Phương pháp đếm giấy dựa vào giá trị chênh lệch mức xám

In the manufacturing field of sheet products, such as paper, cigarette package, packing box, printed

circuit board (PCB), solar silicon chip and so on, the detection of laminated sheet is an essential part.

The precision of the counting directly affects the economic benefit of the factory and the subsequent

production operation. In order to reduce the high cost and noise in mechanical paper counters, paper

counting algorithms based on the gray value difference of paper have been applied and tested to

solve these problems based only on vision signals. After the images graying of neatly arranged, with

improvements to the greyscale edge of the Gabor filter, the gray pixel curve is obtained by using grayscale

differences after projecting the gray level. Based on the interval of the peaks as the location of the peak

or valley can be accurately positioned after removing the peak valley disturbances. The paper count is

then made according to the location marker. Counting results show that this method of counting paper

can be done with simple operation, while the accurate paper counting rate reaches more than 98%.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Tóm tắt nội dung tài liệu: Phương pháp đếm giấy dựa vào giá trị chênh lệch mức xám

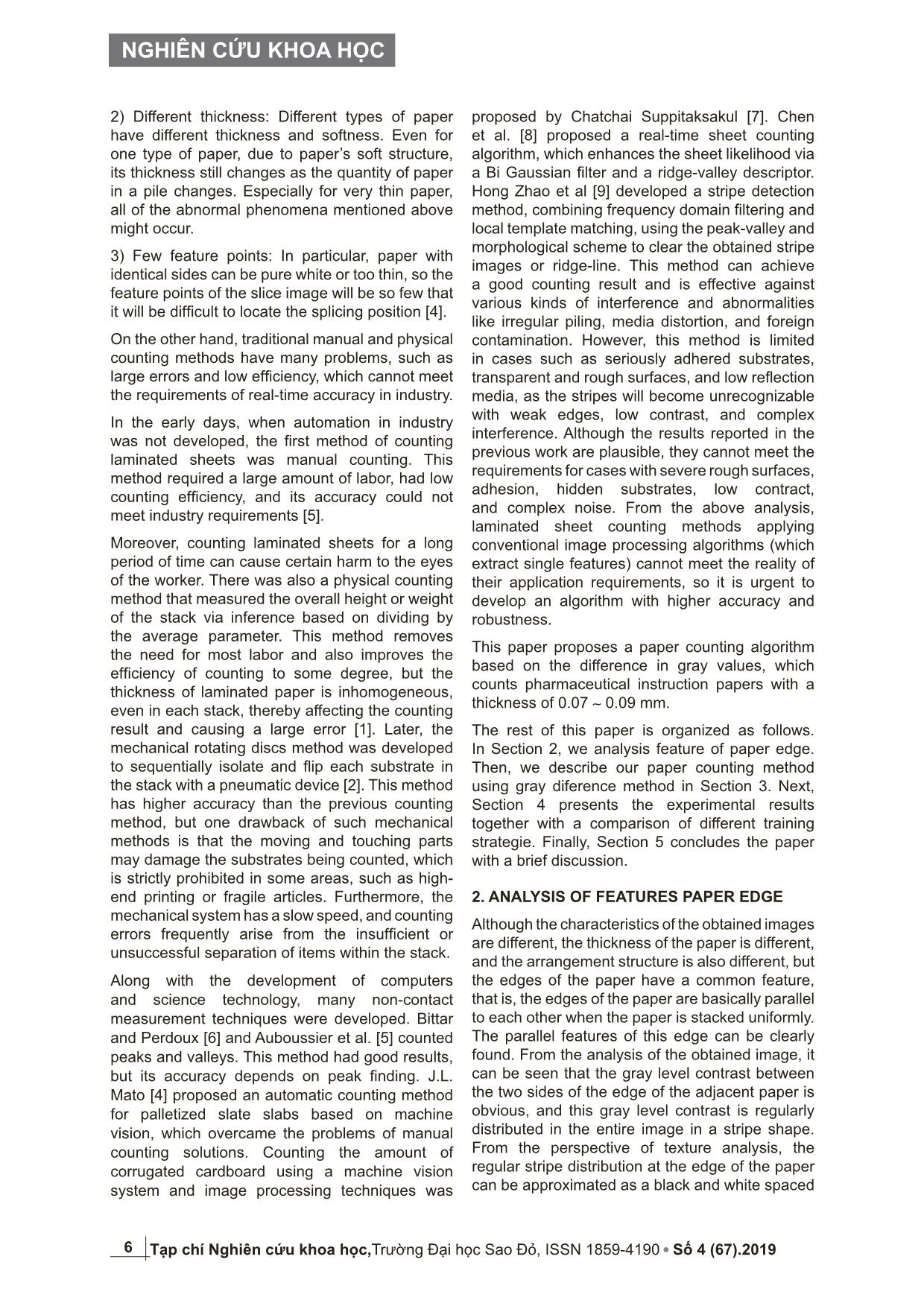

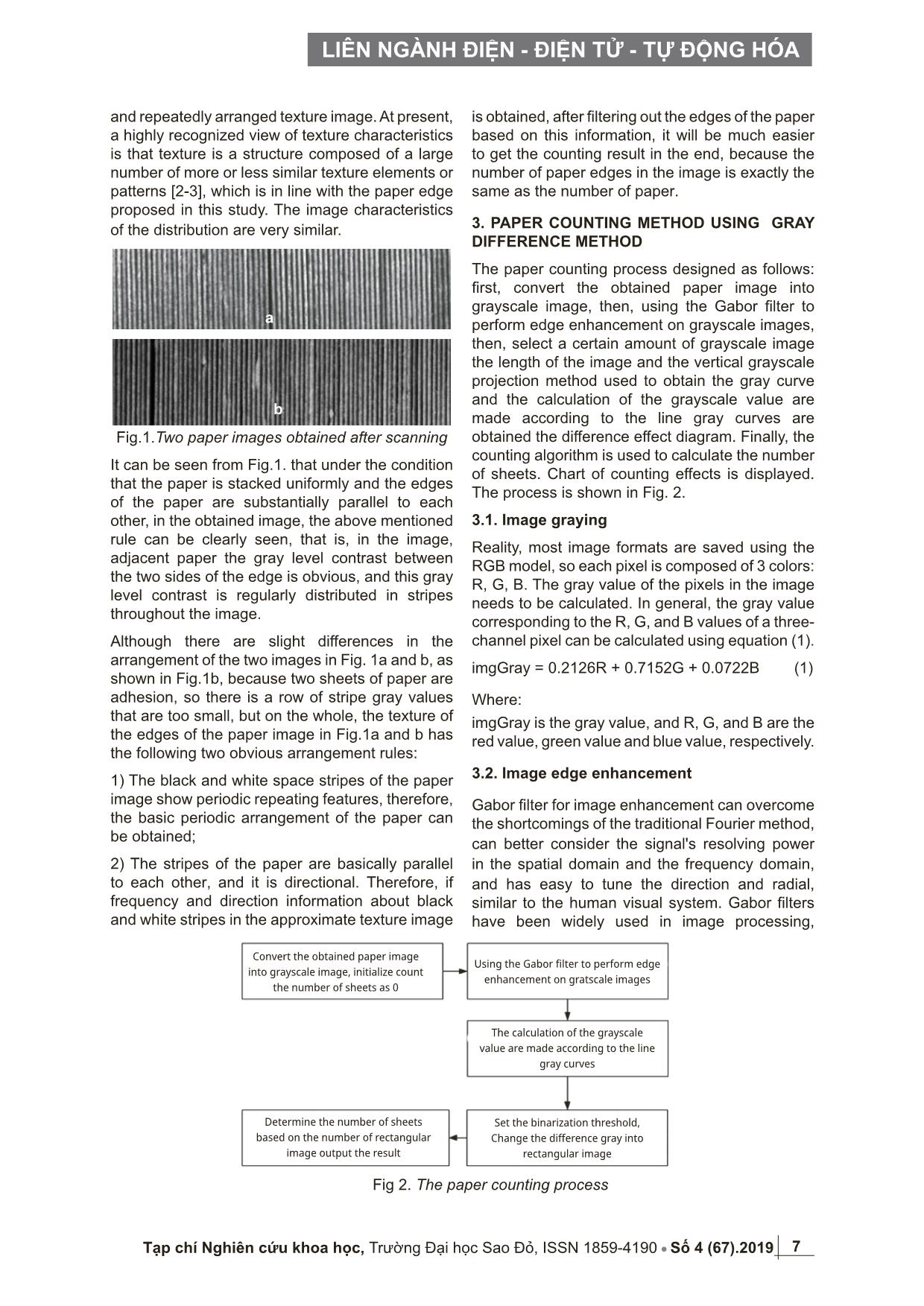

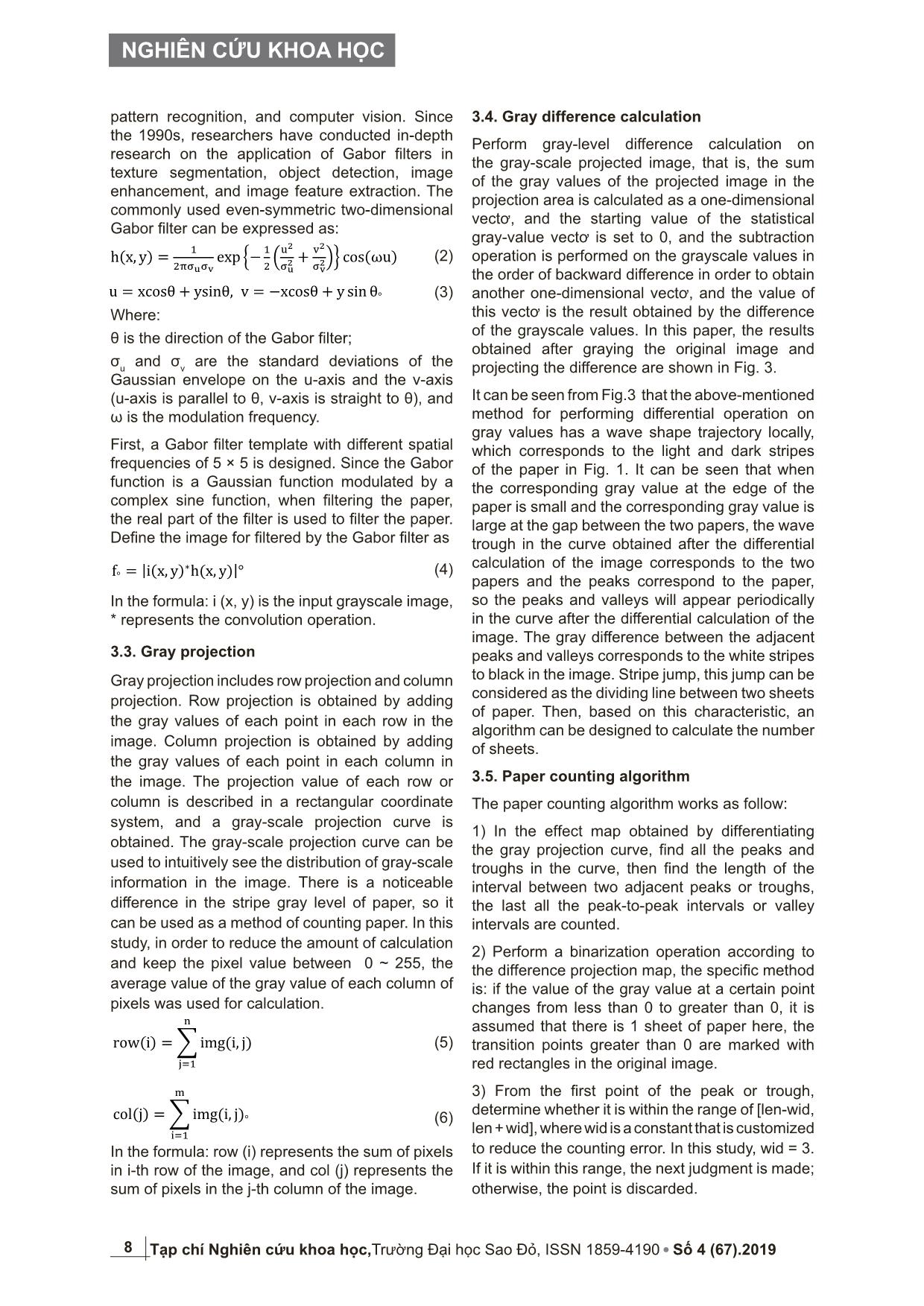

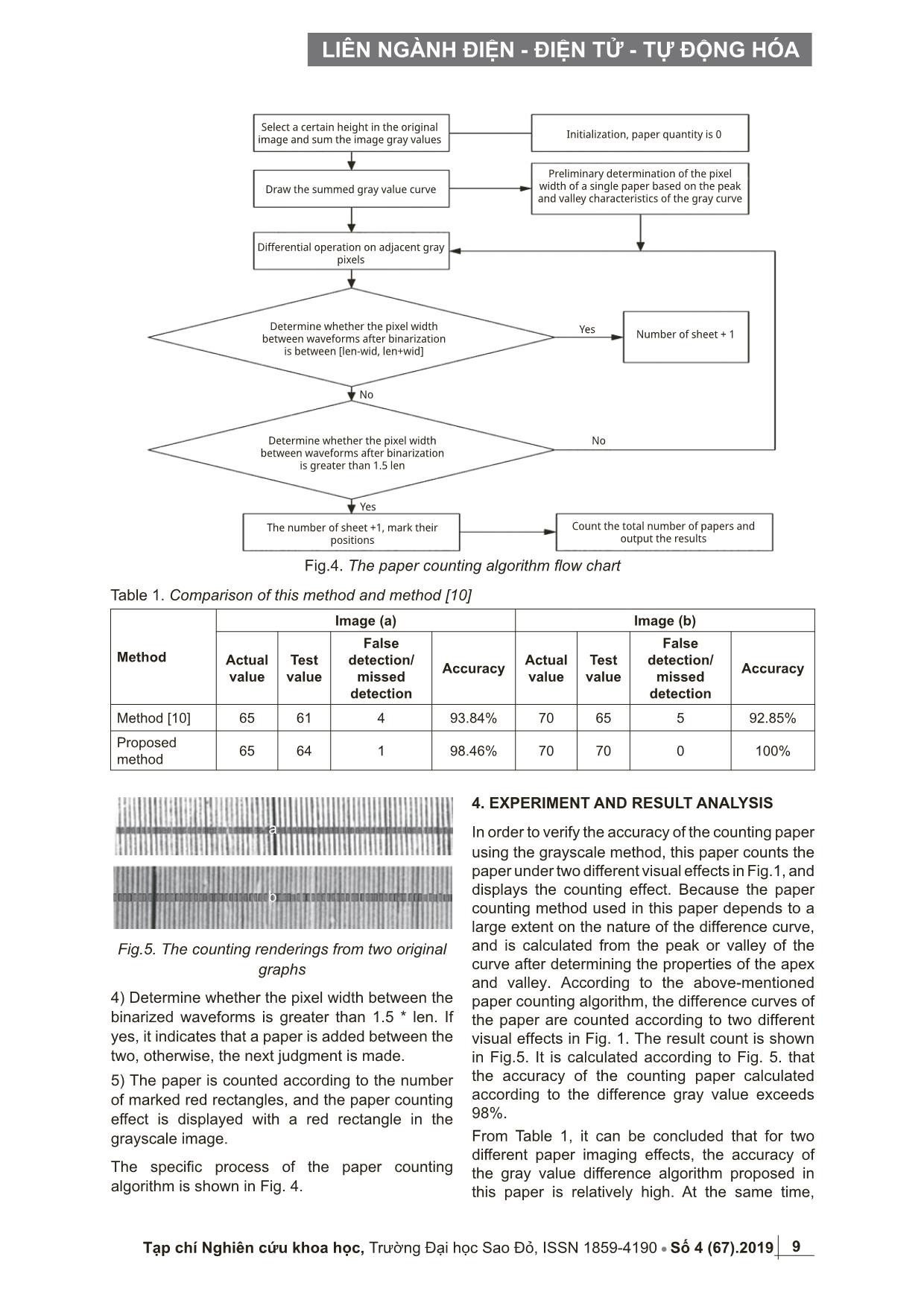

perform edge enhancement on gratscale images The calculation of the grayscale value are made according to the line gray curves Set the binarization threshold, Change the difference gray into rectangular image Determine the number of sheets based on the number of rectangular image output the result 8NGHIÊN CỨU KHOA HỌC Tạp chí Nghiên cứu khoa học,Trường Đại học Sao Đỏ, ISSN 1859-4190 Số 4 (67).2019 pattern recognition, and computer vision. Since the 1990s, researchers have conducted in-depth research on the application of Gabor filters in texture segmentation, object detection, image enhancement, and image feature extraction. The commonly used even-symmetric two-dimensional Gabor filter can be expressed as: (2) (3) Where: θ is the direction of the Gabor filter; σu and σv are the standard