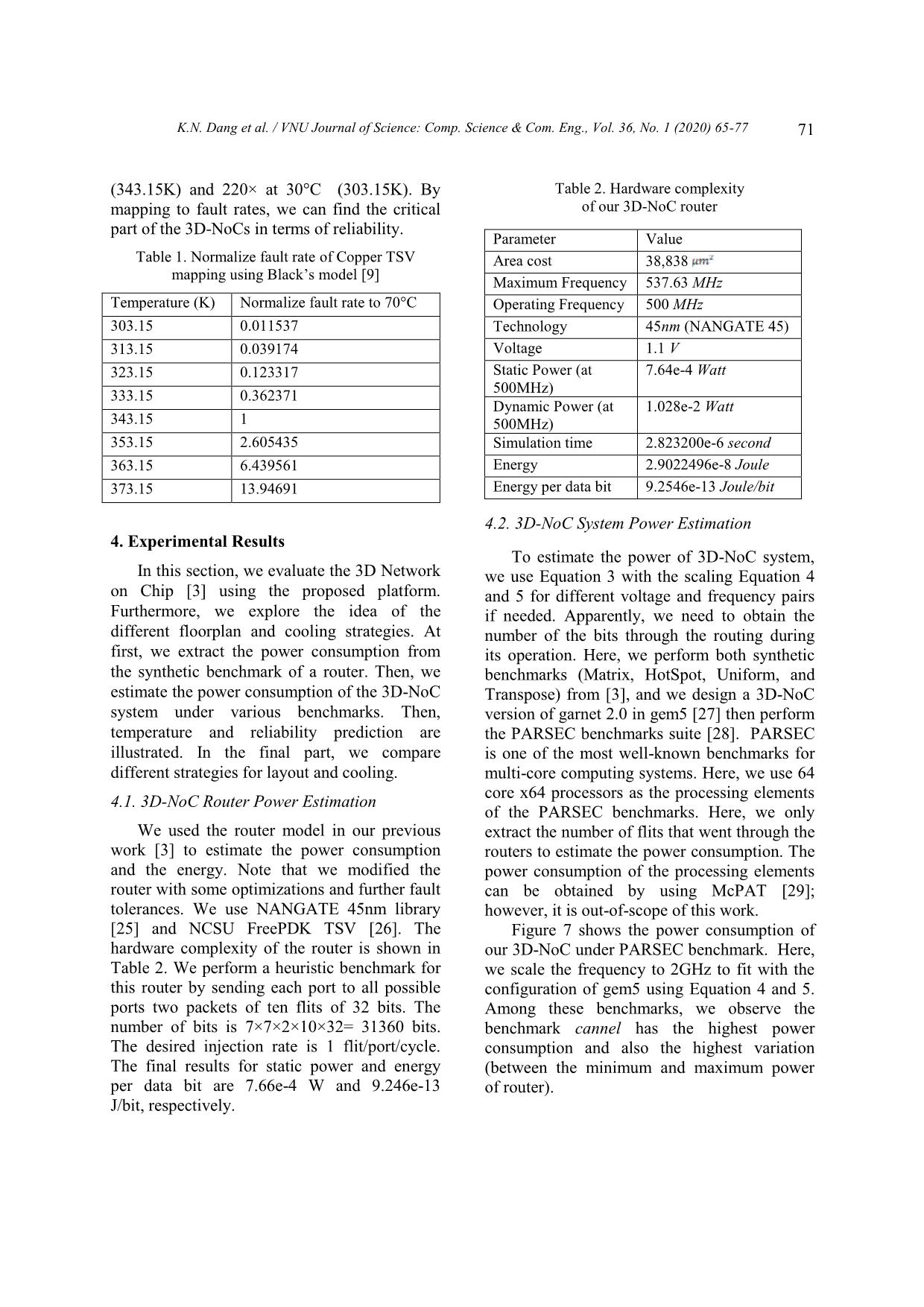

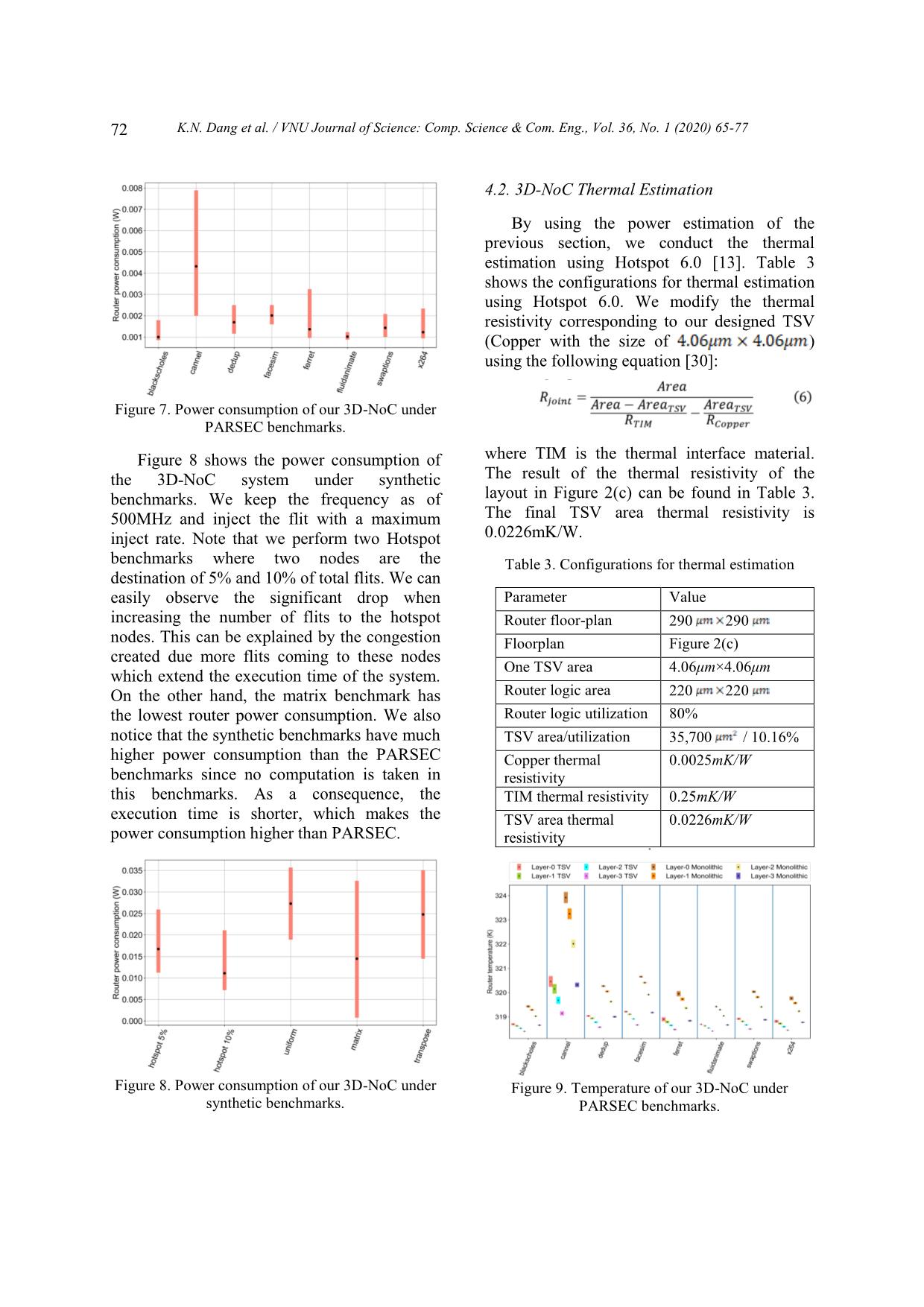

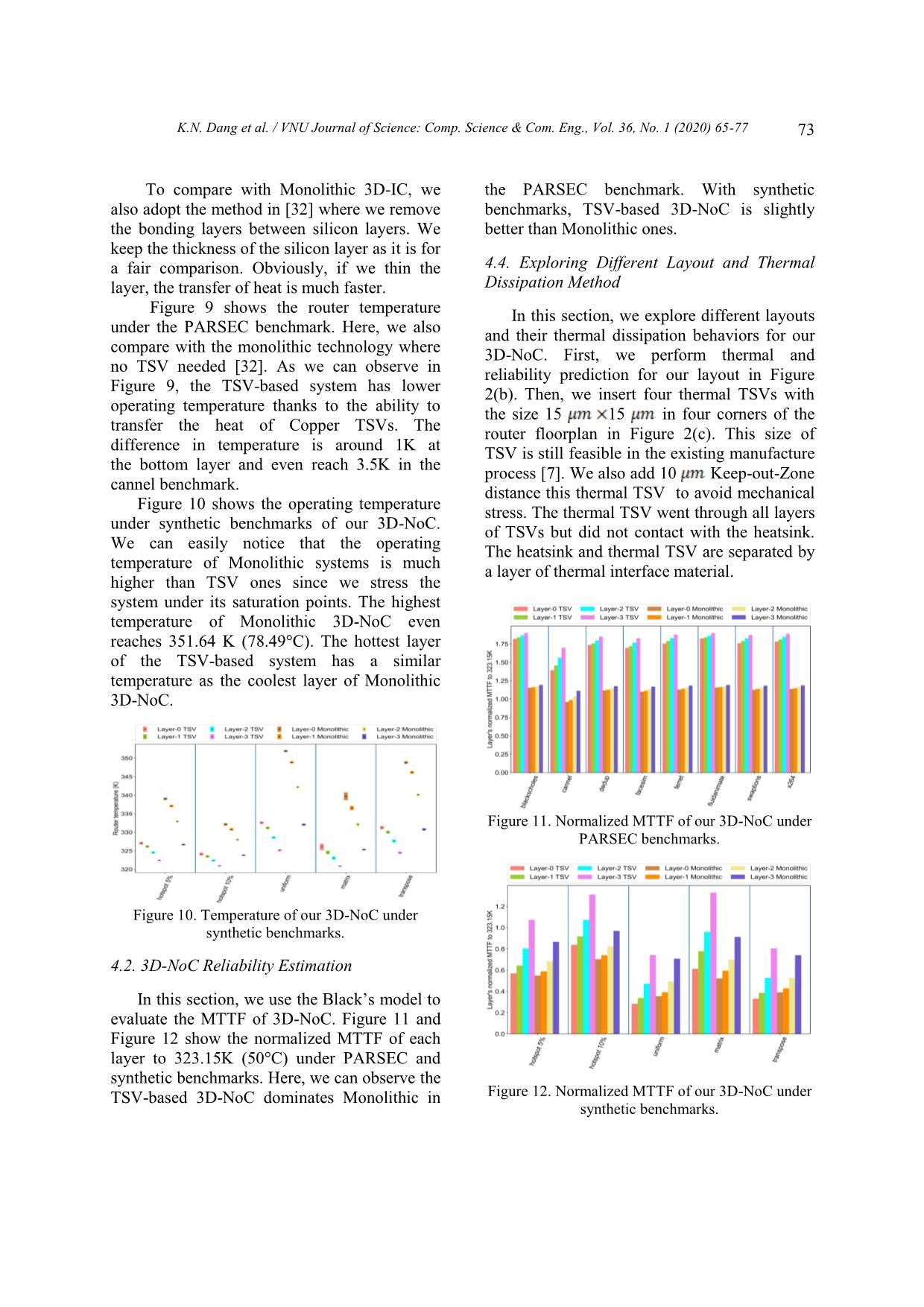

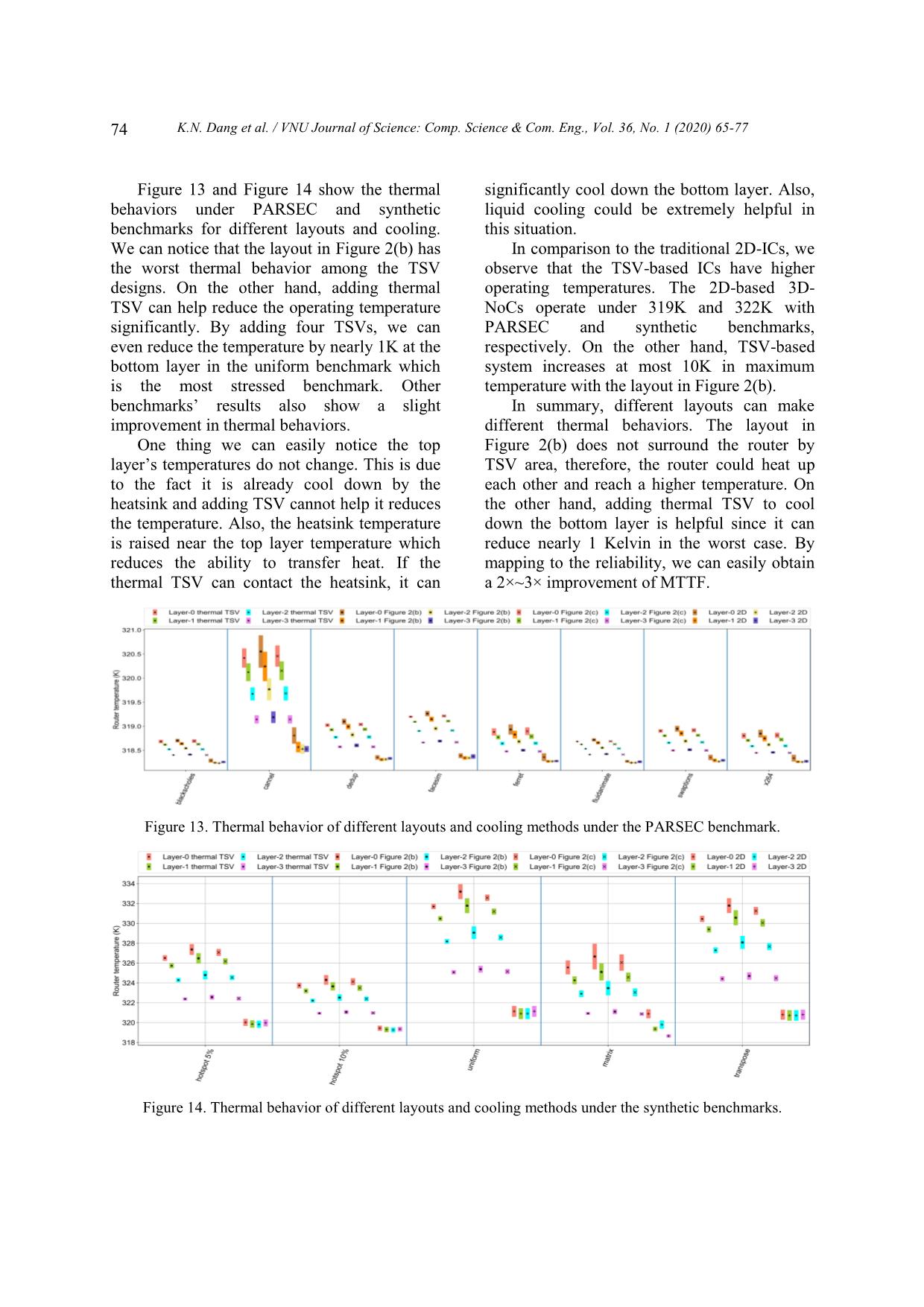

nchmark. With synthetic also adopt the method in [32] where we remove benchmarks, TSV-based 3D-NoC is slightly the bonding layers between silicon layers. We better than Monolithic ones. keep the thickness of the silicon layer as it is for a fair comparison. Obviously, if we thin the 4.4. Exploring Different Layout and Thermal layer, the transfer of heat is much faster. Dissipation Method Figure 9 shows the router temperature In this section, we explore different layouts under the PARSEC benchmark. Here, we also and their thermal dissipation behaviors for our compare with the monolithic technology where 3D-NoC. First, we perform thermal and no TSV needed [32]. As we can observe in reliability prediction for our layout in Figure Figure 9, the TSV-based system has lower 2(b). Then, we insert four thermal TSVs with operating temperature thanks to the ability to the size 15 15 in four corners of the transfer the heat of Copper TSVs. The router floorplan in Figure 2(c). This size of difference in temperature is around 1K at TSV is still feasible in the existing manufacture the bottom layer and even reach 3.5K in the process [7]. We also add 10 Keep-out-Zone cannel benchmark. distance this thermal TSV to avoid mechanical Figure 10 shows the operating temperature stress. The thermal TSV went through all layers under synthetic benchmarks of our 3D-NoC. of TSVs but did not contact with the heatsink. We can easily notice that the operating The heatsink and thermal TSV are separated by temperature of Monolithic systems is much a layer of thermal interface material. higher than TSV ones since we stress the system under its saturation points. The highest temperature of Monolithic 3D-NoC even reaches 351.64 K (78.49°C). The hottest layer of the TSV-based system has a similar temperature as the coolest layer of Monolithic 3D-NoC. Figure 11. Normalized MTTF of our 3D-NoC under PARSEC benchmarks. Figure 10. Temperature of our 3D-NoC under synthetic benchmarks. 