Effects of packaging materials and disinfectants on quality changes of ceylon spinach (Basella alba L.) during storage

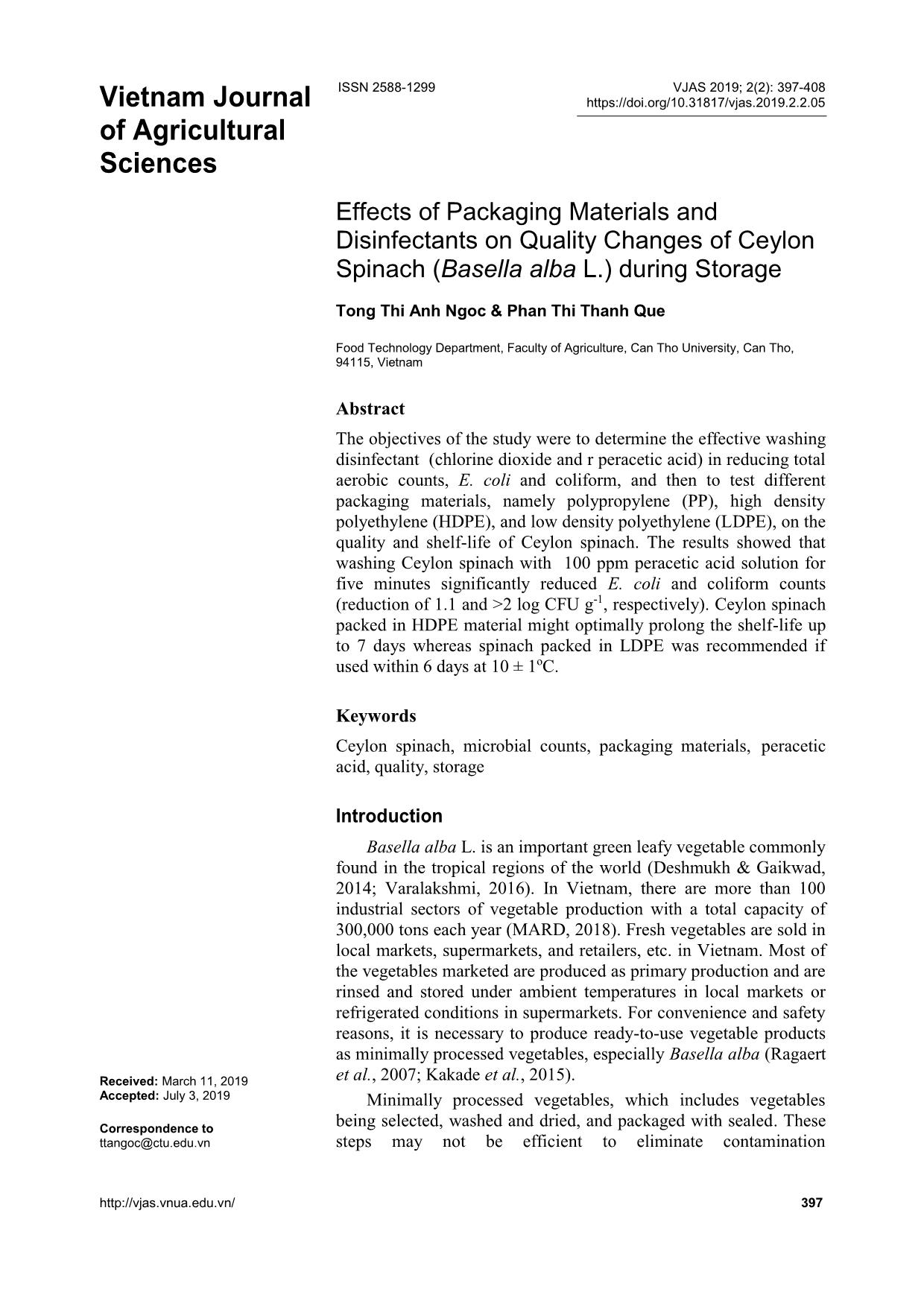

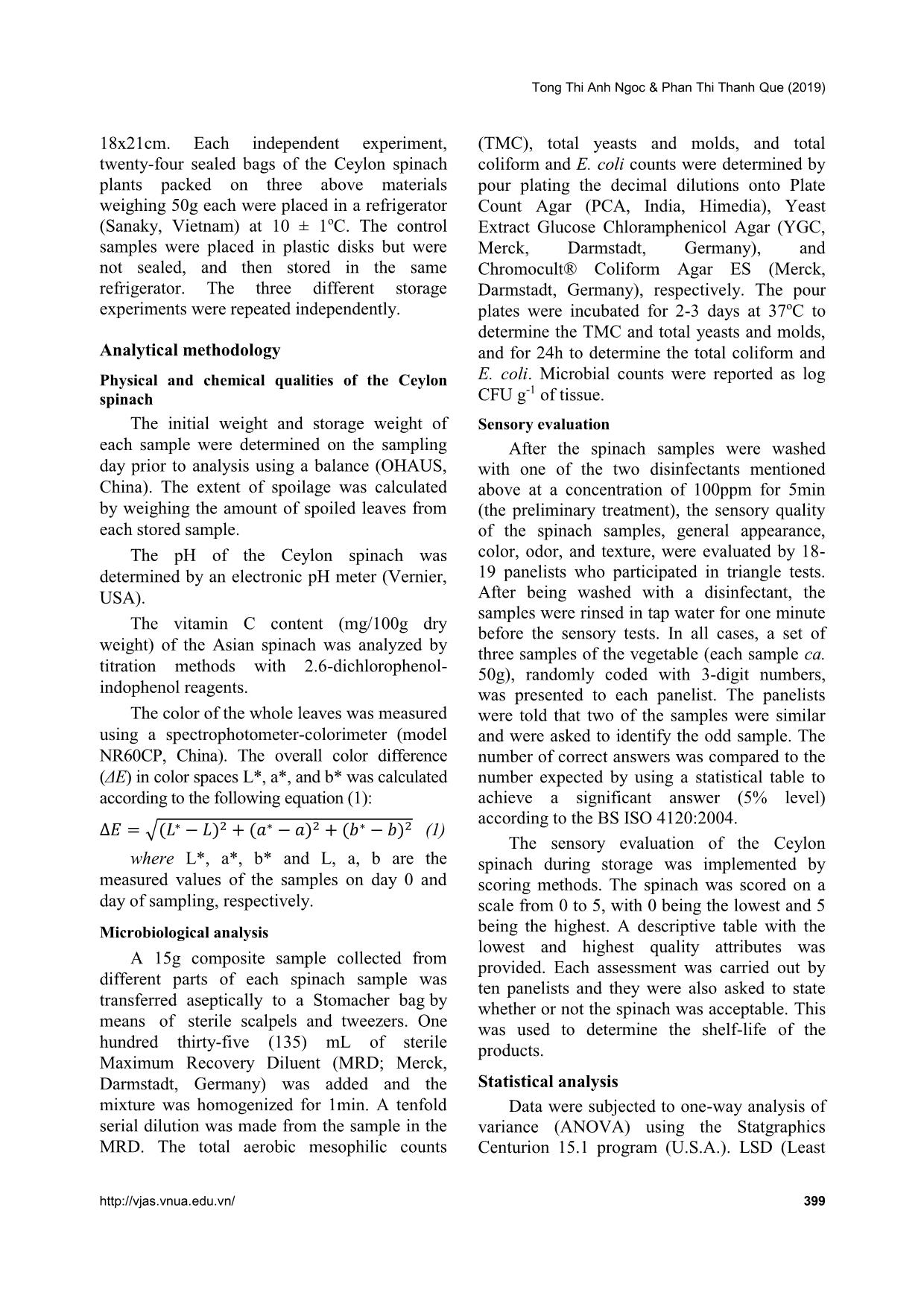

The objectives of the study were to determine the effective washing

disinfectant (chlorine dioxide and r peracetic acid) in reducing total

aerobic counts, E. coli and coliform, and then to test different

packaging materials, namely polypropylene (PP), high density

polyethylene (HDPE), and low density polyethylene (LDPE), on the

quality and shelf-life of Ceylon spinach. The results showed that

washing Ceylon spinach with 100 ppm peracetic acid solution for

five minutes significantly reduced E. coli and coliform counts

(reduction of 1.1 and >2 log CFU g-1, respectively). Ceylon spinach

packed in HDPE material might optimally prolong the shelf-life up

to 7 days whereas spinach packed in LDPE was recommended if

used within 6 days at 10 ± 1oC.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

Tóm tắt nội dung tài liệu: Effects of packaging materials and disinfectants on quality changes of ceylon spinach (Basella alba L.) during storage