deviations of the Gaussian envelope on the u-axis and the v-axis (u-axis is parallel to θ, v-axis is straight to θ), and ω is the modulation frequency. First, a Gabor filter template with different spatial frequencies of 5 × 5 is designed. Since the Gabor function is a Gaussian function modulated by a complex sine function, when filtering the paper, the real part of the filter is used to filter the paper. Define the image for filtered by the Gabor filter as (4) In the formula: i (x, y) is the input grayscale image, * represents the convolution operation. 3.3. Gray projection Gray projection includes row projection and column projection. Row projection is obtained by adding the gray values of each point in each row in the image. Column projection is obtained by adding the gray values of each point in each column in the image. The projection value of each row or column is described in a rectangular coordinate system, and a gray-scale projection curve is obtained. The gray-scale projection curve can be used to intuitively see the distribution of gray-scale information in the image. There is a noticeable difference in the stripe gray level of paper, so it can be used as a method of counting paper. In this study, in order to reduce the amount of calculation and keep the pixel value between 0 ~ 255, the average value of the gray value of each column of pixels was used for calculation. In the formula: row (i) represents the sum of pixels in i-th row of the image, and col (j) represents the sum of pixels in the j-th column of the image. 3.4. Gray difference calculation Perform gray-level difference calculation on the gray-scale projected image, that is, the sum of the gray values of the projected image in the projection area is calculated as a one-dimensional vectơ, and the starting value of the statistical gray-value vectơ is set to 0, and the subtraction operation is performed on the grayscale values in the order of backward difference in order to obtain another one-dimensional vectơ, and the value of this vectơ is the result obtained by the difference of the grayscale values. In this paper, the results obtained after graying the original image and projecting the difference are shown in Fig. 3. It can be seen from Fig.3 that the above-mentioned method for