Effect of temperature and residence time on pyrolysis of rice husk pellet

Biomass, mainly agricultural residues, is found widely available in Vietnam for energy

services. For these ends, it is normally upgraded by thermo-chemical or biological conversions before

being use as clean and efficient fuels. In this work, a pyrolysis of rice husk pellet was performed by mean

of an electrical oven. Three final temperature values were selected i.e 4000C, 6000C, and 8000C. For each

selected value of pyrolysis temperature, three levels of residence time for pyrolysis process were set as

0, 60 and 120 minutes, respectively. Some properties of the final product from the pyrolysis process i.e

volatile, ash content, fixed-carbon and higher heating value (HHV) were measured. The experimental

results have shown that in the current range of experimental work, charcoal products could get the highest

fixed-carbon content at the pyrolysis temperature of 6000C and with the residence time of 120 minutes.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Tóm tắt nội dung tài liệu: Effect of temperature and residence time on pyrolysis of rice husk pellet

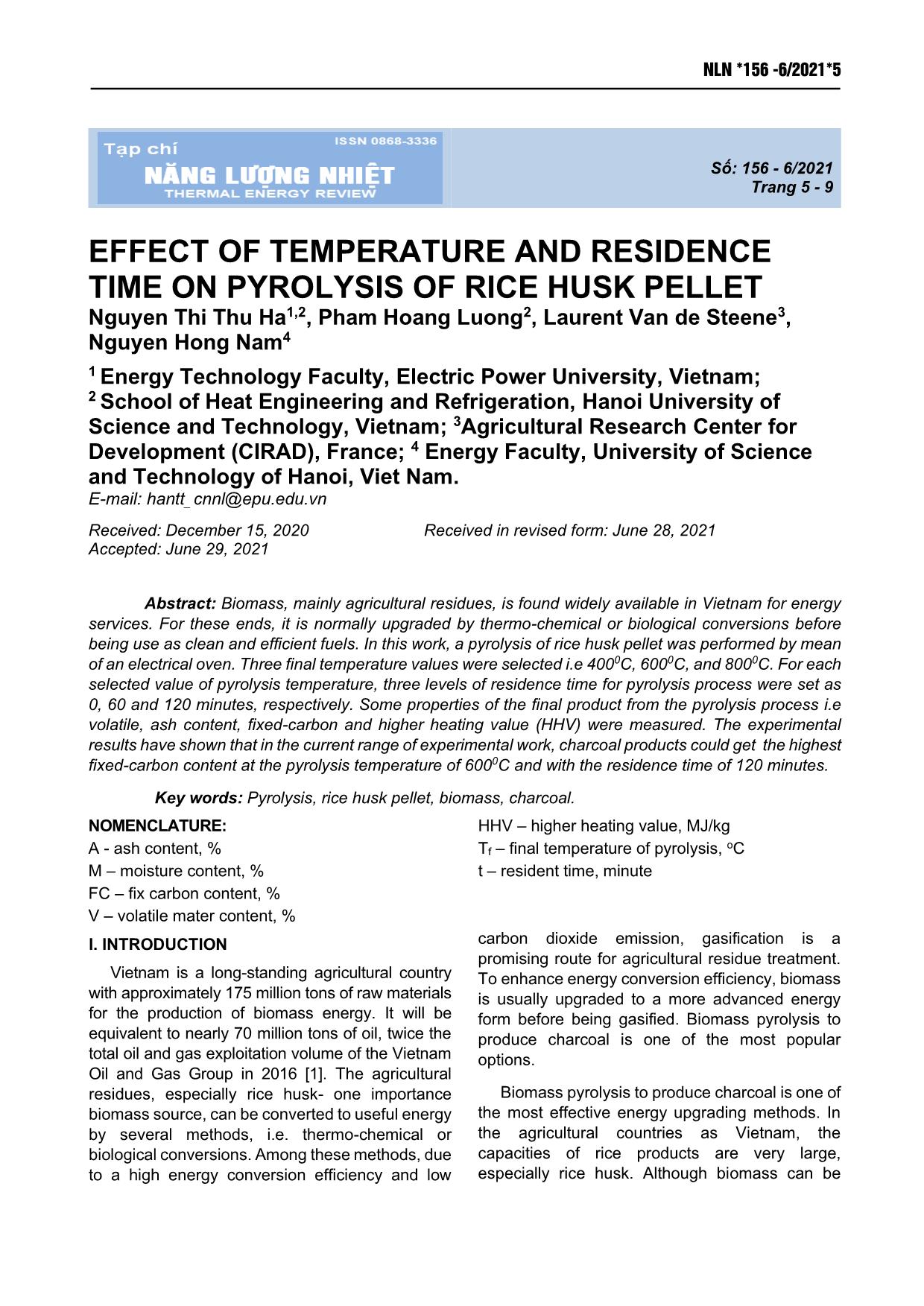

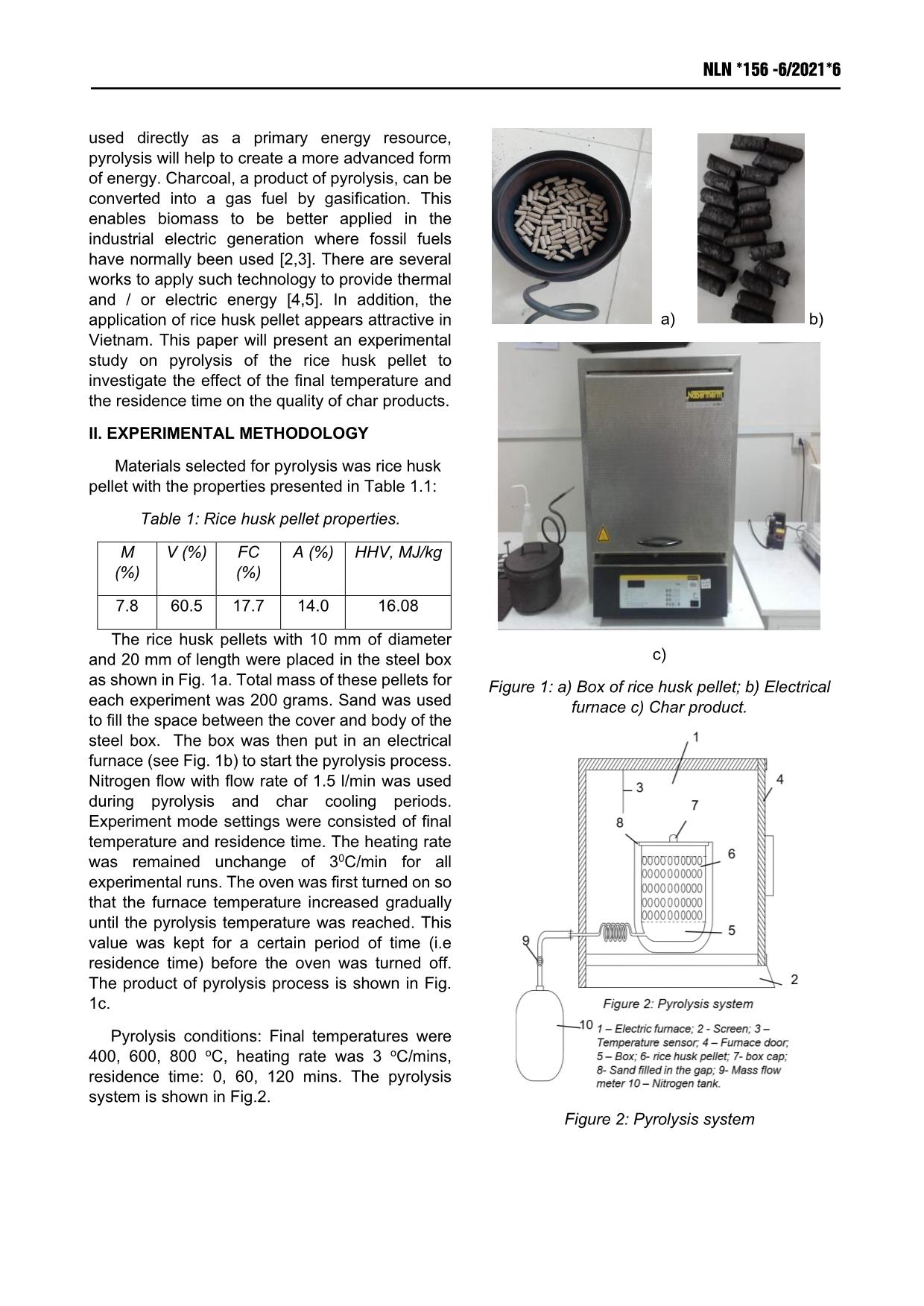

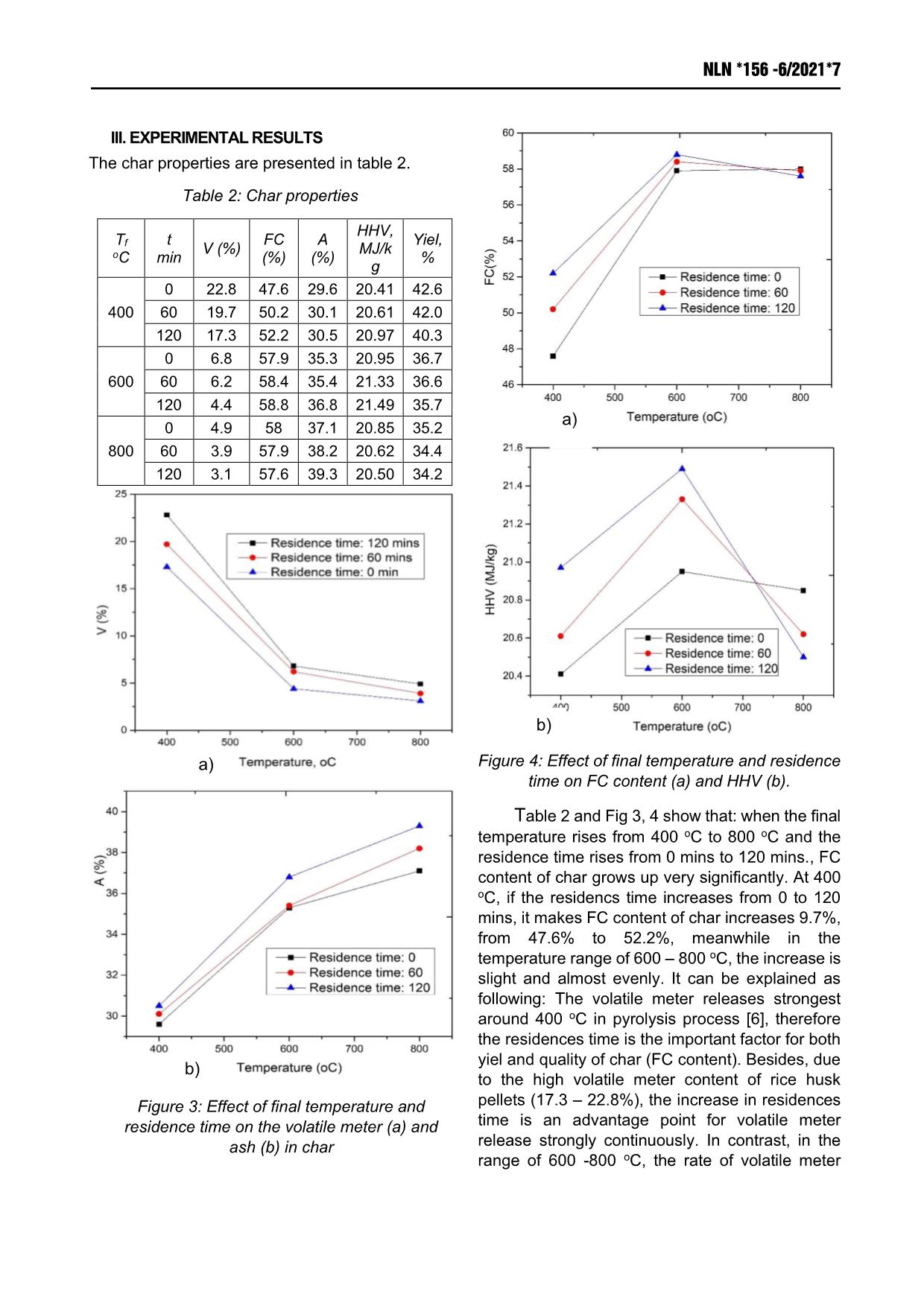

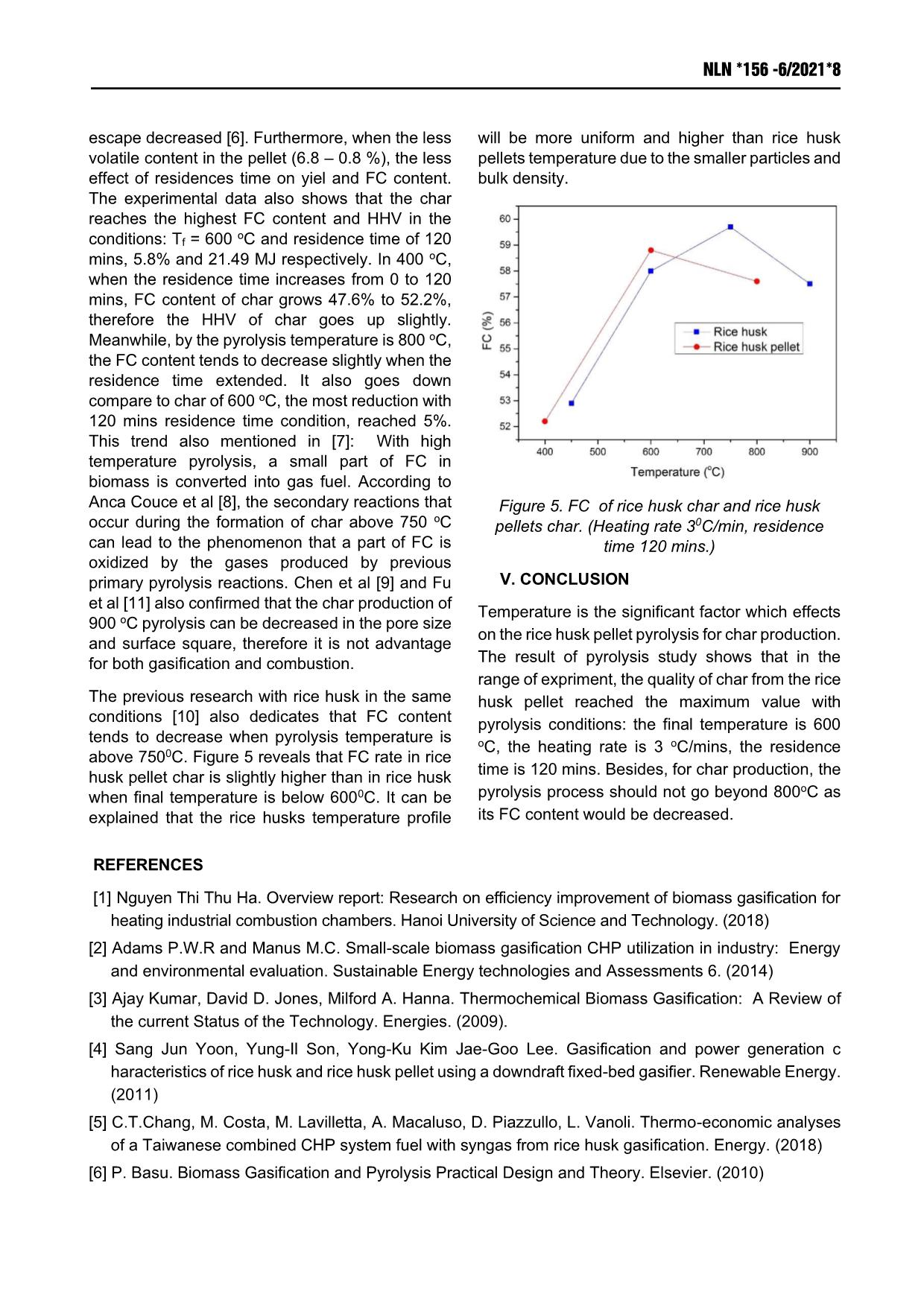

NLN *156 -6/2021*5 Số: 156 - 6/2021 Trang 5 - 9 EFFECT OF TEMPERATURE AND RESIDENCE TIME ON PYROLYSIS OF RICE HUSK PELLET Nguyen Thi Thu Ha1,2, Pham Hoang Luong2, Laurent Van de Steene3, Nguyen Hong Nam4 1 Energy Technology Faculty, Electric Power University, Vietnam; 2 School of Heat Engineering and Refrigeration, Hanoi University of Science and Technology, Vietnam; 3Agricultural Research Center for Development (CIRAD), France; 4 Energy Faculty, University of Science and Technology of Hanoi, Viet Nam. E-mail: hantt_ cnnl@epu.edu.vn Received: December 15, 2020 Received in revised form: June 28, 2021 Accepted: June 29, 2021 Abstract: Biomass, mainly