Final breakdown on water tree degraded polymer insulation

This report deals with the mechanism of the final breakdown of polymeric

power cables which have been degraded by water trees. Water treeing is one of the major

degradation mechanisms in cable insulation. It has been believed that the final breakdown

takes place when a water tree penetrates the insulation. In order to reproduce penetrating

water trees in a film specimen, a double layer specimen with low-density polyethylene films

was subjected to an aging test to generate water trees. After confirming that penetrating

water trees had bridged across one layer of the ”double-layer” specimen, the breakdown

test was performed with several kinds of combinations of degraded and non-degraded films

by applying an AC voltage. It was concluded from the result that the penetrated water

tree region would withstand relatively high voltage stresses if the ambient relative humidity

was as low as 59 %, however, the breakdown voltage rapidly drops at higher humidities.

Finally, it was suggested that, under less humid conditions, a water tree would extend until

it bridges across the insulation without causing breakdown, however, the breakdown would

likely take place when the ambient humidity turns to be higher.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Tóm tắt nội dung tài liệu: Final breakdown on water tree degraded polymer insulation

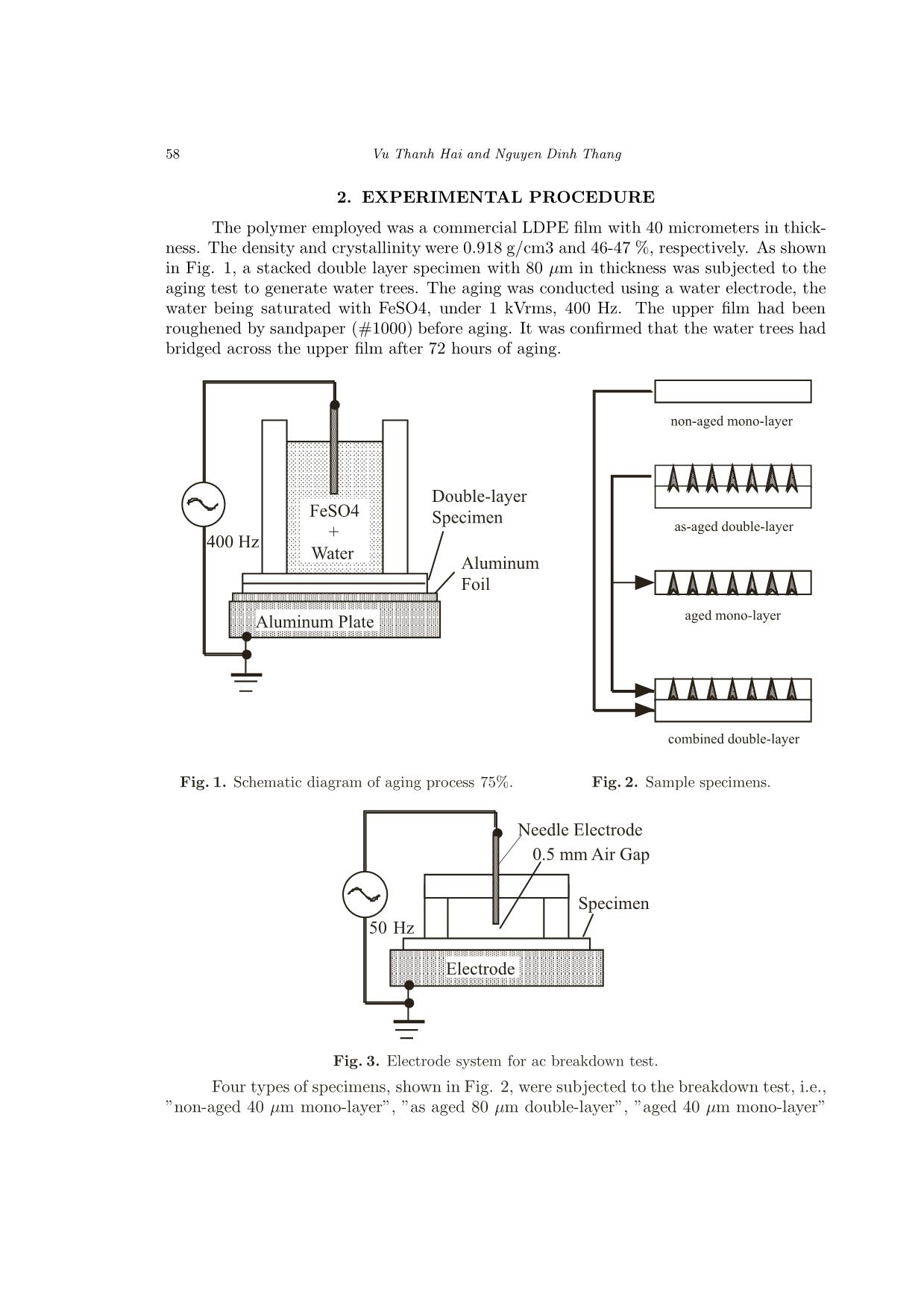

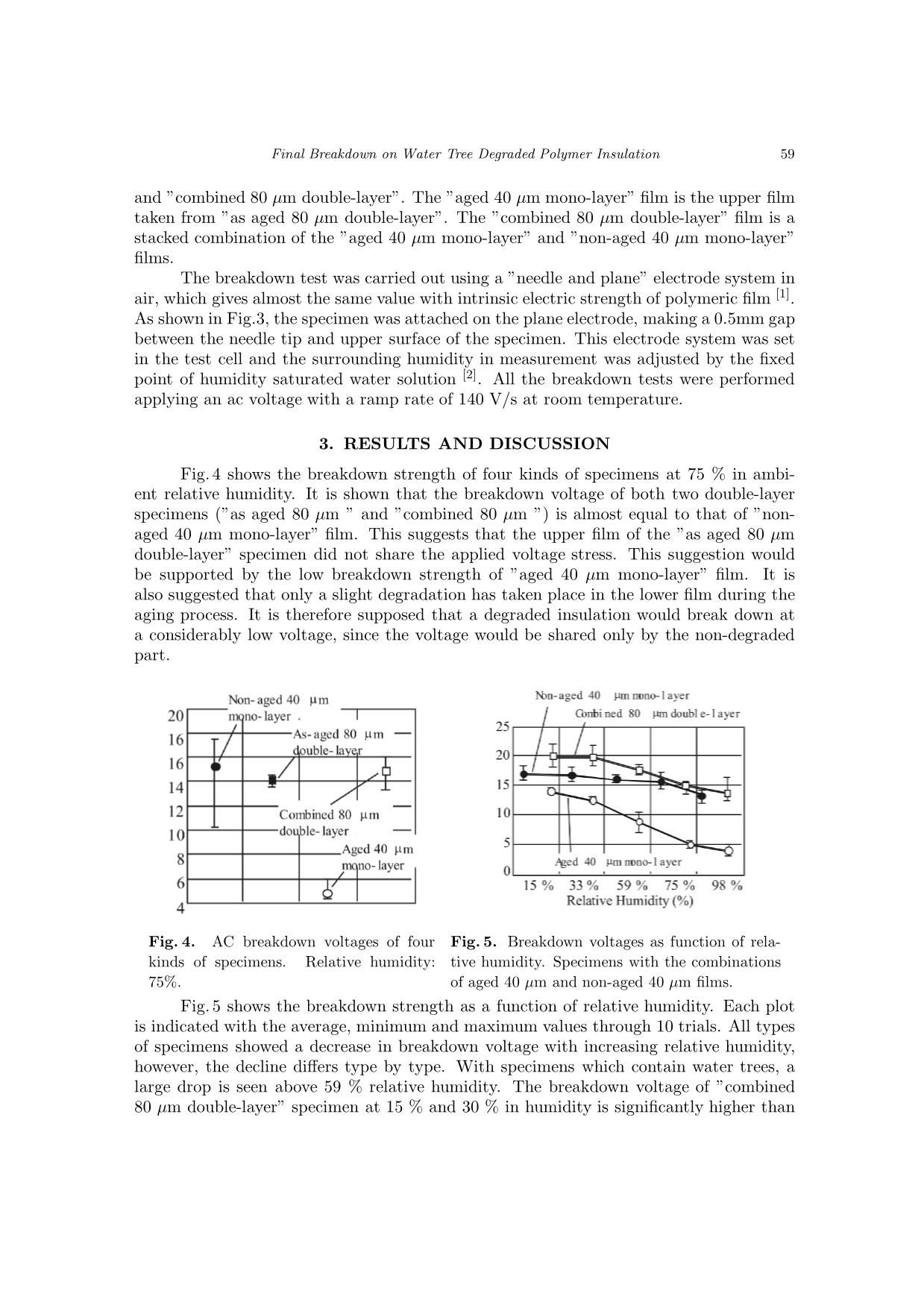

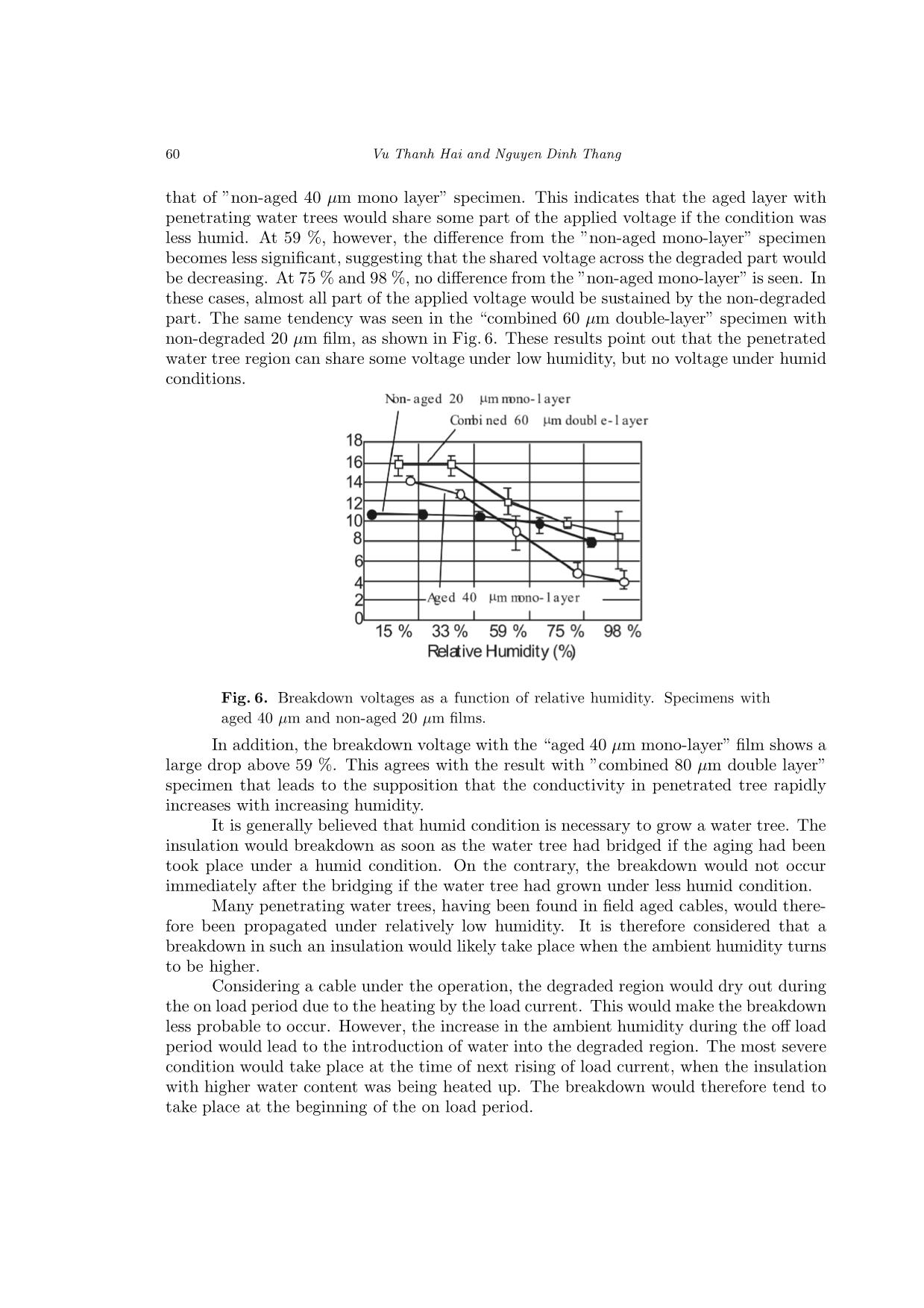

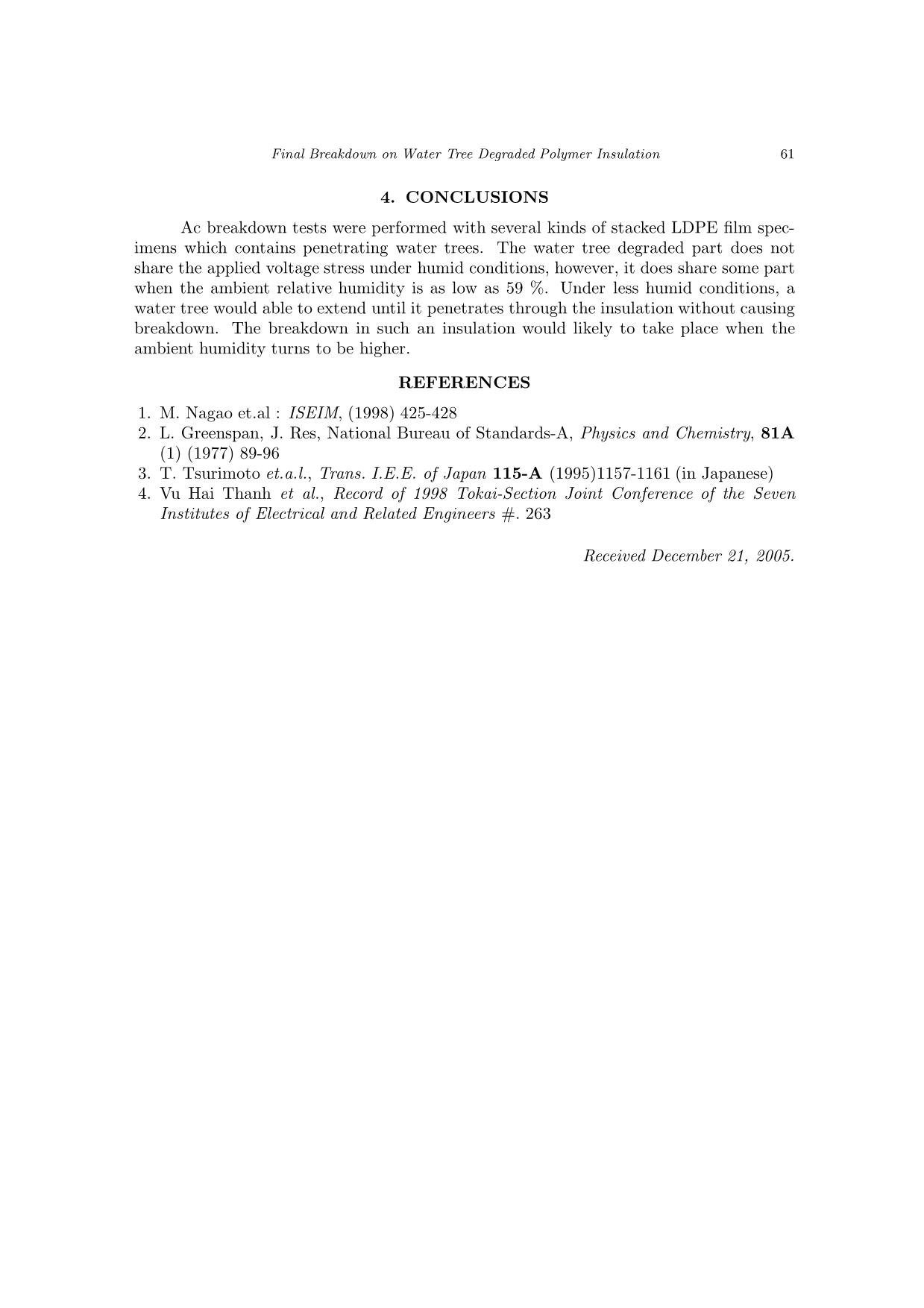

Advances in Natural Sciences, Vol. 7, No. 1& 2 (2006) (57– 61) Materials Science FINAL BREAKDOWN ON WATER TREE DEGRADED POLYMER INSULATION Vu Thanh Hai Institute of Energy, Electricity of Vietnam Nguyen Dinh Thang Hanoi University of Technology Abstract. This report deals with the mechanism of the final breakdown of polymeric power cables which have been degraded