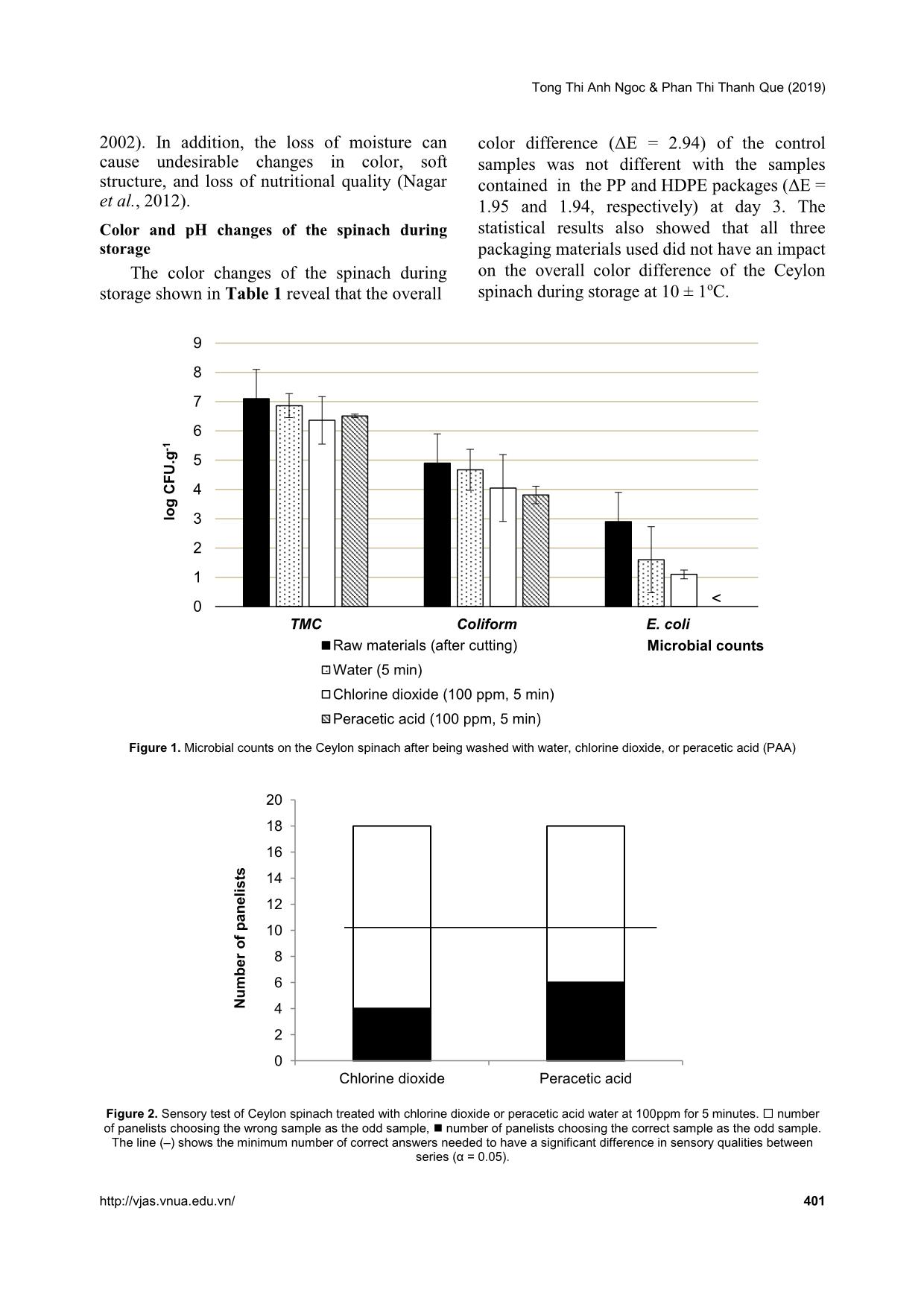

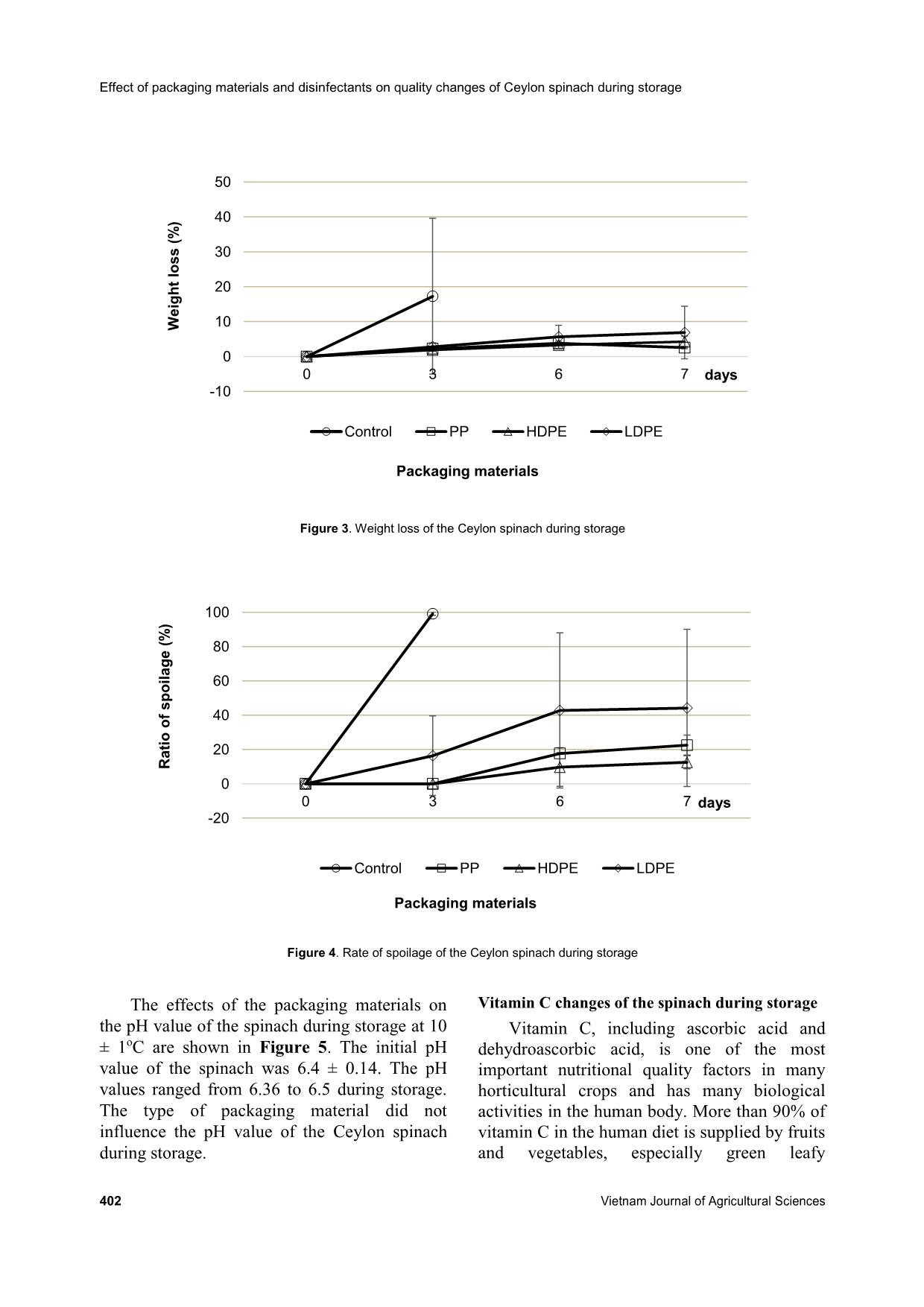

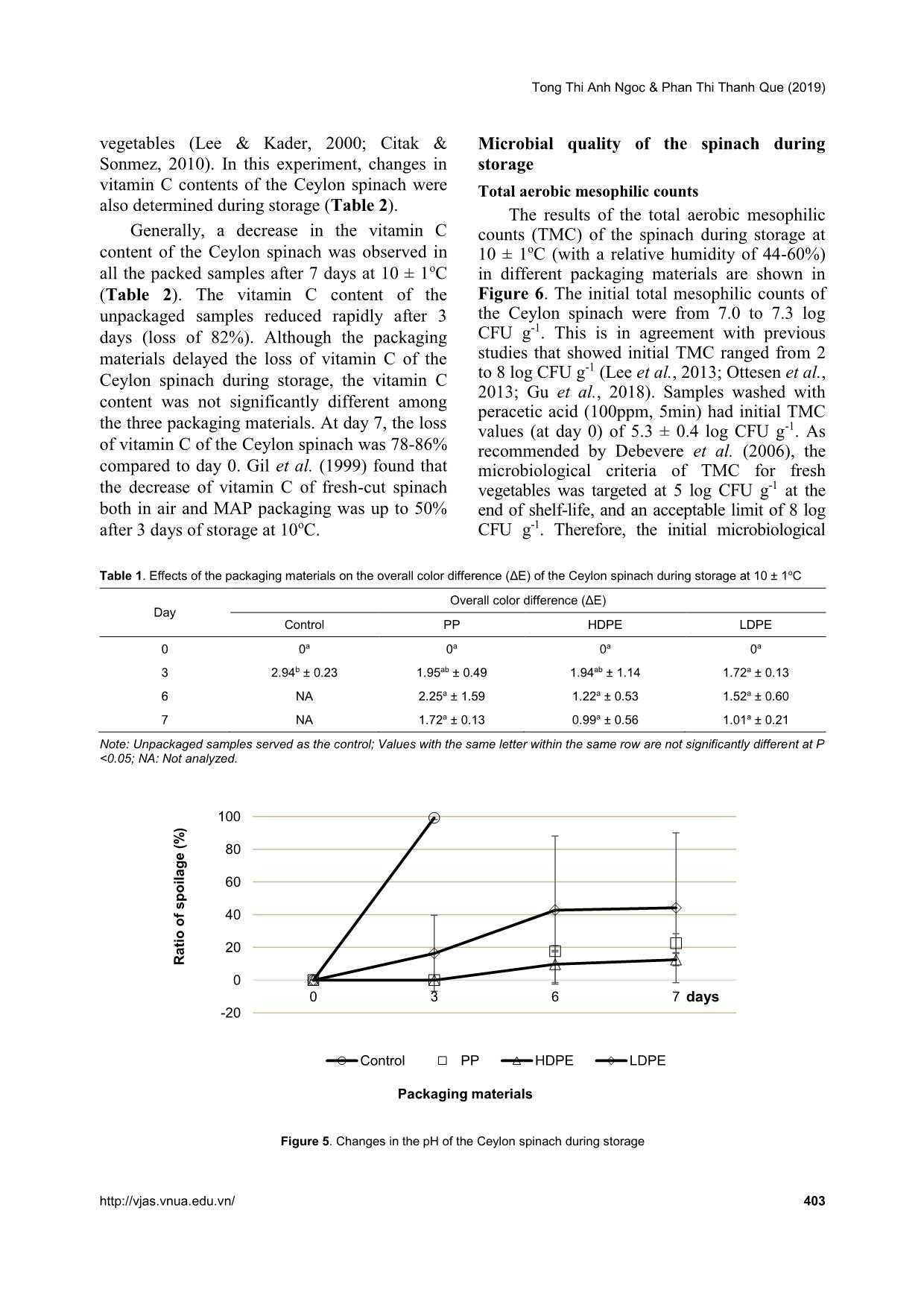

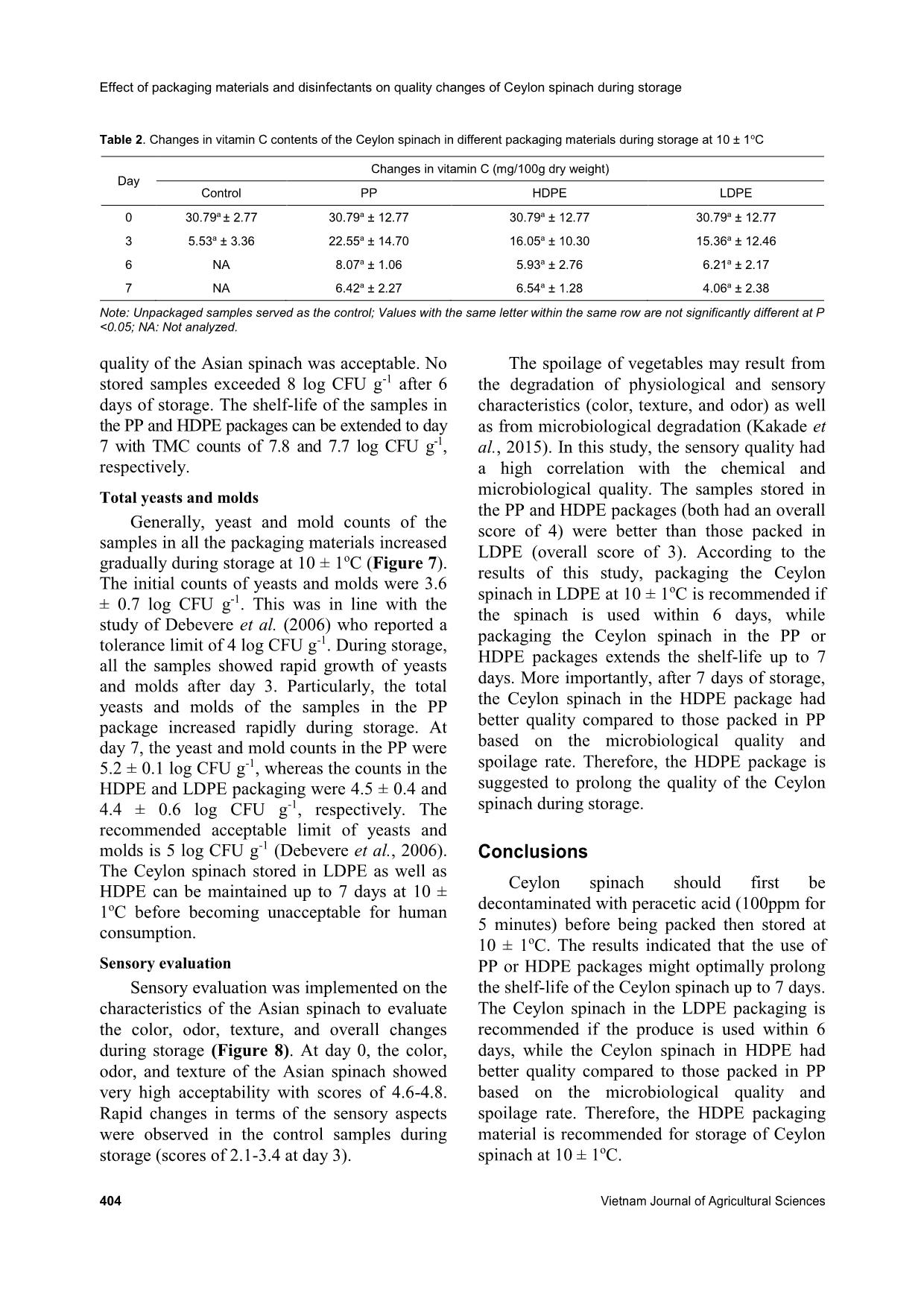

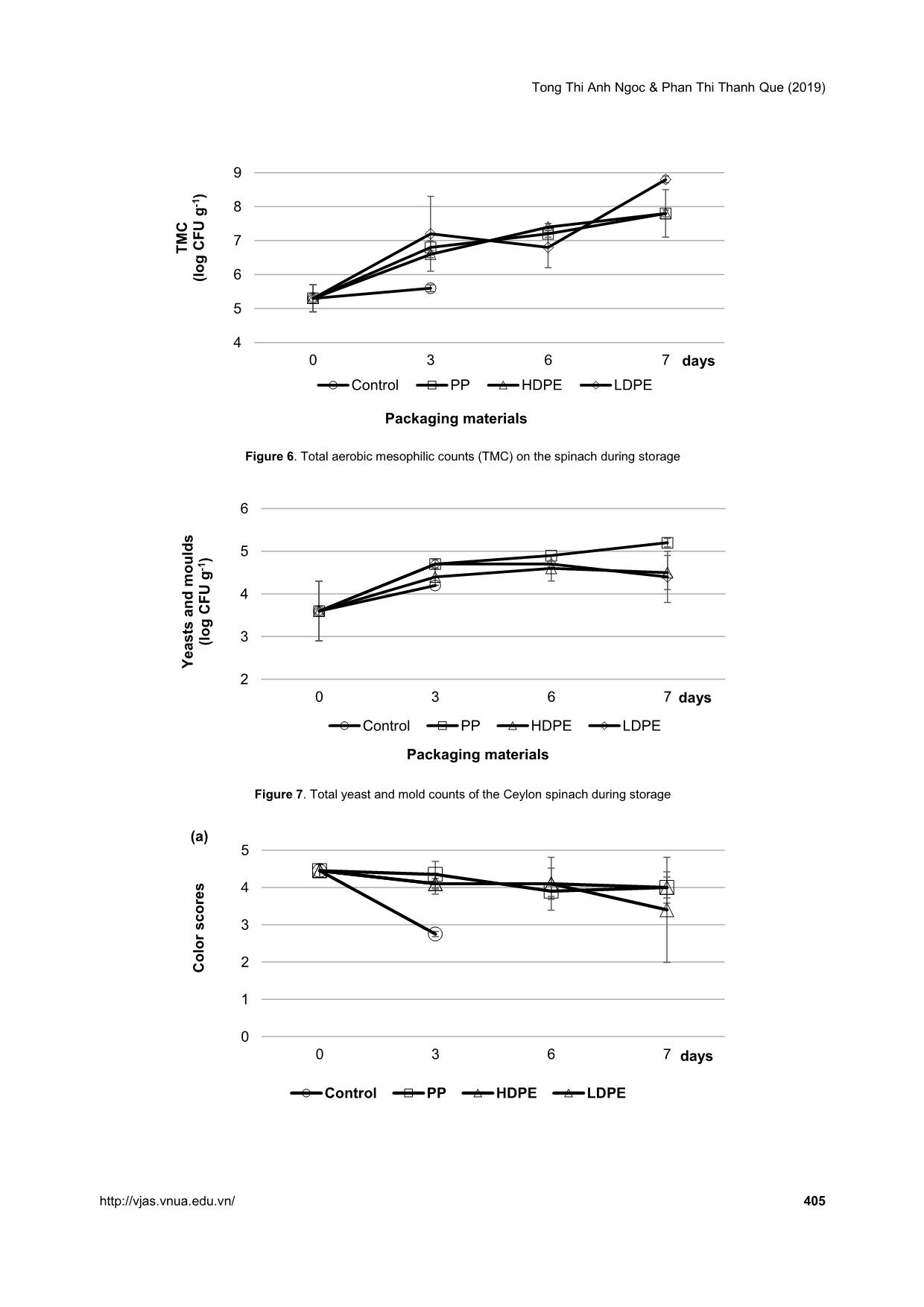

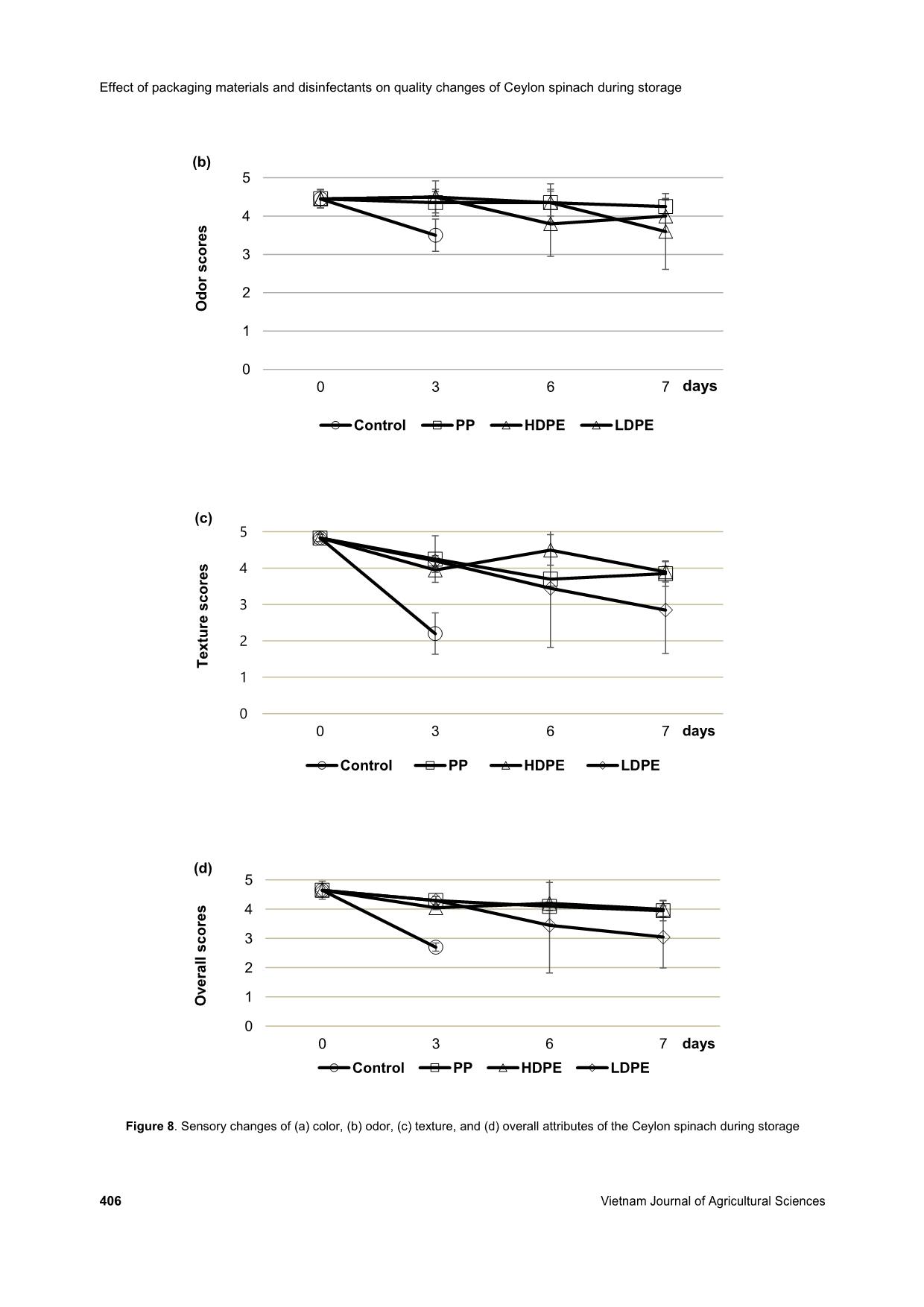

lts of the total aerobic mesophilic counts (TMC) of the spinach during storage at 10 ± 1oC (with a relative humidity of 44-60%) in different packaging materials are shown in Figure 6. The initial total mesophilic counts of the Ceylon spinach were from 7.0 to 7.3 log CFU g-1. This is in agreement with previous studies that showed initial TMC ranged from 2 to 8 log CFU g-1 (Lee et al., 2013; Ottesen et al., 2013; Gu et al., 2018). Samples washed with peracetic acid (100ppm, 5min) had initial TMC values (at day 0) of 5.3 ± 0.4 log CFU g-1. As recommended by Debevere et al. (2006), the microbiological criteria of TMC for fresh vegetables was targeted at 5 log CFU g-1 at the end of shelf-life, and an acceptable limit of 8 log CFU g-1. Therefore, the initial microbiological Table 1. Effects of the packaging materials on the overall color difference (ΔE) of the Ceylon spinach during storage at 10 ± 1oC Day Overall color difference (ΔE) Control PP HDPE LDPE 0 0a 0a 0a 0a 3 2.94b ± 0.23 1.95ab ± 0.49 1.94ab ± 1.14 1.72a ± 0.13 6 NA 2.25a ± 1.59 1.22a ± 0.53 1.52a ± 0.60 7 NA 1.72a ± 0.13 0.99a ± 0.56 1.01a ± 0.21 Note: Unpackaged samples served as the control; Values with the same letter within the same row are not significantly different at P <0.05; NA: Not analyzed. Figure 5. Changes in the pH of the Ceylon spinach during storage -20 0 20 40 60 80 100 0 3 6 7 R a ti o o f s p o il a g e ( % ) Packaging materials Control PP HDPE LDPE days Effect of packaging materials and disinfectants on quality changes of Ceylon spinach during storage 404 Vietnam Journal of Agricultural Sciences Table 2. Changes in vitamin C contents of the Ceylon spinach in different packaging materials during storage at 10 ± 1oC Day Changes in vitamin C (mg/100g dry weight) Control PP HDPE LDPE 0 30.79a ± 2.77 30.79a ± 12.77 30.79a ± 12.77 