agricultural residues, is found widely available in Vietnam for energy services. For these ends, it is normally upgraded by thermo-chemical or biological conversions before being use as clean and efficient fuels. In this work, a pyrolysis of rice husk pellet was performed by mean of an electrical oven. Three final temperature values were selected i.e 4000C, 6000C, and 8000C. For each selected value of pyrolysis temperature, three levels of residence time for pyrolysis process were set as 0, 60 and 120 minutes, respectively. Some properties of the final product from the pyrolysis process i.e volatile, ash content, fixed-carbon and higher heating value (HHV) were measured. The experimental results have shown that in the current range of experimental work, charcoal products could get the highest fixed-carbon content at the pyrolysis temperature of 6000C and with the residence time of 120 minutes. Key words: Pyrolysis, rice husk pellet, biomass, charcoal. NOMENCLATURE: HHV – higher heating value, MJ/kg o A - ash content, % Tf – final temperature of pyrolysis, C M – moisture content, % t – resident time, minute FC – fix carbon content, % V – volatile mater content, % I. INTRODUCTION carbon dioxide emission, gasification is a promising route for agricultural residue treatment. Vietnam is a long-standing agricultural country To enhance energy conversion efficiency, biomass with approximately 175 million tons of raw materials is usually upgraded to a more advanced energy for the production of biomass energy. It will be form before being gasified. Biomass pyrolysis to equivalent to nearly 70 million tons of oil, twice the produce charcoal is one of the most popular total oil and gas exploitation volume of the Vietnam options. Oil and Gas Group in 2016 [1]. The agricultural residues, especially rice husk- one importance Biomass pyrolysis to produce charcoal is one of biomass source, can be converted to useful energy the most effective energy upgrading