Phương pháp đếm giấy xếp chồng dựa trên sự kết hợp độ cong cực tiểu và phát hiện đỉnh

Laminated sheet detection plays an extreme role in the manufacturing field of sheet products such

as paper, cigarette package, packing box, PCB and so on.The precision of this processing directly

affects the economic benefit of the factory and the subsequent production operation. However, the major

abtacles in this term such as the thickness of paper, material, inhomogeneous illumination, density of

noises still challenge the recent approaches. To overcome these problems, the method which combines

minimum curvature and peak detection is presented. First, the profiles of the stacked papers along the

vertical orientation of the paper are extracted. The curvatures of the profiles then are calculated after

applying Gaussian filter. Later, the central lines of the stacked papers need to be detected. The width

of the region where the curvature is negative represents the thickness of the paper. Afterward, the

positions of stacked papers can be corrected by judging the distance between the two adjacent center

points and the gray features. Finally, the counting result can be acquired by performing peak detection

on the ridge image. Our algorithm can accurately detect the abnormal paper by fusing the gray features

of the stacked papers and the distance of adjacent paper. Experimental results show that the error rate

of our method is less than 0.01% for the paper with the thickness between 0.05 mm and 0.2 mm.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Tóm tắt nội dung tài liệu: Phương pháp đếm giấy xếp chồng dựa trên sự kết hợp độ cong cực tiểu và phát hiện đỉnh

value is dark overall, resulting in a

change in the gray profile curve. The curvature

values are all greater than zero. There is no local

minimum value, and the point will be missed, so it

needs to be corrected.

Since the thickness of the paper is constant, the

distance between two adjacent sheets should

also be within a range. As shown in Figure 3,

the center points Z2 and Z6, the center distance

d1 (d2) is much smaller than (greater than) the

distance between two adjacent center points

under normal conditions. To prevent multiple or

missing inspections, the paper for the previous

step is detected. Further judgment is made at

the center point: ideally, the distance d between

the center points of two adjacent paper sheets

is a sheet thickness Wr plus the width dr of the

slit, but since the detected ridge diagram is not

an absolute straight line, the actual above, the

distance d between two adjacent paper center

points should be plus or minus three pixels on the

basis of a sheet thickness Wr and a slit width dr,

namely:

(4)

If the detected actual distance ds of two adjacent

center points is in the range of d to 2d in the

equation (4), and the gray values in the middle

2/32)(

2

)(

2

})(1{

)(

dz

dP

dz

Pd

zk

zf

zf

+

=

3±+= drWrd

25

LIÊN NGÀNH ĐIỆN - ĐIỆN TỬ - TỰ ĐỘNG HÓA

Tạp chí Nghiên cứu khoa học - Đại học Sao Đỏ, ISSN 1859-4190 Số 1(64).2019

position of the two adjacent center points and one

pixel in the left and right if it is greater than 70, it is

considered that a piece of paper has been missed

between the detected two center points; similarly,

if the ds of two adjacent center points detected

are within the range of 2d to 3d in the formula

(4), and in the one-third and two-thirds positions

of the two adjacent center points and the gray

value in the left and right pixels are greater than

70, it is considered that two sheets of paper have

been missed between the detected two center

points. And so on to judge the situation of missed

detection.