4.2. 3D-NoC Reliability Estimation In this section, we use the Black’s model to evaluate the MTTF of 3D-NoC. Figure 11 and Figure 12 show the normalized MTTF of each layer to 323.15K (50°C) under PARSEC and synthetic benchmarks. Here, we can observe the TSV-based 3D-NoC dominates Monolithic in Figure 12. Normalized MTTF of our 3D-NoC under synthetic benchmarks. 74 K.N. Dang et al. / VNU Journal of Science: Comp. Science & Com. Eng., Vol. 36, No. 1 (2020) 65-77 Figure 13 and Figure 14 show the thermal significantly cool down the bottom layer. Also, behaviors under PARSEC and synthetic liquid cooling could be extremely helpful in benchmarks for different layouts and cooling. this situation. We can notice that the layout in Figure 2(b) has In comparison to the traditional 2D-ICs, we the worst thermal behavior among the TSV observe that the TSV-based ICs have higher designs. On the other hand, adding thermal operating temperatures. The 2D-based 3D- TSV can help reduce the operating temperature NoCs operate under 319K and 322K with significantly. By adding four TSVs, we can PARSEC and synthetic benchmarks, even reduce the temperature by nearly 1K at the respectively. On the other hand, TSV-based bottom layer in the uniform benchmark which system increases at most 10K in maximum is the most stressed benchmark. Other temperature with the layout in Figure 2(b). benchmarks’ results also show a slight In summary, different layouts can make improvement in thermal behaviors. different thermal behaviors. The layout in One thing we can easily notice the top Figure 2(b) does not surround the router by layer’s temperatures do not change. This is due TSV area, therefore, the router could heat up to the fact it is already cool down by the each other and reach a higher temperature. On heatsink and adding TSV cannot help it reduces the other hand, adding thermal TSV to cool the temperature. Also, the heatsink temperature down the bottom layer is helpful since it can is raised near the top layer temperature which reduce nearly 1 Kelvin in the worst