performing differential operation on gray values has a wave shape trajectory locally, which corresponds to the light and dark stripes of the paper in Fig. 1. It can be seen that when the corresponding gray value at the edge of the paper is small and the corresponding gray value is large at the gap between the two papers, the wave trough in the curve obtained after the differential calculation of the image corresponds to the two papers and the peaks correspond to the paper, so the peaks and valleys will appear periodically in the curve after the differential calculation of the image. The gray difference between the adjacent peaks and valleys corresponds to the white stripes to black in the image. Stripe jump, this jump can be considered as the dividing line between two sheets of paper. Then, based on this characteristic, an algorithm can be designed to calculate the number of sheets. 3.5. Paper counting algorithm The paper counting algorithm works as follow: 1) In the effect map obtained by differentiating the gray projection curve, find all the peaks and troughs in the curve, then find the length of the interval between two adjacent peaks or troughs, the last all the peak-to-peak intervals or valley intervals are counted. 2) Perform a binarization operation according to the difference projection map, the specific method is: if the value of the gray value at a certain point changes from less than 0 to greater than 0, it is assumed that there is 1 sheet of paper here, the transition points greater than 0 are marked with red rectangles in the original image. 3) From the first point of the peak or trough, determine whether it is within the range of [len-wid, len + wid], where wid is a constant that is customized to reduce the counting error. In this study, wid = 3. If it is within this range, the next judgment is made; otherwise, the point is discarded. h(x, y) = !"#$!$" exp *− !" ,%#$!# + &#$"#./ cos(ωu) u = xcosθ + ysinθ, v = −xcosθ + y sin θ° f° = |i(x, y)∗h(x, y)|° (5) (6) row(i) = (img(i, j)!"