30.79a ± 12.77 3 5.53a ± 3.36 22.55a ± 14.70 16.05a ± 10.30 15.36a ± 12.46 6 NA 8.07a ± 1.06 5.93a ± 2.76 6.21a ± 2.17 7 NA 6.42a ± 2.27 6.54a ± 1.28 4.06a ± 2.38 Note: Unpackaged samples served as the control; Values with the same letter within the same row are not significantly different at P <0.05; NA: Not analyzed. quality of the Asian spinach was acceptable. No stored samples exceeded 8 log CFU g-1 after 6 days of storage. The shelf-life of the samples in the PP and HDPE packages can be extended to day 7 with TMC counts of 7.8 and 7.7 log CFU g-1, respectively. Total yeasts and molds Generally, yeast and mold counts of the samples in all the packaging materials increased gradually during storage at 10 ± 1oC (Figure 7). The initial counts of yeasts and molds were 3.6 ± 0.7 log CFU g-1. This was in line with the study of Debevere et al. (2006) who reported a tolerance limit of 4 log CFU g-1. During storage, all the samples showed rapid growth of yeasts and molds after day 3. Particularly, the total yeasts and molds of the samples in the PP package increased rapidly during storage. At day 7, the yeast and mold counts in the PP were 5.2 ± 0.1 log CFU g-1, whereas the counts in the HDPE and LDPE packaging were 4.5 ± 0.4 and 4.4 ± 0.6 log CFU g-1, respectively. The recommended acceptable limit of yeasts and molds is 5 log CFU g-1 (Debevere et al., 2006). The Ceylon spinach stored in LDPE as well as HDPE can be maintained up to 7 days at 10 ± 1oC before becoming unacceptable for human consumption. Sensory evaluation Sensory evaluation was implemented on the characteristics of the Asian spinach to evaluate the color, odor, texture, and overall changes during storage (Figure 8). At day 0, the color, odor, and texture of the Asian spinach showed very high acceptability with scores of 4.6-4.8. Rapid changes in terms of the sensory aspects were observed in the control samples during storage (scores of 2.1-3.4 at day 3). The spoilage of vegetables may result from the degradation of physiological and sensory characteristics (color, texture, and odor) as well as from