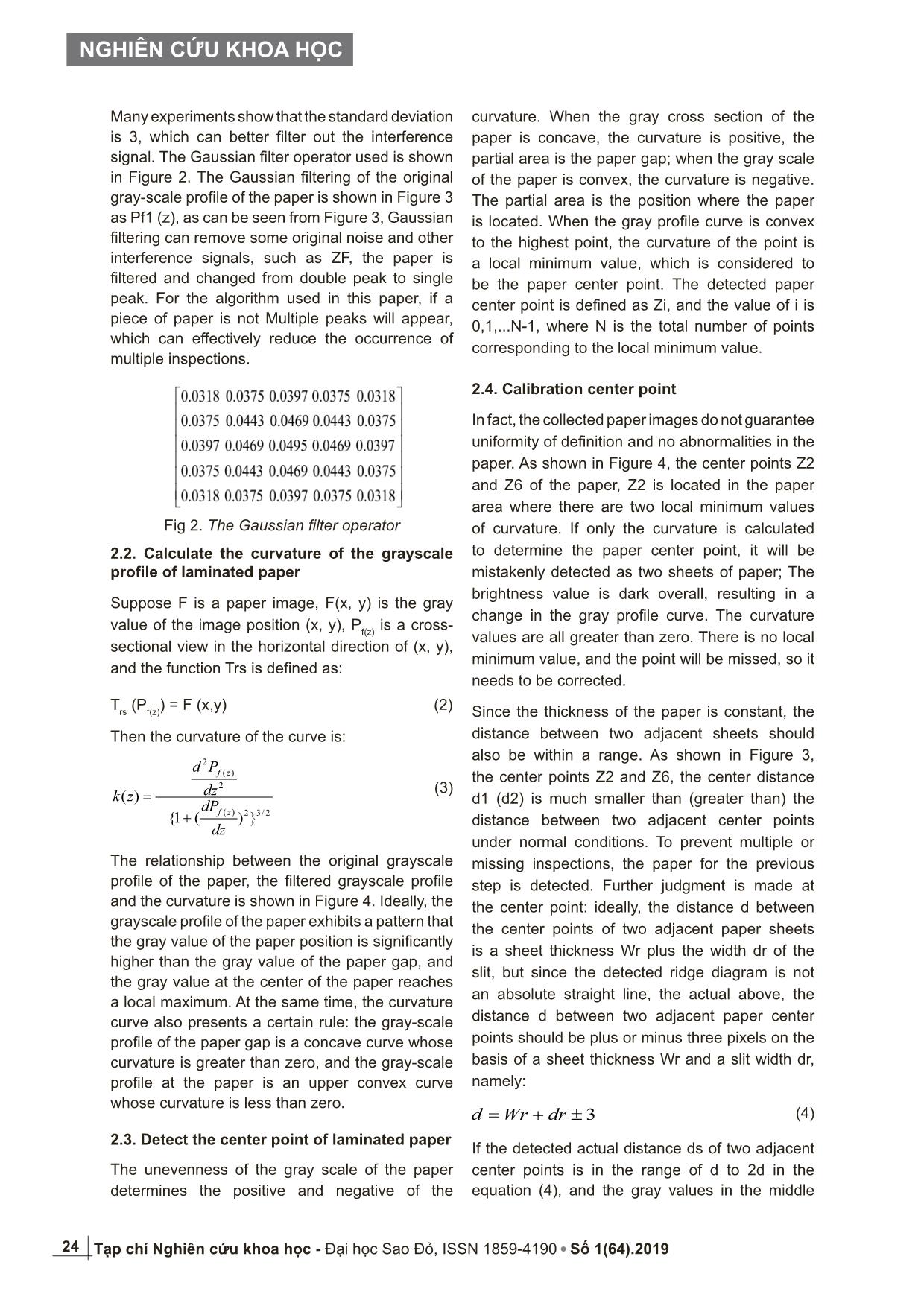

Fig.3.The relationship of the original profile,

filtered profile and curvature

If the detected actual distance ds of two adjacent

center points is smaller than d in the equation

(4), the distance between the point and another

adjacent center point is further determined, if the

point is adjacent to the two center points. If the

sum of the distances is less than d, the point is

considered to be the center point of the multi-

check and is removed.