methods. In by several methods, i.e. thermo-chemical or the agricultural countries as Vietnam, the biological conversions. Among these methods, due capacities of rice products are very large, to a high energy conversion efficiency and low especially rice husk. Although biomass can be NLN *156 -6/2021*6 used directly as a primary energy resource, pyrolysis will help to create a more advanced form of energy. Charcoal, a product of pyrolysis, can be converted into a gas fuel by gasification. This enables biomass to be better applied in the industrial electric generation where fossil fuels have normally been used [2,3]. There are several works to apply such technology to provide thermal and / or electric energy [4,5]. In addition, the application of rice husk pellet appears attractive in a) b) Vietnam. This paper will present an experimental study on pyrolysis of the rice husk pellet to investigate the effect of the final temperature and the residence time on the quality of char products. II. EXPERIMENTAL METHODOLOGY Materials selected for pyrolysis was rice husk pellet with the properties presented in Table 1.1: Table 1: Rice husk pellet properties. M V (%) FC A (%) HHV, MJ/kg (%) (%) 7.8 60.5 17.7 14.0 16.08 The rice husk pellets with 10 mm of diameter and 20 mm of length were placed in the steel box c) as shown in Fig. 1a. Total mass of these pellets for Figure 1: a) Box of rice husk pellet; b) Electrical each experiment was 200 grams. Sand was used furnace c) Char product. to fill the space between the cover and body of the steel box. The box was then put in an electrical furnace (see Fig. 1b) to start the pyrolysis process. Nitrogen flow with flow rate of 1.5 l/min was used during pyrolysis and char cooling periods. Experiment mode settings were consisted of final temperature and residence time. The heating rate was remained unchange of 30C/min for all experimental runs. The oven was first turned on so that the furnace temperature increased gradually