microbiological degradation (Kakade et al., 2015). In this study, the sensory quality had a high correlation with the chemical and microbiological quality. The samples stored in the PP and HDPE packages (both had an overall score of 4) were better than those packed in LDPE (overall score of 3). According to the results of this study, packaging the Ceylon spinach in LDPE at 10 ± 1oC is recommended if the spinach is used within 6 days, while packaging the Ceylon spinach in the PP or HDPE packages extends the shelf-life up to 7 days. More importantly, after 7 days of storage, the Ceylon spinach in the HDPE package had better quality compared to those packed in PP based on the microbiological quality and spoilage rate. Therefore, the HDPE package is suggested to prolong the quality of the Ceylon spinach during storage. Conclusions Ceylon spinach should first be decontaminated with peracetic acid (100ppm for 5 minutes) before being packed then stored at 10 ± 1oC. The results indicated that the use of PP or HDPE packages might optimally prolong the shelf-life of the Ceylon spinach up to 7 days. The Ceylon spinach in the LDPE packaging is recommended if the produce is used within 6 days, while the Ceylon spinach in HDPE had better quality compared to those packed in PP based on the microbiological quality and spoilage rate. Therefore, the HDPE packaging material is recommended for storage of Ceylon spinach at 10 ± 1oC. Tong Thi Anh Ngoc & Phan Thi Thanh Que (2019) 405 Figure 6. Total aerobic mesophilic counts (TMC) on the spinach during storage Figure 7. Total yeast and mold counts of the Ceylon spinach during storage 4 5 6 7 8 9 0 3 6 7 T M C (l o g C F U g -1 ) Packaging materials Control PP HDPE LDPE 2 3 4 5 6 0 3 6 7 Y e a s ts a n d m o u ld s (l o g C F U g -1 ) Packaging materials Control PP HDPE LDPE 0 1 2 3 4 5 0 3 6 7 C o lo r s c o re s days Control PP HDPE LDPE (a) days days Effect of packaging materials and disinfectants on quality changes of Ceylon spinach during storage 406 Vietnam Journal of Agricultural Sciences Figure 8. Sensory changes of (a) color, (b) odor, (c) texture, and (d) overall attributes of the Ceylon spinach during storage 0 1 2 3 4 5 0 3 6 7 O d o r s c o re s days Control PP HDPE LDPE (b) 0 1 2 3 4 5 0 3 6 7 T e x tu re s c o re s days Control PP HDPE LDPE (c) 0 1 2 3 4 5 0 3 6 7 O v e ra ll s c o re s days Control PP HDPE LDPE (d) Tong Thi Anh Ngoc & Phan Thi Thanh Que (2019) 407 Acknowledgements We would like to thank Ms. Pham Hong Nhi and Mr. Dinh Van Khanh Linh for their assistance in this study. References Allende A., Aguayo E. & Artés F. (2004). Microbial and sensory quality of commercial fresh processed red lettuce throughout the production chain and shelf life. International Journal of Food Microbiology. 91: 109- 117. Arturo-Schaan M., Sauvager F., Mamez C., Gougeon A. & Cormier M. (1996). Use of peracetic acid as a disinfectant in a water-treatment plant: effect on the plasmid contents of Escherichia coli strains. Current Microbiology. 32: 43-47. Barbosa L. d. N., Carciofi B. A. M., Dannenhauer C. É. & Monteiro A. R. (2011). Influence of temperature on the respiration rate of minimally processed organic carrots (Daucus Carota L. cv. Brasília). Food Science and Technology. 31: 78-85. Citak S. & Sonmez S. (2010). Effects of conventional and organic fertilization on spinach (Spinacea oleracea L.) growth, yield, vitamin C and nitrate concentration during two successive seasons. Scientia Horticulturae. 126: 415-420. Costa C., Lucera A., Conte A., Mastromatteo M., Speranza B., Antonacci A. & Del Nobile M. (2011). Effects of passive and active modified atmosphere packaging conditions on ready-to-eat table grape. Journal of Food Engineering. 102: 115-121. Debevere J., Uyttendaele M., Devlieghere F. & Jacxsens L. (2006). Microbiological guide values and legal microbiological criteria. Laboratory of Food Microbiology and Food Preservation, Ghent University, Ghent, Belgium. Demirci A. & Ngadi M. O. (2012). Microbial decontamination in the food industry: Novel methods and applications. Elsevier. Deshmukh S. & Gaikwad D. (2014). A review of the taxonomy, ethnobotany, phytochemistry and pharmacology of Basella alba (Basellaceae). Journal of Applied Pharmaceutical Science. 