When it is determined that two adjacent center

points have missed a piece of paper, the curvature

values of the intermediate positions of the two

adjacent center points are reversed; when it

is determined that two adjacent center points

have been detected, two sheets are missed. For

paper, the curvature values of the one-third and

two-thirds of the two adjacent center points are

reversed; and so on. The curvature value of the

missed inspection is treated as in equation (5):

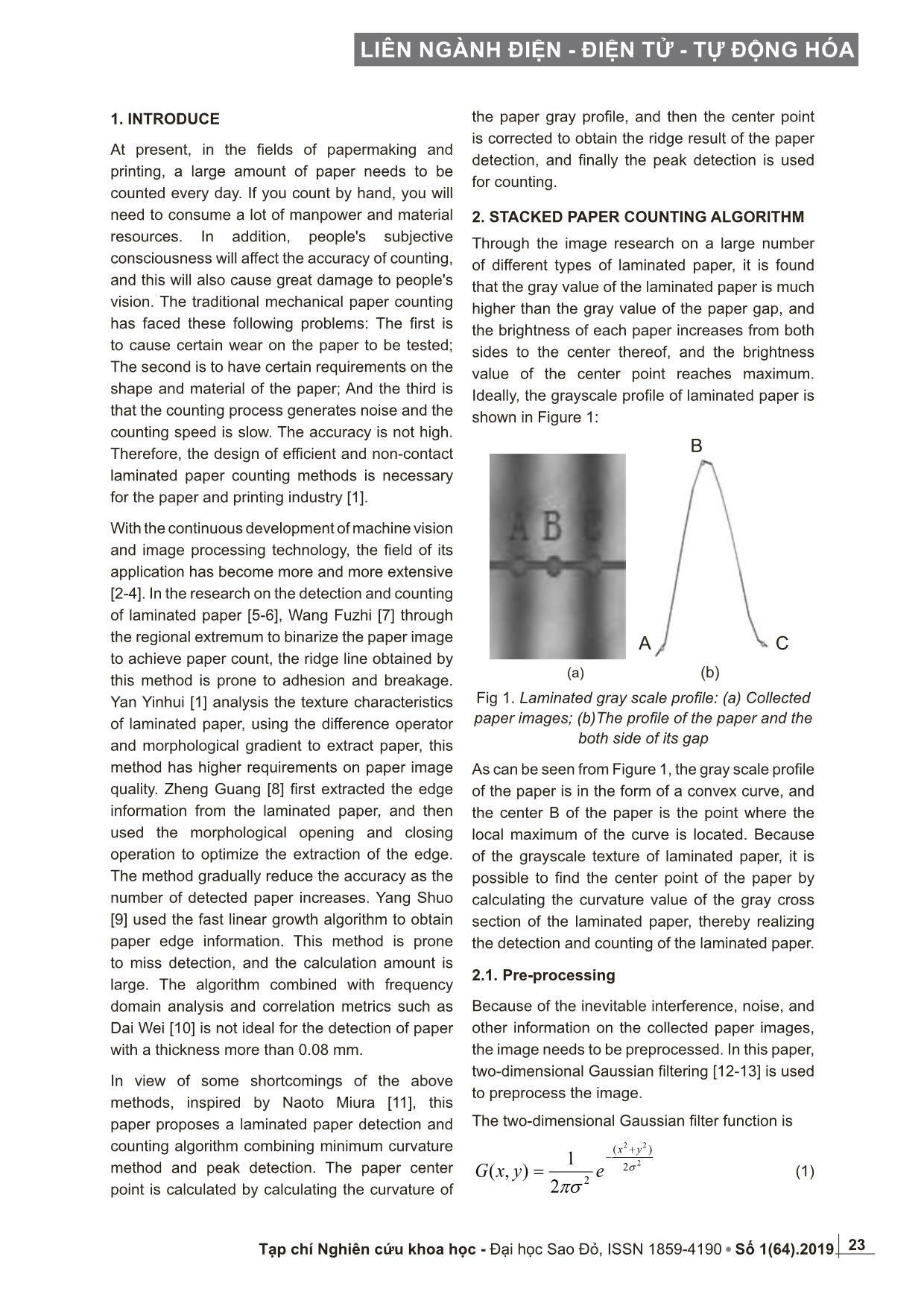

The relationship of the original profile Pf(z), filtered

profile Pf1(z) and curvature k(z) (Z1, Z2’ (multi-

detection), Z2, Z3, Z4, Z5, Z6 (less-detection), Z7

represent the paper center respectively. dr, ds(d1,

d2), Wr is the width of the gap, the distance of the

two adjacent centers and the width of the paper

respectively).