until the pyrolysis temperature was reached. This value was kept for a certain period of time (i.e residence time) before the oven was turned off. The product of pyrolysis process is shown in Fig. 1c. Pyrolysis conditions: Final temperatures were 400, 600, 800 oC, heating rate was 3 oC/mins, residence time: 0, 60, 120 mins. The pyrolysis system is shown in Fig.2. Figure 2: Pyrolysis system NLN *156 -6/2021*7 III. EXPERIMENTAL RESULTS The char properties are presented in table 2. Table 2: Char properties HHV, T t FC A Yiel, f V (%) MJ/k oC min (%) (%) % g 0 22.8 47.6 29.6 20.41 42.6 400 60 19.7 50.2 30.1 20.61 42.0 120 17.3 52.2 30.5 20.97 40.3 0 6.8 57.9 35.3 20.95 36.7 600 60 6.2 58.4 35.4 21.33 36.6 120 4.4 58.8 36.8 21.49 35.7 a) 0 4.9 58 37.1 20.85 35.2 800 60 3.9 57.9 38.2 20.62 34.4 120 3.1 57.6 39.3 20.50 34.2 b) Figure 4: Effect of final temperature and residence a) time on FC content (a) and HHV (b). Table 2 and Fig 3, 4 show that: when the final temperature rises from 400 oC to 800 oC and the residence time rises from 0 mins to 120 mins., FC content of char grows up very significantly. At 400 oC, if the residencs time increases from 0 to 120 mins, it makes FC content of char increases 9.7%, from 47.6% to 52.2%, meanwhile in the temperature range of 600 – 800 oC, the increase is slight and almost evenly. It can be explained as following: The volatile meter releases strongest around 400 oC in pyrolysis process [6], therefore the residences time is the important factor for both yiel and quality of char (FC content). Besides, due b) to the high volatile meter content of rice husk Figure 3: Effect of final temperature and pellets (17.3 – 22.8%), the increase in residences residence time on the volatile meter (a) and time is an advantage point for volatile meter ash (b) in char release strongly continuously. In contrast, in the range of 600 -800 oC, the rate of volatile meter NLN *156 -6/2021*8 escape decreased [6]. Furthermore, when the