4: 153-165. Gil M. I., Ferreres F. & Tomás-Barberán F. A. (1999). Effect of postharvest storage and processing on the antioxidant constituents (flavonoids and vitamin C) of fresh-cut spinach. Journal of Agricultural and Food Chemistry. 47: 2213-2217. Graça A., Esteves E., Nunes C., Abadias M. & Quintas C. (2017). Microbiological quality and safety of minimally processed fruits in the marketplace of southern Portugal. Food control. 73: 775-783. Gu G., Ottesen A., Bolten S., Ramachandran P., Reed E., Rideout S., Luo Y., Patel J., Brown E. & Nou X. (2018). Shifts in spinach microbial communities after chlorine washing and storage at compliant and abusive temperatures. Food Microbiology. 73: 73-84. Jacobsson A., Nielsen T. & Sjöholm I. (2004). Effects of type of packaging material on shelf-life of fresh broccoli by means of changes in weight, colour and texture. European Food Research and Technology. 218: 157-163. Jin H. H. & Lee S. Y. (2007). Combined effect of aqueous chlorine dioxide and modified atmosphere packaging on inhibiting Salmonella Typhimurium and Listeria monocytogenes in mungbean sprouts. Journal of Food Science. 72: M441-M445. Joshi K., Mahendran R., Alagusundaram K., Norton T. & Tiwari B. (2013). Novel disinfectants for fresh produce. Trends in Food Science & Technology. 34: 54-61. Kakade A., More P., Jadhav S. & Bhosle V. (2015). Shelf life extension of fresh-cut spinach. International Journal of Agriculture, Environment and Biotechnology. 8: 609. Kitis M. (2004). Disinfection of wastewater with peracetic acid: a review. Environment International. 30: 47-55. Kotzekidou P. & Bloukas J. (1996). Effect of protective cultures and packaging film permeability on shelf-life of sliced vacuum-packed cooked ham. Meat Science. 42: 333-345. Lee M., Lee D. Y., Kim M.-D., Won J. Y., Yune Y.-N., Lee T. Y., Choi D. & Ko Y.-G. (2013). Selective coverage of the left subclavian artery without revascularization in patients with bilateral patent vertebrobasilar junctions during thoracic endovascular aortic repair. Journal of Vascular Surgery. 