by water trees. Water treeing is one of the major degradation mechanisms in cable insulation. It has been believed that the final breakdown takes place when a water tree penetrates the insulation. In order to reproduce penetrating water trees in a film specimen, a double layer specimen with low-density polyethylene films was subjected to an aging test to generate water trees. After confirming that penetrating water trees had bridged across one layer of the ”double-layer” specimen, the breakdown test was performed with several kinds of combinations of degraded and non-degraded films by applying an AC voltage. It was concluded from the result that the penetrated water tree region would withstand relatively high voltage stresses if the ambient relative humidity was as low as 59 %, however, the breakdown voltage rapidly drops at higher humidities. Finally, it was suggested that, under less humid conditions, a water tree would extend until it bridges across the insulation without causing breakdown, however, the breakdown would likely take place when the ambient humidity turns to be higher. 1. INTRODUCTION Water treeing is one of the major degradation mechanisms in polymeric cable in- sulation. A water tree tends to initiate and extend at the presence of ac field and humid condition. The water tree is an important factor that affects the lifetime of the cable. From the viewpoint of cables’ ”lifetime”, the authors have been carrying out the study on the insulation performances of water tree degraded polyethylene, especially on the breakdown of ”penetrating water tree” that determines the lifetime. A penetrating tree is a kind of water tree that eventually bridges across the insulation. It had been believed that the insulation breaks down as soon as the water tree bridges, since the water tree is generally highly conductive compared to non-tree region. However, many penetrating water trees have been found in field aged cable