less will be more uniform and higher than rice husk volatile content in the pellet (6.8 – 0.8 %), the less pellets temperature due to the smaller particles and effect of residences time on yiel and FC content. bulk density. The experimental data also shows that the char reaches the highest FC content and HHV in the o conditions: Tf = 600 C and residence time of 120 mins, 5.8% and 21.49 MJ respectively. In 400 oC, when the residence time increases from 0 to 120 mins, FC content of char grows 47.6% to 52.2%, therefore the HHV of char goes up slightly. Meanwhile, by the pyrolysis temperature is 800 oC, the FC content tends to decrease slightly when the residence time extended. It also goes down compare to char of 600 oC, the most reduction with 120 mins residence time condition, reached 5%. This trend also mentioned in [7]: With high temperature pyrolysis, a small part of FC in biomass is converted into gas fuel. According to Anca Couce et al [8], the secondary reactions that Figure 5. FC of rice husk char and rice husk occur during the formation of char above 750 oC pellets char. (Heating rate 30C/min, residence can lead to the phenomenon that a part of FC is time 120 mins.) oxidized by the gases produced by previous primary pyrolysis reactions. Chen et al [9] and Fu V. CONCLUSION et al [11] also confirmed that the char production of Temperature is the significant factor which effects 900 oC pyrolysis can be decreased in the pore size on the rice husk pellet pyrolysis for char production. and surface square, therefore it is not advantage for both gasification and combustion. The result of pyrolysis study shows that in the range of expriment, the quality of char from the rice The previous research with rice husk in the same husk pellet reached the maximum value with conditions [10] also dedicates that FC content pyrolysis conditions: the final temperature is 600 tends to decrease when pyrolysis temperature is oC, the heating rate is 3 oC/mins, the