#$ col(j) = (img(i, j)°&'#$ 9LIÊN NGÀNH ĐIỆN - ĐIỆN TỬ - TỰ ĐỘNG HÓA Tạp chí Nghiên cứu khoa học, Trường Đại học Sao Đỏ, ISSN 1859-4190 Số 4 (67).2019 Fig.4. The paper counting algorithm flow chart Table 1. Comparison of this method and method [10] a b Fig.5. The counting renderings from two original graphs 4) Determine whether the pixel width between the binarized waveforms is greater than 1.5 * len. If yes, it indicates that a paper is added between the two, otherwise, the next judgment is made. 5) The paper is counted according to the number of marked red rectangles, and the paper counting effect is displayed with a red rectangle in the grayscale image. The specific process of the paper counting algorithm is shown in Fig. 4. 4. EXPERIMENT AND RESULT ANALYSIS In order to verify the accuracy of the counting paper using the grayscale method, this paper counts the paper under two different visual effects in Fig.1, and displays the counting effect. Because the paper counting method used in this paper depends to a large extent on the nature of the difference curve, and is calculated from the peak or valley of the curve after determining the properties of the apex and valley. According to the above-mentioned paper counting algorithm, the difference curves of the paper are counted according to two different visual effects in Fig. 1. The result count is shown in Fig.5. It is calculated according to Fig. 5. that the accuracy of the counting paper calculated according to the difference gray value exceeds 98%. From Table 1, it can be concluded that for two different paper imaging effects, the accuracy of the gray value difference algorithm proposed in this paper is relatively high. At the same time, Method Image (a) Image (b) Actual value Test value False detection/ missed detection Accuracy Actual value Test value False detection/ missed detection Accuracy Method [10] 65 61 4 93.84% 70 65 5 92.85% Proposed method 65 64 1 98.46% 70 70 0 100% Select a certain height in the original image and sum the image gray values Initialization, paper quantity is 0 Draw the summed gray value curve Differential operation on adjacent gray pixels Preliminary determination of the pixel width of a single paper based on the peak and valley characteristics of the gray curve Determine whether the pixel width between waveforms after binarization is between [len-wid, len+wid] Yes Yes Number of sheet + 1 Determine whether the pixel width between waveforms after binarization is greater than 1.5 len No No The number of sheet +1, mark their positions Count