+−=+

+−=+

+−=+

)1()1(

....

)1()1(

)1()1(

22

n

k

n

k

n

k

n

k

n

k

n

k

ss

ss

ss

dndn

dd

dd

(5)

Experiments have shown that after calibration, the

missing or multi-checked paper can be detected

very well.

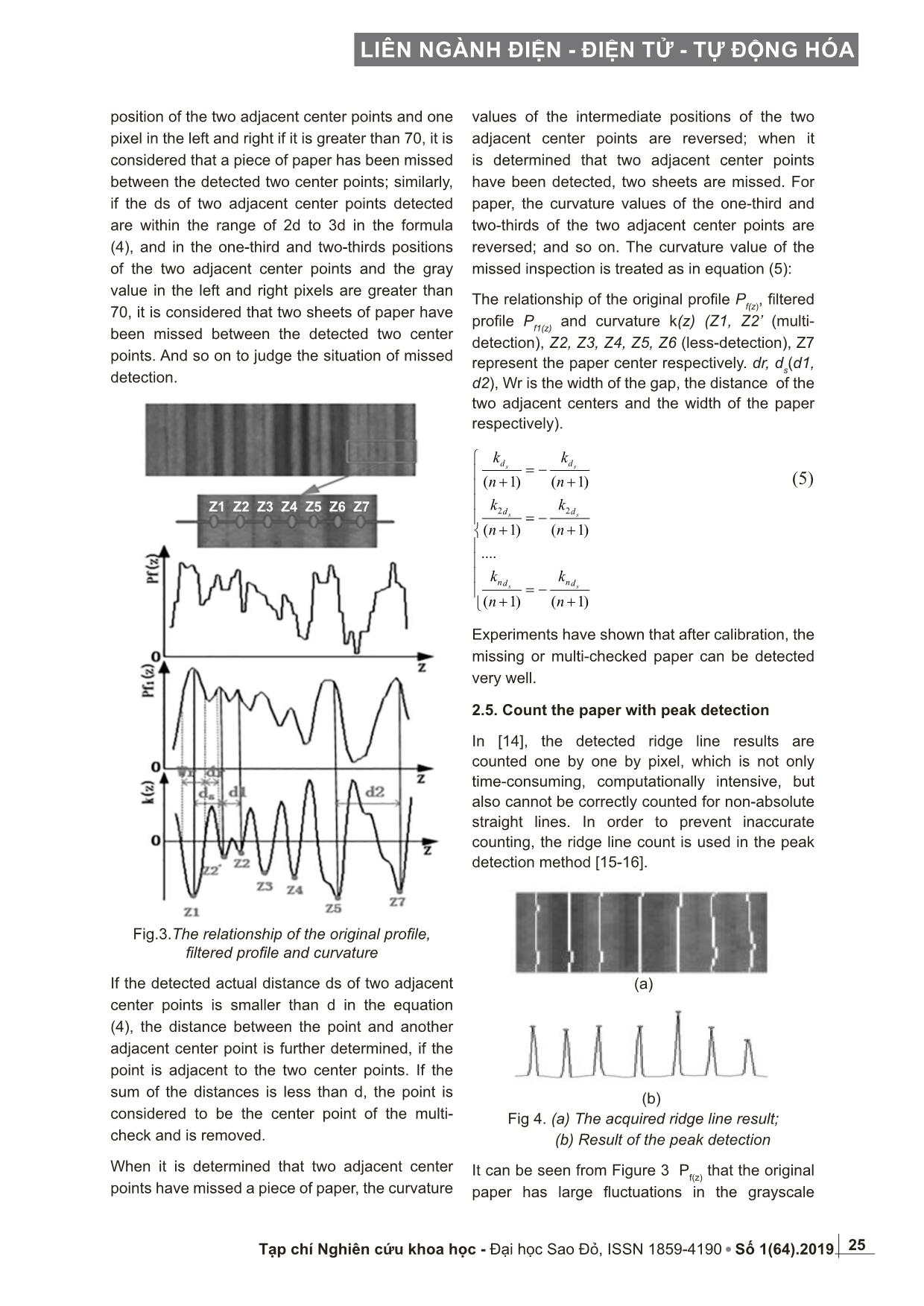

2.5. Count the paper with peak detection

In [14], the detected ridge line results are

counted one by one by pixel, which is not only

time-consuming, computationally intensive, but

also cannot be correctly counted for non-absolute

straight lines. In order to prevent inaccurate

counting, the ridge line count is used in the peak

detection method [15-16].

Fig 4. (a) The acquired ridge line result;

(b) Result of the peak detection

It can be seen from Figure 3 Pf(z) that the original

paper has large fluctuations in the grayscale

(b)

(a)

Z1 Z2 Z3 Z4 Z5 Z6 Z7

26

NGHIÊN CỨU KHOA HỌC

Tạp chí Nghiên cứu khoa học - Đại học Sao Đỏ, ISSN 1859-4190 Số 1(64).2019

profile due to some external disturbances such

as noise. If the peak value is directly detected,

it is easy to cause false detection and multiple

inspections. The result of the paper ridge obtained

by the minimum curvature method is as shown in

Figure 4.(b), and the cross-sectional view is neat

and regular, and there is no fluctuation. When the

detected ridge diagram appears broken.

When cracking or non-absolute straight line,

in order to reduce its influence on the detection

result, calculate the average value of each ridge

line as the value of the ridge line, and then perform

peak search on the processed paper ridge line, as

shown in Figure 4. For the processed paper ridge

diagram, the peak position is the center point of

the paper, and the peak number is the stack paper

count result. Experiments show that this method

can effectively reduce the interference of external

noise such as noise, and when the ridge line breaks

or the ridge line is non-absolute straight line, it can

also reduce its influence on the counting result.