insulation. This indicates that a cable would withstand the operating voltage for a while even the water tree had bridged across the insulation. This study was conducted to clarify how a penetrated water tree leads to the final breakdown. For this purpose, low-density polyethylene films which contain penetrating water trees were taken as specimens and the effect of humidity on their breakdown charac- teristics was studied. Low-density polyethylene films were provided by Mitsubishi Chemi- cal Co. Ltd and part of experiment was conducted in High Field Phenomenon Laboratory of Toyohashi University of Techmology, Japan. 58 Vu Thanh Hai and Nguyen Dinh Thang 2. EXPERIMENTAL PROCEDURE The polymer employed was a commercial LDPE film with 40 micrometers in thick- ness. The density and crystallinity were 0.918 g/cm3 and 46-47 %, respectively. As shown in Fig. 1, a stacked double layer specimen with 80 µm in thickness was subjected to the aging test to generate water trees. The aging was conducted using a water electrode, the water being saturated with FeSO4, under 1 kVrms, 400 Hz. The upper film had been roughened by sandpaper (#1000) before aging. It was confirmed that the water trees had bridged across the upper film after 72 hours of aging. 400Hz Aluminum Foil Double-layer SpecimenFeSO4 + Water Aluminum Plate non-aged mono-layer as-aged double-layer aged mono-layer combined double-layer Fig. 1. Schematic diagram of aging process 75%. Fig. 2. Sample specimens. 50 Hz Specimen Electrode 0.5 mm Air Gap Needle Electrode Fig. 3. Electrode system for ac breakdown test. Four types of specimens, shown in Fig. 2, were subjected to the breakdown test, i.e., ”non-aged 40 µm mono-layer”, ”as aged 80 µm double-layer”, ”aged 40 µm mono-layer” Final Breakdown on Water Tree Degraded Polymer Insulation 59 and ”combined 80 µm double-layer”. The ”aged 40 µm mono-layer” film is the upper film taken from ”as aged 80 µm double-layer”. The ”combined 