57: 1311-1316. Lee S. K. & Kader A. A. (2000). Preharvest and postharvest factors influencing vitamin C content of horticultural crops. Postharvest Biology and Technology. 20: 207-220. Li Y., Brackett R., Shewfelt R. & Beuchat L. (2001). Changes in appearance and natural microflora on iceberg lettuce treated in warm, chlorinated water and then stored at refrigeration temperature. Food Microbiology. 18: 299-308. Ly Nguyen Binh & Tong Thi Anh Ngoc (2017). Changes in the quality of fresh catfish (Pangasius hypophthalmus) fillets during refrigerated storage under different types of packaging. Proceedings of the 15th Asean Conference on food science and technology. Science and Technics Publishing House Hanoi. Volume 2. 195-201. ISBN: 987-604-67- 10006-6. MARD (2018). Ministry of Agriculture and Rural Development (MARD) (2018). Retrieved from https://www.mard.gov.vn/ThongKe/Lists/BaoCaoTho ngKe/Attachments/132/Baocao_T12_2017.pdf on December 4, 2018. Effect of packaging materials and disinfectants on quality changes of Ceylon spinach during storage 408 Vietnam Journal of Agricultural Sciences Monarca S., Richardso S. D., Feretti D., Grottolo M., Thruston A. D., Zani C., Navazio G., Ragazzo P., Zerbini I. & Alberti A. (2002). Mutagenicity and disinfection by‐products in surface drinking water disinfected with peracetic acid. Environmental Toxicology and Chemistry. 21: 309-318. Muizniece-Brasava S., Ruzaike A., Dukalska L., Stokmane I. & Strauta L. (2013). Quality evaluation of ready to eat potatoes’ produce in flexible packaging. International Journal of Biological, Veterinary, Agricultural and Food Engineering. 7: 391-396. Nagar V., Hajare S. N., Saroj S. D. & Bandekar J. R. (2012). Radiation processing of minimally processed sprouts (dew gram and chick pea): effect on sensory, nutritional and microbiological quality. International Journal of Food Science and Technology. 