residence above 7500C. Figure 5 reveals that FC rate in rice husk pellet char is slightly higher than in rice husk time is 120 mins. Besides, for char production, the o when final temperature is below 6000C. It can be pyrolysis process should not go beyond 800 C as explained that the rice husks temperature profile its FC content would be decreased. REFERENCES [1] Nguyen Thi Thu Ha. Overview report: Research on efficiency improvement of biomass gasification for heating industrial combustion chambers. Hanoi University of Science and Technology. (2018) [2] Adams P.W.R and Manus M.C. Small-scale biomass gasification CHP utilization in industry: Energy and environmental evaluation. Sustainable Energy technologies and Assessments 6. (2014) [3] Ajay Kumar, David D. Jones, Milford A. Hanna. Thermochemical Biomass Gasification: A Review of the current Status of the Technology. Energies. (2009). [4] Sang Jun Yoon, Yung-Il Son, Yong-Ku Kim Jae-Goo Lee. Gasification and power generation c haracteristics of rice husk and rice husk pellet using a downdraft fixed-bed gasifier. Renewable Energy. (2011) [5] C.T.Chang, M. Costa, M. Lavilletta, A. Macaluso, D. Piazzullo, L. Vanoli. Thermo-economic analyses of a Taiwanese combined CHP system fuel with syngas from rice husk gasification. Energy. (2018) [6] P. Basu. Biomass Gasification and Pyrolysis Practical Design and Theory. Elsevier. (2010) NLN *156 -6/2021*9 [7] Hoang-Luong Pham. Wood Energy Basics: A Technical Document, Regional Wood Energy Development Program of Food and Agriculture Organization. FAO/RWEDP, Bangkok, Thailand, (1999) [8] Anca-Couce Andrés, Alba Dieguez- Alonso, Nico Zobel, Anka Berger, Norbert Kienzl and Frank Behrendt. Influence of heterogerous secondary reactions during slow pyrolysis on char oxidation reactivity of woody biomass. Energy&Fuel. (2017) [9] Dengyu Chen, Yanjun Li, Kehui Cen, Min Luo, Hongyan Li and Bin Lu. Pyrolysis poly generation of poplar wood: Effect of heating rate and pyrolysis