80 µm double-layer” film is a stacked combination of the ”aged 40 µm mono-layer” and ”non-aged 40 µm mono-layer” films. The breakdown test was carried out using a ”needle and plane” electrode system in air, which gives almost the same value with intrinsic electric strength of polymeric film [1]. As shown in Fig.3, the specimen was attached on the plane electrode, making a 0.5mm gap between the needle tip and upper surface of the specimen. This electrode system was set in the test cell and the surrounding humidity in measurement was adjusted by the fixed point of humidity saturated water solution [2]. All the breakdown tests were performed applying an ac voltage with a ramp rate of 140 V/s at room temperature. 3. RESULTS AND DISCUSSION Fig.4 shows the breakdown strength of four kinds of specimens at 75 % in ambi- ent relative humidity. It is shown that the breakdown voltage of both two double-layer specimens (”as aged 80 µm ” and ”combined 80 µm ”) is almost equal to that of ”non- aged 40 µm mono-layer” film. This suggests that the upper film of the ”as aged 80 µm double-layer” specimen did not share the applied voltage stress. This suggestion would be supported by the low breakdown strength of ”aged 40 µm mono-layer” film. It is also suggested that only a slight degradation has taken place in the lower film during the aging process. It is therefore supposed that a degraded insulation would break down at a considerably low voltage, since the voltage would be shared only by the non-degraded part. Fig. 4. AC breakdown voltages of four kinds of specimens. Relative humidity: 75%. Fig. 5. Breakdown voltages as function of rela- tive humidity. Specimens with the combinations of aged 40 µm and non-aged 40 µm films. Fig.5 shows the breakdown strength as a function of relative humidity. Each plot is indicated with the average, minimum and maximum values through 10 trials. All types of specimens showed a decrease in breakdown voltage