case. By reduces the ability to transfer heat. If the mapping to the reliability, we can easily obtain thermal TSV can contact the heatsink, it can a 2×~3× improvement of MTTF. G Figure 13. Thermal behavior of different layouts and cooling methods under the PARSEC benchmark. Figure 14. Thermal behavior of different layouts and cooling methods under the synthetic benchmarks. K.N. Dang et al. / VNU Journal of Science: Comp. Science & Com. Eng., Vol. 36, No. 1 (2020) 65-77 75 4.5. Execution Time TSV-based 3D-NoCs due to two major reasons: i) TSVs act like thermal conduct devices and In this work, we evaluate the proposed ii) Monolithic 3D-ICs has a higher density than method using a system with Xeon E5-2620 8 TSV-based system. However, we would like to cores 2.1GHz, 16GB RAM and Linux note that Monolithic 3D-ICs have lower area Subsystem and PowerShell under Windows 10. cost than TSV-based systems. The platform is written under C++, Python, and Fluid cooling [7] is one of the most Bash. The execution time is measured using advanced methods to reduce the operating command time under Linux and Measure- temperature of the system. Although we have Command under Windows PowerShell. Here, not explored the ability of this method, it has the simulation time of PARSEC and synthetic shown promising efficiency for 3D-ICs [7]. benchmarks are not considered because they are With a fast velocity of the fluid, we expect the separated from our flow. As shown in Table 4, system can be cooled down significantly. all steps in our flow perform under two seconds. However, we would like to note that fluid Our method easily outperforms in terms of cooling has unknown reliability which needs to execution time the fabrication-based methods be carefully investigated for being widely used. which usually take hours regardless of designing, fabrication and assembly time [10-12]. 