the total number of papers and output the results 10 NGHIÊN CỨU KHOA HỌC Tạp chí Nghiên cứu khoa học,Trường Đại học Sao Đỏ, ISSN 1859-4190 Số 4 (67).2019 the accuracy of the method used in this paper has reached more than 98%, especially in the original image b. Although there are two papers stuck together, proposes algorithm is still able to accurately identify and detect the number of paper, which is greatly improved and improved compared to the method of edge extraction directly using Gabor filters. The reason why the algorithm used in this paper is better than the algorithm that directly applies the Gabor filter to the paper edge extraction is because in this algorithm, the properties between adjacent stripes of the paper are analyzed and processed, and the gap between papers The accurate positioning was performed, the number of false detections and missed detections was reduced, and the counting accuracy was improved. 5. CONCLUSION Based on the analysis of the above experimental results, it is known that in the case of neatly arranged papers, based on obtaining a light and dark stripe image, this paper uses a method based on gray value difference to count the number of papers. Under the condition that the gray value is differentiated, the fundamental reason why this paper counting method works well is that the difference method can better extract the stripe characteristics of the paper, because the light and dark stripes are the fundamental basis for judging the number of papers, that is, by the gray level difference of the black and white stripes realizes the analysis of the image characteristics, and at the same time, the number of papers is obtained by accurately positioning the peaks or valleys in the difference curve. The paper counting algorithm based on gray difference can realize the function of paper counting, but there are still some problems in this new paper counting method, such as the counting accuracy in the case of large differences in paper thickness and uneven alignment between papers, etc. This will be the focus of the next research. REFERENCES [1] Jian Gao, Xiao Wang An Apparatus and Method for Stacked Sheet Counting with camera Array, IEEE Latin merica Transactions 2013, 978-1- 4799-0333-7 [2] J. G. A. Barbedo, A Review on