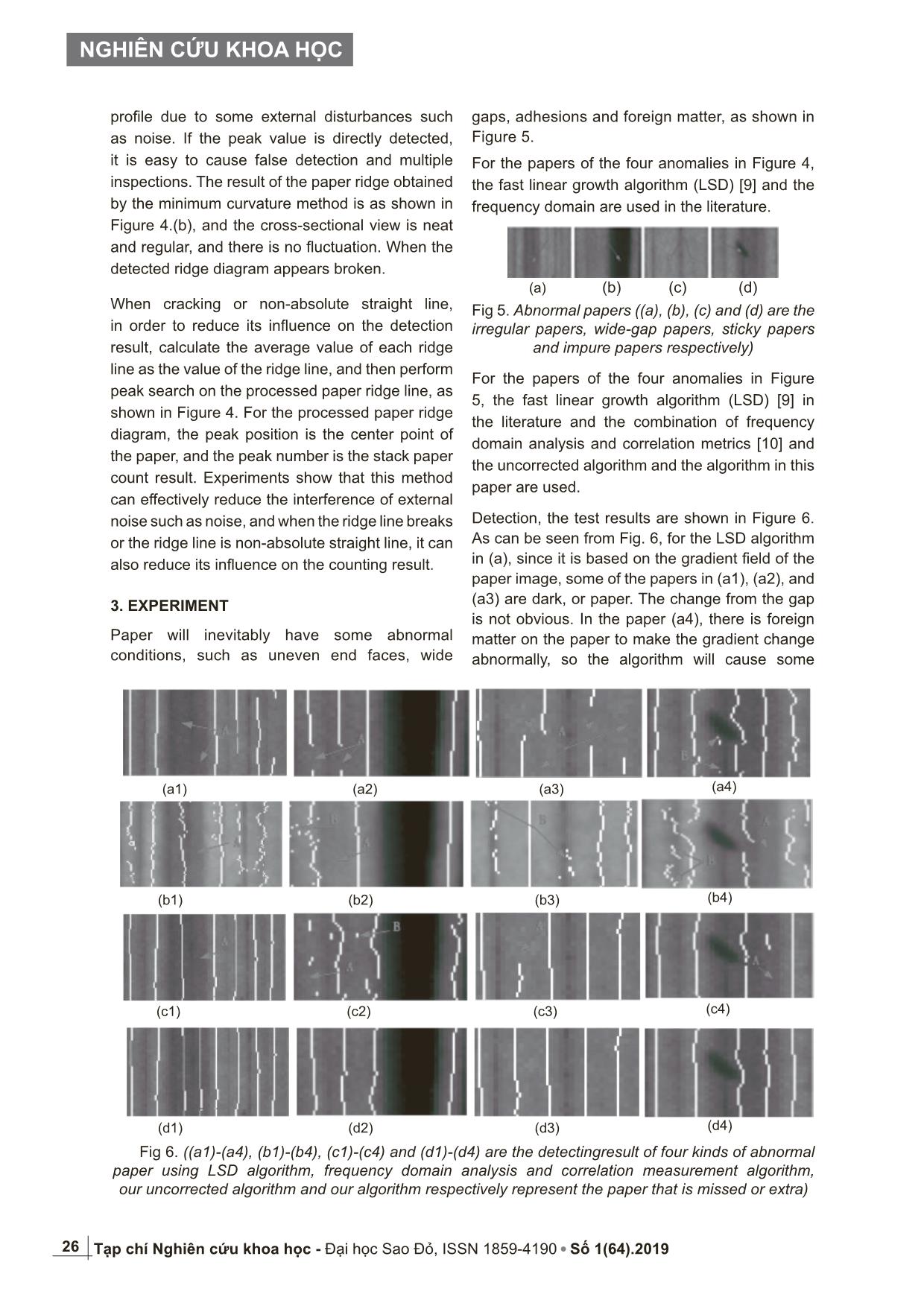

3. EXPERIMENT

Paper will inevitably have some abnormal

conditions, such as uneven end faces, wide

gaps, adhesions and foreign matter, as shown in

Figure 5.

For the papers of the four anomalies in Figure 4,

the fast linear growth algorithm (LSD) [9] and the

frequency domain are used in the literature.

(a) (b) (c) (d)

Fig 5. Abnormal papers ((a), (b), (c) and (d) are the

irregular papers, wide-gap papers, sticky papers

and impure papers respectively)

For the papers of the four anomalies in Figure

5, the fast linear growth algorithm (LSD) [9] in

the literature and the combination of frequency

domain analysis and correlation metrics [10] and

the uncorrected algorithm and the algorithm in this

paper are used.

Detection, the test results are shown in Figure 6.

As can be seen from Fig. 6, for the LSD algorithm

in (a), since it is based on the gradient field of the

paper image, some of the papers in (a1), (a2), and

(a3) are dark, or paper. The change from the gap

is not obvious. In the paper (a4), there is foreign

matter on the paper to make the gradient change

abnormally, so the algorithm will cause some

Fig 6. ((a1)-(a4), (b1)-(b4), (c1)-(c4) and (d1)-(d4) are the detectingresult of four kinds of abnormal

paper using LSD algorithm, frequency domain analysis and correlation measurement algorithm,

our uncorrected algorithm and our algorithm respectively represent the paper that is missed or extra)

(a1) (a2) (a3) (a4)

(b1) (b2) (b3) (b4)

(c1) (c2) (c3) (c4)

(d1) (d2) (d3) (d4)