47: 620- 626. Ottesen A. R., Peña A. G., White J. R., Pettengill J. B., Li C., Allard S., Rideout S., Allard M., Hill T. & Evans P. (2013). Baseline survey of the anatomical microbial ecology of an important food plant: Solanum lycopersicum (tomato). BMC Microbiology. 13: 114. Piagentini A. & Güemes D. (2002). Shelf life of fresh-cut spinach as affected by chemical treatment and type of packaging film. Brazilian Journal of Chemical Engineering. 19: 383-389. Ragaert P., Devlieghere F. & Debevere J. (2007). Role of microbiological and physiological spoilage mechanisms during storage of minimally processed vegetables. Postharvest Biology and Technology. 44: 185-194. Sapers G. M. (2001). Efficacy of washing and sanitizing methods for disinfection of fresh fruit and vegetable products. Food Technology and Biotechnology. 39: 305-311. Silveira A., Conesa A., Aguayo E. & Artes F. (2008). Alternative sanitizers to chlorine for use on fresh‐cut “Galia” (Cucumis melo var. catalupensis) melon. Journal of Food Science. 73: 405-411. Suryawanshi M. (2008). Minimal processing and packaging studies in potato. UAS, Dharwad. Tong Thi A. N. (2015). Microbial quality of frozen Pangasius hypophthalmus as influenced by industrial processing in Vietnam. Ghent University. Faculty of Bioscience Engineering, Ghent, Belgium. Tong Thi A. N., Sampers I., Van Haute S., Samapundo S., Nguyen B. L., Heyndrickx M. & Devlieghere F. (2015). Decontamination of Pangasius fish (Pangasius hypophthalmus) with chlorine or peracetic acid in the laboratory and in a Vietnamese processing company. International Journal of Food Microbiology. 208: 93-101. Tong Thi Anh Ngoc, Nguyen Cam Tu, Pham Hong Nhi & Phan Thi Thanh Que (2018). Evaluation of disinfection efficacy of chlorine dioxide and peracetic acid solutions on decontamination of Ceylon spinach (Basella alba). Journal of Agriculture and Rural Development, August 2018. 206-213 (in Vietnamese). Varalakshmi B. (2016). Genetic variability in Indian spinach (Basella alba L.). Journal of Horticultural Science. 5: 21-24.

File đính kèm:

effects_of_packaging_materials_and_disinfectants_on_quality.pdf

effects_of_packaging_materials_and_disinfectants_on_quality.pdf