Methods for Automatic Counting of Objects in Digital Images, IEEE Latin America Transactions 2012, 10, (5), 2112-2124. [3] Junya Sato, Toru Koide, Yuki Kisi, Basic Study on Facial Oil Blotting Paper Counting Using a Webcam.IEEE Transactions on Instrumentation and Measurement 18 October 2018. [4] Mato, J. L.; Alvarez Souto, M.; Besteiro, R.; Moledo,J.A, Automated counting of palletized slate slabs based on machine vision, in Proc. 39th Annu. Conf. IEEE Ind. Electron. Soc. (IECON), Vienna, Austria 2013, pp. 2378-2383. [5] Auboussier,E.; Berthe, B.; Fumey,T., Device for counting stacked products. U.S. Patent May 16, 2006, (7045 765). [6] Perdoux, D.; Bachar Bittar; Gilles Leroux S.A., Device for counting products stacked side-by- side, U.S. Patent Nov. 11, 1997, 5 686 729. [7] Chatchai Suppitaksakul; Rattakorn, M., Machine vision system for counting the number of corrugated cardboard. In Proc. Int. Elect. Eng. Congr, (IEECON), pp. 1-4. 2014. [8] Chen T.; Wang. Y.N; Xiao C.Y., An Apparatus and Method for Real-Time Stacked Sheets Counting With Line-Scan Cameras, IEEE Transactions on Instrumentation and Measurement 2015, (64(7):1876-1884), 1876-1884. [9] Hong Zhao; Rong D; Xiao, ChangYan, A Machine Vision System for Stacked Substrates Counting With a Robust Stripe Detection Algorithm, IEEE TRANSACTIONS ON SYSTEMS, MAN, AND CYBERNETICS: SYSTEMS 2017, 2168-2216 c 2017 IEEE., (10.1109/TSMC.2017.2766441). [10] Li Yi, Ruan Qiuqi. Algorithm of Paper Counting Based on Texture Analysis[J]. Journal of Image and Graphics, 2004, 9(9), 1042-1048. Pham Thi Dieu Thuy - Pham Thi Dieu Thuy received the B.S. degree in Automation from Thai Nguyen University of Technology, Thai Nguyen, Viet Nam + In 2006 and the M.S. degree in Measurement and Control systems from Ha Noi University of Science and Technology, Ha Noi, Viet Nam + In 2010: Her current research interests include medical image processing, machine vision and machine learning - Email: dieuthuy303@gmail.com - Telephone No: 0986468005 AUTHORS BIOGRAPHY 11 LIÊN NGÀNH ĐIỆN - ĐIỆN TỬ - TỰ ĐỘNG HÓA Tạp chí Nghiên cứu khoa học, Trường Đại học Sao Đỏ, ISSN 1859-4190 Số 4 (67).2019 Ha Minh Tuan - Ha Minh Tuan received the B.S. degree in Automation from Viet Nam Maritime University, Hai Phong, Viet Nam + In 2005 and the M.S. degree