27

LIÊN NGÀNH ĐIỆN - ĐIỆN TỬ - TỰ ĐỘNG HÓA

Tạp chí Nghiên cứu khoa học - Đại học Sao Đỏ, ISSN 1859-4190 Số 1(64).2019

papers (a1), (a2) and (a3) to be missed. (a4) For

the case of multiple detection; for the frequency

domain analysis and correlation metric algorithm

in (b), the comb filter used is easy to cause

misdetection for paper with local periodic anomaly,

and the correlation metric is for weak implicit modal

signals. It is easy to cause missed detection,

so the algorithm will lead to (b1), (b2), (b3) and

(b4) miss detection and multiple detection; (c) in

this paper uncorrected algorithm, for paper with

abnormal grayscale changes. The paper area may

have no minimum value of curvature, such as A in

(c1), (c2), (c3), and (c4), which makes it easy to

miss the paper. Or a sheet of paper with multiple

curvature minimum values, such as B in (c2), which

makes it easier to check the paper. The correction

algorithm in (d), on the basis of (c), combines the

grayscale characteristics of the paper with the

information of the distance of the adjacent paper

to further judge the detected paper, and fills the

missing paper, and the paper that is checked

more. Removed, which improves the accuracy

of paper detection. At the same time, in order

to further verify the accuracy of the algorithm,

different types of paper with thickness between

0.05 mm and 0.2 mm are counted. The minimum

curvature method combined with peak detection is

combined. The method can be effectively counts

of different types of paper, wherein, before the

correction accuracy is not reached 99.9%, after

subsequent counting error rate after correction is

less than 0.01%.

4. CONCLUSION

Aiming at the problem of stacking paper detection

and counting, this paper proposes a method of

detecting and counting laminated paper using the

combination of minimum curvature method and

peak detection. The basic principle is to first obtain

the gray cross-section of the stacked paper, pre-

process and calculate the curvature; then detect

the center point of the paper, and then correct the

detected center point by judging the spacing and

gray value between the adjacent two center points.

Thereby the ridge line results of the stacked paper

are obtained, and finally the peak detection is used

to count the ridge line results. Experiments show

that the algorithm of this paper can significantly

reduce the situation of multiple inspection and

missed detection of paper, can count many

different types of paper, and has high accuracy.

The algorithm in this paper has been applied to

paper testing instruments.

REFERENCES

[1]. Hui, Jiang Jin (2015), Study on paper counting

based on texture segmentation. pp.135-148.

[2]. Wang Xinxin, Xu Jiangwei, Zou Weijin, Liu

Yongfeng, Wang Xiuli (2014), Study on TFT-LCD

defect detection system[J], Journal of Electronic

Measurement and Instrument, pp. 278-284.

[3]. Wu C Z, Wang Y N (2015), Research on foreign

insoluble particulate detection method for medicinal

solution based on machine vision[J], Chinese

Journal of Scientific Instrument, 2015,36(7):1451-

1461.

[4]. Hou Weiyan,Zhang Liwei et al (2015), Design and

implementation of a bar counting measurement

system based on image processing[J], Chinese

Journal of Scientific Instrument, 2013, 34 (5):1100-

1106.

[5]. Petker Denis, Demold(de), et al. (2014), Method

and system for touchless counting of stac-ked

substrates, especially bundled banknotes [P],

United States: US20140147029A1, 20

[6]. Harba Rachid. Ferte La, Saint Aubin (fr) et al,

(2010). Card-counting device[P], United States:

US 2010/0226576A1.

[7]. Wang Fuzhi,Huang Dagui (2009), A paper grain

segmentation algorithm based on peak-valley

morphology[J], Journal of Electronic Measurement

and Instrument, 2009, 23(6): 103-107.

[8]. ZHENG Guang, CHEN You-ping, YU Wen-

yong, AI Wu (2007), Study on Paper Counting

Algorithm Based on Mathematical Morphology [J],

Microcomputer Information, 2007, 23(21): 214-215,

261.

[9]. Yang Shuo, Peng Shuang, Xiao Changyan (2015),

Fast linear growth algorithm for image analysis

and counting of laminated papers[J], Computer

Applications & Software, 2015,32(9): 188-191.

[10]. Dai Wei,Xiao Changyan (2016), Detection of

laminated paper quantity based on image frequency

domain analysis and correlation measurement[J],

Journal of Image and Graphics,2016,21(12): 1644-

1651.

[11]. Chen Xuwen, Liu Guixiong, Huang Jian (2015),

Image acquisition and surface curvature

elimination method for FPC[J], Journal of Electronic

Measurement and Instrument, 2015, 29 (6): 895-

900.