5. Conclusion Table 4. Execution time of the proposed flow In this work, we proposed a platform to Work Step Time quickly estimate the power, thermal behavior, Ours Power extraction (one 1.22 s and reliability of 3D-NoC systems. The method benchmark) has shown extremely short execution time. We Floorplan generate 0.095 s also analyze and simulate the reliability of TSV Temperature estimation 81 s and Monolithic 3D-ICs. Furthermore, we (one benchmark) explore and compare different layout strategies Reliability estimation (12 1.12 s and cooling methods. benchmarks) From our experiments with 3D-NoC, we [10] Reliability test 96h can realize that lower index layers have higher [11] The longest step in 1000h operating temperatures and are more critical in reliability test terms of reliability. Although this conclusion [12] Lifetime acceleration test 100-5000h cannot cover all possible cases; this is a consensus of the tested benchmark Based on Although our approach is fater than these experiments, designers can decide their real-chip testing [10-12], it cannot as accurate fault-tolerance or thermal dissipation up on as the baking tests due to the deviations during their required specification. simulation and the potential of manufacturing In the future, advanced cooling techniques variation. However, as the close-loop design such as liquid could be investigated. The impact flow, having an understand of the potential of DVFS and fault tolerance on performance reliability threat is helpful for designers. and thermal behavior also could be studied. 4.6. Discussion In this section, we would like to discuss Acknowledgments some technical details of our methods. Advantages and drawbacks are also mentioned This research is funded by the Vietnam in this part. National Foundation for Science and In our evaluation, we point out that Technology Development (NAFOSTED) under Monolithic has a higher temperature than grant number 102.01-2018.312. 76 K.N. Dang et al. / VNU Journal of Science: Comp. Science & Com. Eng., Vol. 36, No. 1 (2020) 65-77 References [10] Hamada, M. Dorothy June, J. William, Roesch, "Evaluating device reliability using wafer-level methodology", CS Mantech Conference, 2008. [1] Khanh N. Dang, Akram Ben Ahmed, Xuan Tu [11] Renesas’s Semiconductor Reliability Handbook Tran, Yuichi