with increasing relative humidity, however, the decline differs type by type. With specimens which contain water trees, a large drop is seen above 59 % relative humidity. The breakdown voltage of ”combined 80 µm double-layer” specimen at 15 % and 30 % in humidity is significantly higher than 60 Vu Thanh Hai and Nguyen Dinh Thang that of ”non-aged 40 µm mono layer” specimen. This indicates that the aged layer with penetrating water trees would share some part of the applied voltage if the condition was less humid. At 59 %, however, the difference from the ”non-aged mono-layer” specimen becomes less significant, suggesting that the shared voltage across the degraded part would be decreasing. At 75 % and 98 %, no difference from the ”non-aged mono-layer” is seen. In these cases, almost all part of the applied voltage would be sustained by the non-degraded part. The same tendency was seen in the “combined 60 µm double-layer” specimen with non-degraded 20 µm film, as shown in Fig. 6. These results point out that the penetrated water tree region can share some voltage under low humidity, but no voltage under humid conditions. Fig. 6. Breakdown voltages as a function of relative humidity. Specimens with aged 40 µm and non-aged 20 µm films. In addition, the breakdown voltage with the “aged 40 µm mono-layer” film shows a large drop above 59 %. This agrees with the result with ”combined 80 µm double layer” specimen that leads to the supposition that the conductivity in penetrated tree rapidly increases with increasing humidity. It is generally believed that humid condition is necessary to grow a water tree. The insulation would breakdown as soon as the water tree had bridged if the aging had been took place under a humid condition. On the contrary, the breakdown would not occur immediately after the bridging if the water tree had grown under less humid condition. Many penetrating water trees, having been found in field aged