Designing hedge algebraic controller and optimizing by genetic algorithm for serial robots adhering trajectories

In recent years, the application of hedge algebras in the field of control has been studied.

The results show that this approach has many advantages. In addition, industrial robots are being

well-developed and extensively used, especially in the industrial revolution 4.0. Accurate control of

industrial robots is a class of problems that many scientists are interested in. In this paper, we design

a controller based on hedge algebras for serial robots. The control rule is given by the linguistic

rule-based system. The goal is to accurately control the moving robot arm which adheres given

trajectories. Optimization of fuzzy parameters for the controller is done by genetic algorithms. The

system has been simulated on the Matlab-Simulink software. The simulation results show that the

tracking error is very small. Moreover, the controller worked well with correct control quality. This

result once presents the simplicity and efficiency of the hedge algebras approach to control.

Trang 1

Trang 2

Trang 3

Trang 4

Trang 5

Trang 6

Trang 7

Trang 8

Trang 9

Trang 10

Tải về để xem bản đầy đủ

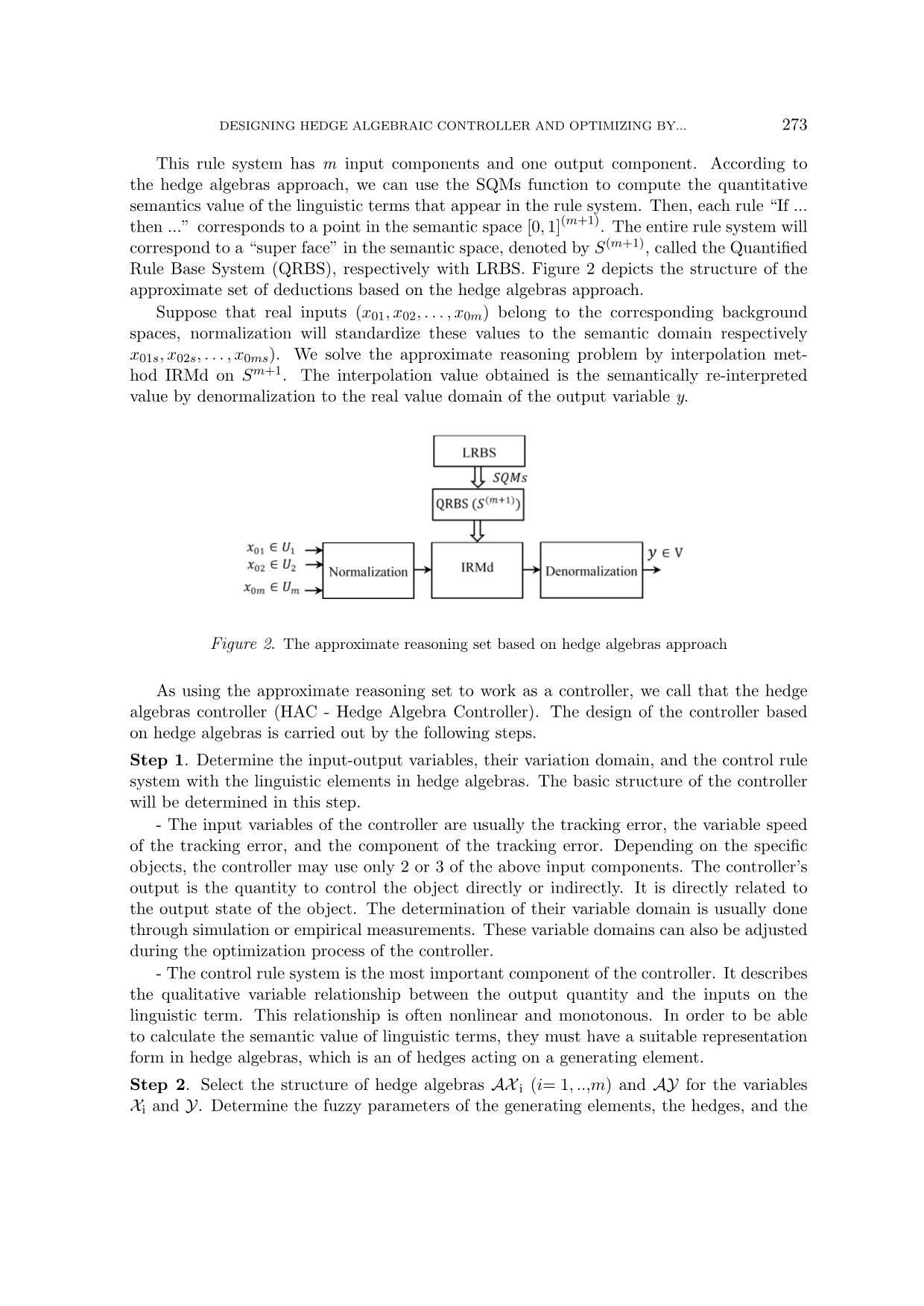

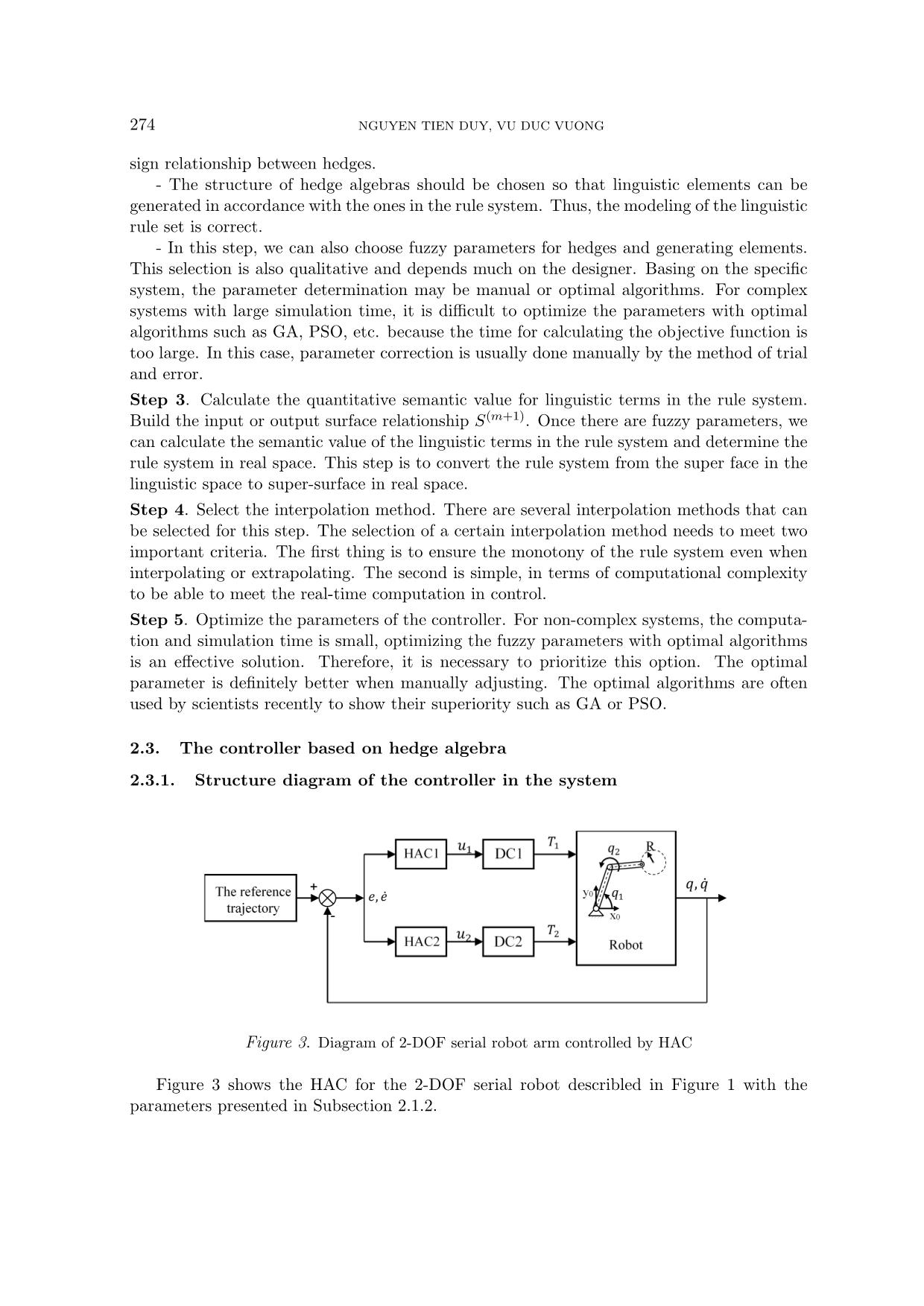

Tóm tắt nội dung tài liệu: Designing hedge algebraic controller and optimizing by genetic algorithm for serial robots adhering trajectories