Okuyama, Abderazek Ben Abdallah, https://www.renesas.com/us/en/doc/products/others/r “A Comprehensive Reliability Assessment of 51zz0001ej0250.pdf/, 2017 (access 17 March 2020). Fault-Resilient Network-on-Chip Using [12] Toshiba’s Reliability Handbook Analytical Model,” IEEE Transactions on Very https://toshiba.semicon- Large Scale Integration (VLSI) Systems. 25(11) storage.com/content/dam/toshiba- (2017) 3099-3112. ss/shared/docs/design-support/reliability/reliability- https://doi.org/10.1109/TVLSI.2017.2736004. handbook-tdsc-en.pdf /, 2018 (access 17 March 2020). [2] K. Banerjee K. Banerjee, S.J. Souri, P. Kapur and [13] Zhang, Runjie, Mircea R. Stan, Kevin K.C. Saraswat, “3-D ICs: A novel chip design for Skadron, “Hotspot 6.0: Validation, improving deep-submicrometer interconnect acceleration and extension”, University of performance and systems-on-chip integration,” Virginia, Tech, Rep, 2015. Proc. IEEE. 89(5) (201) 602-633. [14] Sridhar, Arvind, et al., "3D-ICE: Fast compact https://doi.org/10.1109/5.929647. transient thermal modeling for 3D ICs with inter- [3] Khanh N. Dang, Akram Ben Ahmed, Yuichi tier liquid cooling", 2010 IEEE/ACM Okuyama, Abderazek Ben Abdallah, “Scalable International Conference on Computer-Aided design methodology and online algorithm for Design (ICCAD), IEEE, 2010. TSV-cluster defects recovery in highly reliable [15] Scott Ladenheim, Yi-Chung Chen, Milan 3D-NoC systems”, IEEE Transactions on Mihajlović, Vasilis F. Pavlidis, "The MTA: An Emerging Topics in Computing, 2017, pp. 1-14 Advanced and Versatile Thermal Simulator for (in-press). Integrated Systems", IEEE Transactions on https://doi.org/10.1109/TETC.2017.2762407. Computer-Aided Design of Integrated Circuits [4] Wong, Simon, et al. "Monolithic 3D integrated and Systems 37(12) (2018) 3123-3136. circuits" International Symposium on VLSI https://doi.org/10.1109/TCAD.2018.2789729. Technology, Systems and Applications (VLSI- [16] Erdmann, Christophe, et al., "A heterogeneous TSA), IEEE, 2007. 