cables, would there- fore been propagated under relatively low humidity. It is therefore considered that a breakdown in such an insulation would likely take place when the ambient humidity turns to be higher. Considering a cable under the operation, the degraded region would dry out during the on load period due to the heating by the load current. This would make the breakdown less probable to occur. However, the increase in the ambient humidity during the off load period would lead to the introduction of water into the degraded region. The most severe condition would take place at the time of next rising of load current, when the insulation with higher water content was being heated up. The breakdown would therefore tend to take place at the beginning of the on load period. Final Breakdown on Water Tree Degraded Polymer Insulation 61 4. CONCLUSIONS Ac breakdown tests were performed with several kinds of stacked LDPE film spec- imens which contains penetrating water trees. The water tree degraded part does not share the applied voltage stress under humid conditions, however, it does share some part when the ambient relative humidity is as low as 59 %. Under less humid conditions, a water tree would able to extend until it penetrates through the insulation without causing breakdown. The breakdown in such an insulation would likely to take place when the ambient humidity turns to be higher. REFERENCES 1. M. Nagao et.al : ISEIM, (1998) 425-428 2. L. Greenspan, J. Res, National Bureau of Standards-A, Physics and Chemistry, 81A (1) (1977) 89-96 3. T. Tsurimoto et.a.l., Trans. I.E.E. of Japan 115-A (1995)1157-1161 (in Japanese) 4. Vu Hai Thanh et al., Record of 1998 Tokai-Section Joint Conference of the Seven Institutes of Electrical and Related Engineers #. 263 Received December 21, 2005.

File đính kèm:

final_breakdown_on_water_tree_degraded_polymer_insulation.pdf

final_breakdown_on_water_tree_degraded_polymer_insulation.pdf