temperaturE. Bio resource Technology. (2016) [10] Nguyen Thi Thu Ha, Pham Hoang Luong. Effect of temperature and heating rate in rice husk pyrolysis process for char coal production. Thermal Energy review. (2018) [11] Peng Fu, Song Hu, Jun Xiang, Lushi Sun, Sheng Su and Jing Wang. Evaluation of the porous structure development of chars from pyrolysis of rice straw: Effect of pyrolysis temperature and heating rate. Journal of analytical and applied pyrolysis. (2012) ẢNH HƯỞNG CỦA NHIỆT ĐỘ VÀ THỜI GIAN NHIỆT PHÂN ĐẾN CHẤT LƯỢNG NHIỆT PHÂN CỦA VIÊN NÉN TRẤU Nguyễn Thị Thu Hà1,2, Phạm Hoàng Lương2, Laurent Van de Steene3, Nguyễn Hồng Nam4 1 Khoa Công nghệ năng lượng, Đại học điện lực, Việt Nam 2 Viện Khoa học và Công nghệ Nhiệt-Lạnh, Đại học Bách Khoa Hà Nội 3Trung tâm nghiên cứu quốc tế về nông nghiệp (CIRAD), Cộng hòa Pháp 4 Khoa Năng lượng, Đại học Khoa học và Công nghệ Hà Nội, Việt Nam E-mail: hantt_ cnnl@epu.edu.vn TÓM TẮT Sinh khối, chủ yếu là phụ phẩm nông nghiệp, được sử dụng rộng rãi ở Việt Nam như một nguồn năng lượng năng lượng. Đối với mục tiêu cấp nhiệt, sinh khối thường được nâng cấp bằng cách chuyển đổi nhiệt hóa học hoặc sinh học trước khi được sử dụng làm nhiên liệu sạch và hiệu quả. Trong công trình này, quá trình nhiệt phân viên trấu được thực hiện bằng lò điện. Ba giá trị nhiệt độ cuối cùng được chọn là 4000C, 6000C và 8000C. Đối với mỗi giá trị của nhiệt độ nhất định, 3 mức thời gian lưu trú cho quá trình nhiệt phân được đặt lần lượt là 0, 60 và 120 phút. Một số đặc tính của sản phẩm cuối cùng từ các quá trình nhiệt phân này, tức là chất bốc, hàm lượng tro, cacbon cố định và giá trị gia nhiệt cao (HHV) đã được xác định. Kết quả thí nghiệm cho thấy trong phạm vi thí nghiệm, sản phẩm than hoa đạt hàm lượng cacbon cố định cao nhất ở nhiệt độ 6000C với thời gian nhiệt phân là 120 phút.

File đính kèm:

effect_of_temperature_and_residence_time_on_pyrolysis_of_ric.pdf

effect_of_temperature_and_residence_time_on_pyrolysis_of_ric.pdf