3D-IC consisting of two 28 nm FPGA die and 32 [5] Y.J. Park et al., “Thermal Analysis for 3D Multi- reconfigurable high-performance data converters", core Processors with Dynamic Frequency IEEE Journal of Solid-State Circuits 50(1) (2014) Scaling”, in IEEE/ACIS 9th Int, Conf, on 258-269. Computer and Information Science, Aug 2010, https://doi.org/10.1109/JSSC.2014.2357432. pp. 69-74. [17] Kahng, B. Andrew, et al., "ORION 2.0: A fast and [6] Van der Plas, Geert, et al., "Design issues and accurate NoC power and area model for early- considerations for low-cost 3-D TSV IC stage design space exploration", Design, technology". IEEE Journal of Solid-State Circuits Automation & Test in Europe Conference & 46(1) (2010) 293-307. Exhibition, IEEE, 2009. [7] D. Cuesta et al., “Thermal-aware floorplanner for [18] Lee, Seung Eun, and Nader Bagherzadeh, "A high 3D IC, including TSVs, liquid microchannels and level power model for Network-on-Chip (NoC) thermal domains optimization,” Applied Soft router", Computers & Electrical Engineering Computing 34 (2015) 164-177. 35(6) (2009) 837-845. https://doi.org/10.1016/j.asoc.2015.04.052. https://doi.org/10.1016/j.compeleceng.2008.11.023. [8] Park, Changyok, "Dummy TSV to improve [19] Lee, Seung Eun, Nader Bagherzadeh, "A variable process uniformity and heat dissipation", U.S. frequency link for a power-aware network-on- Patent 10, 181, 454, 15 Jan, 2019. chip (NoC)", Integration 42(4) (2009) 479-485. https://patents.google.com/patent/US2011021545 https://doi.org/10.1016/j.vlsi.2009.01.002. 7A1/en (access 16 March 2020). [20] Lebreton, Hugo, Pascal Vivet, "Power modeling in [9] J.R. Black, “Mass transport of aluminum by SystemC at transaction level, application to a DVFS momentum exchange with conducting architecture", 2008 IEEE Computer Society Annual electrons”, in 6th Annual Reliability Physics Symposium on VLSI, IEEE, 2008. Symposium (IEEE), IEEE, 1967, pp. 148-159. [21] Khanh N. Dang Akram Ben Ahmed, Abderazek Ben Abdallah, Xuan-Tu Tran, “TSV-OCT: A K.N. Dang et al. / VNU Journal of Science: Comp. Science & Com. Eng., Vol. 36, No. 1 (2020) 65-77 77 Scalable Online Multiple-TSV Defects [28] Bienia, Christian, et al., "The PARSEC Localization for Real-Time 3-D-IC systems” benchmark suite: Characterization and IEEE Transactions on Very Large Scale architectural implications", Proceedings of the Integration Systems 28(3) (2020) 672 - 685. 