in Measurement and Control systems from Ha Noi University of Science and Technology, Ha Noi, Viet Nam + In 2010: His current research interests include medical image processing, machine vision and machine learning - Email: minhtuanha031@gmail.com - Telephone No: 0977536826 Luong Thi Thanh Xuan - Luong Thi Thanh Xuan received the B.S. degree in Technology Education from Thai Nguyen University of Technology, Thai Nguyen + In 2003 and the M.S. degree in Automation from Thai Nguyen University of Technology, Thai Nguyen, Viet Nam + In 2011: Her current research interests include Control Engineering and Automation. Summary of current work: Lecturer, Faculty of Electrical Engineering, Sao Do University - Email: thanhxuan7980@gmail.com - Telephone No: 0982791980 Changyan Xiao - College of Electrical and Information Engineering, Hunan University, Changsha, China - Changyan Xiao received the B.Eng. and M.S. degrees in mechanical and electronic engineering from the National University of Defense Technology, Changsha, China, in 1994 and 1997, respectively, and the Ph.D. degree in biomedical engineering from Shanghai Jiao Tong University, Shanghai, China, in 2005. - He was a Visiting Post-Doctoral Researcher with the Division of Image Processing, Leiden University Medical Center, Leiden, The Netherlands, from 2008 to 2009. Since 2005, he has been an Associate Professor and a Full Professor with the College of Electrical and Information Engineering, Hunan University, Changsha. His current research interests include medical imaging, machine vision, and embedded instrument. - Email: c.xiao.@hnu.edu.cn Nguyen Thi Viet Huong - Nguyen Thi Viet Huong received the B.S. degree in Electrical Engineering Technology from Hung Yen University of Technology and Education, Viet Nam, in 2009 and the M.S. degree in Control Engineering and Automation from Hung Yen University of Technology and Education,Viet Nam, in 2014. Her current research interests include Control Engineering and Automation. Summary of current work: Lecturer, Faculty of Electrical Engineering, Sao Do University. - Email: nguyenthiviethuong1986 @gmail.com - Telephone No: 0911311086

File đính kèm:

phuong_phap_dem_giay_dua_vao_gia_tri_chenh_lech_muc_xam.pdf

phuong_phap_dem_giay_dua_vao_gia_tri_chenh_lech_muc_xam.pdf