gn relationship as shown in Table 2. Table 2. The sign relationship of hedges and generating elements V L N P V + + − + L − − + − Interpolation based on the Semantic Distance Weighting method (ISDMd) is selected as in [28]. This is a linear interpolation method that allows interpolation in n-dimensional space. It ensures the systematic monotony in case of interpolation/extrapolation and needs a small number of calculations that meets the requirements of real-time control of the system. 3. OPTIMIZATION OF PARAMETERS BY GENETIC SOLUTION The genetic algorithm is a method of optimal random search that follows the evolution and selection of biological populations in nature [29]. Operations in algorithm-based evo- lution include crossover, mutation, and selection. Each individual is expressed simply as a chromosome consisting of multiple gene segments. Each gene segment is encoded for an optimal parameter. Then each individual is a solution of the problem with an optimal set of parameters. After an evolutionary process (repetition) is large enough, individuals will gradually adapt to the adaptive conditions evaluated by the fitness function. The fuzziness parameters need to be optimized for the controller. For fuzzy controllers, the variable domain of the input and output is usually symmetric. When expressing the value on this domain in language, the rank of Zero (ZE) has semantics that refers to the real value of 0. This is the element corresponding to the neutral element W of hedge algebra, v(W ) = θ. When mapping all linguistic values to the semantic domain in the range [0, 1], semantic value (ZE) = 0.5. Therefore, according to (19), we choose fixed variables of values fm (N) = v(ZE) = 0.5. The set of hedges in hedge algebras is built with only 2 hedges, V (Very) and L (Little), so we only need to optimize µ (L) =α (because of µ (V ) =β= 1−α). So we only need to optimize 3 parameters αe, αce and αu corresponding to 3 variables e, ce, and u. The objective function is chosen according to the absolute value integration standard of the tracking error (IAE) fitness = n∑ k=1 |e (k)| → min (27) where, e(k) is the sample of deviation data at the simulation cycle k, n is the total number of data samples of a simulation run. In Matlab, GA is an available tool that allows us to easily use it. In this study, we use the GA() function in Matlab with gene encoding using real numbers of type double. The values set for GA include: 278 NGUYEN TIEN DUY, VU DUC VUONG • Population size: Population Size = 100; • The number of Generation: Generation = 4*Population Size; • Maximum limit for searching time: Time Limit = 86400, (24 hours); • The target function is used as in formula (27). Results are the optimal parameters set for the controller as shown in Table 3. Table 3. The optimal parameters of HAC based on GA AX e : αe = µ(Le) AX ce : αce = µ(Lce) AY : αu = µ(Lu) 0.520936 0.508062 0.499074 Figure 5. Surface of input/output relationship S3 of optimal HAC With optimal fuzziness parameters found in Table 3, the SQMs function (19) - (22) is used to calculate the semantic value of the elements in LRBS in Table 1, we obtain QRBS and the surface S3 of HAC correspondingly. Figure 5 is an input-output relationship of the rule based system corresponding to the optimal QRBS. 4. SIMULATION RESULTS AND DISCUSSION The diagram simulating the control system of 2-DOF serial robot with HAC on the Matlab-Simulink environment as shown in Figure 6. In the simulation diagram, we use 2 sets of HAC with common parameter sets to control for 2 motors with the same parameters. The control program code is written as Level-2 M-file S-Function. Blocks DC1 and DC2 are mathematical representations for brushless DC motors. These selected motor are the same. The “Robot” block calculates the inverse dynamics problem. “Trajectory” is a block that generates reference data for moving robots. The “forward kinematic” block performs forward kinematic computation to convert data from joint space to workspace. DESIGNING HEDGE ALGEBRAIC CONTROLLER AND OPTIMIZING BY... 279 Some simulations with a 2-DOF serial robot arm which moves in the horizontal plane driven by 2 actuators are implemented. The numerical simulations are carried out in Simu- link. These trjectories include circle, spriral and square shapes. The results are shown in Figure 7 to Figure 12. Figure 6. Diagram of 2-DOF serial robot arm simulation to HAC Circle trajectory In this simulation, the center of the end effector will be moved along a circular trajectory, The trajectory has a center at (xC; yC) = (0.45;−0.45) [m] and radius R = 0.2 [m]. This trajectory is chosen to be in the task space of the robot. The starting point to move is (0.6022; -0.5127). Simulation results are shown in Figure 7 and Figure 8. Figure 7. The desired path vs. the actual path of the end effector with the circle path Figure 8. Tracking errors of x, y coordinates with the circle path Spiral trajectory In this simulation, the center of the end effector will be moved along a spiral trajectory, The trajectory has a center at (xC; yC) = (0.45;−0.45) [m] and the boundary radius R = 0.2 [m]. This trajectory is chosen to be in the task space of the robot. The starting point to 280 NGUYEN TIEN DUY, VU DUC VUONG move (0.6022; -0.5127). Simulatinon results are shown in Figure 9 and Figure 10. Figure 9. The desired path vs. the actual path of the end effector with the spiral path Figure 10. Tracking errors of x, y coordinates with the spiral path Square trajectory In this simulation, the center of the end effector will be moved along a square trajectory with the following coordinates A(0.65,−0.45); B(0.45,−0.25); C(0.25,−0.45); D(0.45,−0.65) (28) is at the starting point to move (0.6022; -0.5127). Simulation results are shown in Figure 11 and Figure 12. Figure 11. The desired path vs. the actual path of the end effector with the square path Figure 12. Tracking errors of x, y coordinates with the square path Simulation with noise DESIGNING HEDGE ALGEBRAIC CONTROLLER AND OPTIMIZING BY... 281 In this simulation, the center of the end effector will be moved along a spiral trajectory with the effection of noise. The result is shown in Figure 13. Figure 13. The desired path vs. the actual path of the end effector moves along the spiral path with noise It can be seen in Figure 7, the end effector of the robot moves from the initial position at the coordinate of (0.6022; -0.5127). The control trajectory of HAC is closer to the reference trajectory than the control trajectory by PID-Controller. Figure 8 shows the tracking error in the x and y directions by time is rapidly decreasing to the value which is close to 0 in the range of 0.5 [s] with one small overshoot/undershoot. Still at the original position at (0.6022; -0.5127), perform simulations with more complex trajectories such as Spiral Trajectory (Figure 9, Figure 10) and Square Trajectory (Figure 11, Figure 12). The control trajectory of HAC always gives deviations and response time is better than the control trajectory of the PID-controller. Simulated with the case of white noise impacting the angles q1 and q2 at the output of the robot with the spiral reference trajectory, the control trajectory of the HAC has a small fluctuation but does not lose control and still close to the trajectory reference (see Figure 13). The results show the efficiency of the hedge algebras controller optimized by GA with tracking control 2-DOF serial robot arm. 5. CONCLUSION In this study, we designed HAC for the 2-DOF serial robot arm. The controller has a fairly simple structure with a rule control system consisting of only 25 rules. The structure of hedge algebras for the input-output variables has only two hedges, including a negative hedge - Little and a positive hedge - Very. The controller has only 3 parameters that measure the fuzziness of the hedge. The application of available GA in Matlab to optimize these parameters is very effective. With the optimal set of parameters, through the simulation, it was found that HAC worked very well. This result shows that the potential of HAC application in robot control is very wide and 282 NGUYEN TIEN DUY, VU DUC VUONG promising. In the near future, we will expand the research on HAC applications for more complex robots such as robots with 3 degrees of freedom or higher, parallel robots, etc. Reference trajectories will be set up with many complex forms, with major turning points. Parameter optimization will also be performed in parallel and separately for each controller. REFERENCES [1] L. A. Tuan, S.-C. Moon, W. G. Lee, and S.