17th international conference on Parallel https://doi.org/10.1109/TVLSI.2019.2948878. architectures and compilation techniques, 2008. [22] United States of America: Department of Defense, [29] Li, Sheng, et al., "McPAT: an integrated power, area Military Handbook: Reliability Prediction of and timing modeling framework for multicore and Electronic Equipment: MIL-HDBK-217F, 1991. manycore architectures", Proceedings of the 42nd [23] J.B. Bowles, “A survey of reliability-prediction Annual IEEE/ACM International Symposium on procedures for microelectronic devices”, IEEE Microarchitecture, 2009. Trans, Rel. 41(1) (1992) 2-12. [30] J. Meng, K. Kawakami, A.K. Coskun, https://doi.org/10.1109/24.126662. “Optimizing energy efficiency of 3-d multicore [24] J. Srinivasan et al., “Lifetime reliability: Toward an systems with stacked dram under power and architectural solution”, IEEE Micro. 25(3) (2005) thermal constraints”, in DAC Design Automation 70-80. https://doi.org/10.1109/MM.2005.54. Conference 2012, IEEE, 2012, pp. 648-655. [25] NanGate Inc., “Nangate Open Cell Library 45nm” [31] Khanh N. Dang, Akram Ben Ahmed, Abderazek 2016 (accessed 16 June 2016). Ben Abdallah, Michael Corad Meyer, Xuan-Tu [26] NCSU Electronic Design Automation, Tran, “2D Parity Product Code for TSV online “FreePDK3D45 3D-IC process design kit”, fault correction and detection”, REV Journal on Electronics and Communications (in-press). tents/, 2016 (accessed 16 June 2016). [27] Binkert, Nathan, et al., "The gem5 simulator", [32] Samal, Sandeep Kumar, et al., "Fast and accurate ACM SIGARCH computer architecture news thermal modeling and optimization for monolithic 39(2) (2011) 1-7. 3D ICs", 2014 51st ACM/EDAC/IEEE Design Automation Conference (DAC), IEEE, 2014. P

File đính kèm:

thermal_distribution_and_reliability_prediction_for_3d_netwo.pdf

thermal_distribution_and_reliability_prediction_for_3d_netwo.pdf