28

NGHIÊN CỨU KHOA HỌC

Tạp chí Nghiên cứu khoa học - Đại học Sao Đỏ, ISSN 1859-4190 Số 1(64).2019

Pham Thi Dieu Thuy

- Pham Thi Dieu Thuy received the B.S. degree in automation from Thai Nguyen University

of technology, Thai Nguyen, Vietnam, in 2006 and the M.S. degree in Measurement and

Control systems from Ha Noi University of Science and Technology, Ha Noi, Vietnam, in

2010. Her current research interests include medical image processing, machine vision

and machine learning.

- Email: dieuthuy303@gmail.com

- Telephone No: 0986468005

Ha Minh Tuan

- Ha Minh Tuan received the B.S degree in automation from Vietnam Maritime University,

Hai Phong, Vietnam, in 2005 and the M.S. degree in Measurement and Control systems

from Ha Noi University of Science and Technology, Ha Noi, Vietnam, in 2010. His current

research interests include medical image processing, machine vision and machine

learning.

- Email: minhtuanha031@gmail.com

THÔNG TIN VỀ TÁC GIẢ

[12]. Tao Q, Liu L (2016), Double regional evolution

based on level set for image segmentation[J],

Electronic Measurement Technology, 2016, 39 (9):

91-95.

[13]. Zhang M Y, Chen Z Y, Wang X (2013), Paper

counting algorithm based on image texture[J],

Optical Technique, 2013, 39(2): 151-156.

[14]. Chao Yang, Zengyou He and Weichuan Yu (2009),

Comparison of public peak detection algorithms for

MALDI mass spectrometry data analysis[J], BMC

bioinformatics, 2009, 10(1): 4.

[15]. ZHANG Z M, LIANG Y Z, et al (2012), Multiscale

peak alignment for chromatographic data

sets[J], Journal of chromatography A, 2012,

12(23): 93-106.

Nguyen Thi Viet Huong

- Nguyen Thi Viet Huong received the B.S. degree in Electrical Engineering Technology

from Hung Yen University of Technology and Education, Vietnam, in 2009 and the M.S.

degree in Control Engineering and Automation from Hung Yen University of Technology and

Education,Vietnam, in 2014. Her current research interests include Control Engineering

and Automation. Summary of current work: Lecturer, Faculty of Electrical Engineering,

Sao Do University.

- Email: nguyenthiviethuong1986@gmail.com

- Telephone No: 0989505045

Pham Thi Thao

- Pham Thi Thao received the B.S. degree in Electrification and power supply of enterprises

from Thai Nguyen university of Technology, Thai Nguyen, in 2002 and the M.S. degree in

Automation from Ha Noi University of Science and Technology, Ha Noi, Vietnam, in 2004.

Her current research interests include Control Engineering and Automation. Summary of

current work: Lecturer, Faculty of Electrical Engineering, Sao Do University.

- Email: phamhathao@gmail.com

- Telephone No: 0905006188

29

LIÊN NGÀNH ĐIỆN - ĐIỆN TỬ - TỰ ĐỘNG HÓA

Tạp chí Nghiên cứu khoa học - Đại học Sao Đỏ, ISSN 1859-4190 Số 1(64).2019

Luong Thi Thanh Xuan

- Luong Thi Thanh Xuan received the B.S. degree in Technology Education from Thai

Nguyen University of Technology, Thai Nguyen, in 2003 and the M.S. degree in Automation

from Thai Nguyen University of Technology, Thai Nguyen, Vietnam, in 2011. Her current

research interests include Control Engineering and Automation. Summary of current work:

Lecturer, Faculty of Electrical Engineering, Sao Do University.

- Email: thanhxuan7980@gmail.com

- Telephone No: 0982791980

File đính kèm:

phuong_phap_dem_giay_xep_chong_dua_tren_su_ket_hop_do_cong_c.pdf

phuong_phap_dem_giay_xep_chong_dua_tren_su_ket_hop_do_cong_c.pdf