-G. Lee, “Adaptive sliding mode control of overhead cranes with varying cable length”, J. Mech. Sci. Technol., vol. 27, no. 3, pp. 885–893, 2013. https://doi.org/10.1007/s12206-013-0204-x [2] M. Jouini, M. Sassi, N. Amara, and A. Sellami, “Modeling and control for a 6-DOF platform manipulator”, 2013 International Conference on Electrical Engineering and Software Ap- plications, Hammamet, 2013, pp. 1–5, doi: 10.1109/ICEESA.2013.6578432 [3] F. Piltan, N. Sulaiman, M. Rashidi, Z. Tajpaikar, and P. Ferdosali, “Design and implementation of sliding mode algorithm: Applied to robot manipulator - a review”, Int. J. Robot. Autom., vol. 2, no. 5, pp. 265–282, 2011. [4] F. Piltan and N. B. Sulaiman, “Review of sliding mode control of robotic manipulator”, World Appl. Sci. J., vol. 18, no. 12, pp. 1855–1869, 2012. [5] Siciliano and Khatib, Springer Handbook of Robotics. Springer, 2008. [6] D. Nguyen-Tuong, J. Peters, M. Seeger, and B. Scho¨lkopf, “Learning inverse dynamics: a com- parison”, in European Symposium on Artificial Neural Networks, no. EPFL-CONF-175477, 2008. [7] R. Isermann, “Adaptive control systems (A short review),” Digital Control Systems. Volume 2: Stochastic Control, Multivariable Control, Adaptive Control, Applications, R. Isermann, Ed. Berlin, Heidelberg: Springer Berlin Heidelberg, 1991, pp. 127–140. [8] Q. D. Le, H. Kang, and T. D. Le, “Adaptive extended computed torque control of 3 DOF planar parallel manipulators using neural network and error compensator”, Intelligent Computing Methodologies, Volume 9773, 2016, pp. 437–448. ISBN: 978-3-319-42296-1. [9] Y. Stepanenko and C.-Y. Su, “Adaptive motion control of rigid-link electrically-driven robot manipulators”, in Proceedings of the 1994 IEEE International Conference on Robotics and Automation, San Diego, CA, USA, 1994, pp. 630–635 vol.1. Doi: 10.1109/ROBOT.1994.351415 [10] F. L. Lewis, D. M. Dawson, and C. T. Abdallah, Control of Robot Manipulators. Prentice Hall PTR, 1993. [11] L. A. Zadeh, “Fuzzy sets,” Information and Control, vol. 8, no. 3, pp. 338–353, June 1965. [12] K. M. Passino, S. Yurkovich, and M. Reinfrank, Fuzzy control, vol. 20. Citeseer, 1998. https://www2.ece.ohio-state.edu/ passino/FCbook.pdf [13] C. G. Kang, “Variable structure fuzzy control using three input variables for redu- cing motion tracking errors”, J. Mech. Sci. Technol., vol. 23, pp. 1354–1364, 2009. https://doi.org/10.1007/s12206-009-0350-3 [14] D. Vukadinovic´, M. Basˇic´, C. H. Nguyen, N. L. Vu, and T. D. Nguyen, “Hedge-algebra-based voltage controller for a self-excited induction generator”, Control Engineering Practice, vol. 30, pp. 78–90, 2014. [15] C. H. Nguyen, D. A. Nguyen, and N. L. Vu, “Fuzzy controllers using hedge algebras based semantics of vague linguistic terms”, Fuzzy Control Syst. Nov. Sci. Publ. Hauppauge, 2013. pp. 135–192. DESIGNING HEDGE ALGEBRAIC CONTROLLER AND OPTIMIZING BY... 283 [16] N. D. Duc, N.-L. Vu, D.-T. Tran, and H.-L. Bui, “A study on the application of hedge algebras to active fuzzy control of a seism-excited structure”, J. Vib. Control, vol. 18, no. 14, pp. 2186–2200, 2012. [17] N. D. Anh, H. Bui, N. Vu, and D. Tran, “Application of hedge algebra-based fuzzy controller to active control of a structure against earthquake”, Struct. Control Heal. Monit., vol. 20, no. 4, pp. 483–495, 2013. [18] H.L. Bui, C.H. Nguyen, N.L. Vu, and C.H. Nguyen, “General design method of hedge-algebras- based fuzzy controllers and an application for structural active control”, Appl. Intell., vol. 43, no. 2, pp. 251–275, 2015. [19] N. V. Khang and C. A. My, Introduction to Robotic (in Vietnamese). Publishing House for Science and Technology, 2011. [20] N. V. Khang, Multibody System Dynamics (in Vietnamese). Publishing House for Science and Technology, 2007. [21] N. Van Khang, “Kronecker product and a new matrix form of Lagrangian equations with multi- pliers for constrained multibody systems”, Mech. Res. Commun., vol. 38, no. 4, pp. 294–299, 2011. [22] N. C. Ho and W. Wechler, “Hedge algebras: An algebraic approach to structure of sets of linguistic truth values”, Fuzzy sets Syst., vol. 35, no. 3, pp. 281–293, 1990. [23] N. C. Ho and W. Wechler, “Extended hedge algebras and their application to fuzzy logic”, Fuzzy Sets Syst., vol. 52, no. 3, pp. 259–281, 1992. [24] N. C. Ho, T. D. Khang, H. V. Nam, N. H. Chau, “Hedge algebras, linguistic- valued logic and their application to fuzzy reasoning”, International Journal of Un- certainty, Fuzziness and Knowledge-Based Systems, vol. 7, no. 4, pp. 347–361, 1999. https://doi.org/10.1142/S0218488599000301 [25] N.C.Ho, V.N.Lan and L.X.Viet, “Quantifying hedge algebra, interpolative reasoning method and its application to some problems of fuzy control”, Wseas Transactons on Computer, vol. 5, pp. 2519–2529, 2006. [26] N. C. Ho and N. V. Long, “Fuzziness measure on complete hedge algebras and quantifying semantics of terms in linear hedge algebras”, Fuzzy Sets Syst., vol. 158, no. 4, pp. 452–471, 2007. [27] N. T. Duy and N. T. Kien, “Designing the controller based on the approach of hedge alge- bras and optimization through genetic algorithm”, in International Journal of Electrical Electronics & Computer Science Engineering (IJEECSE), vol 5, no 2, pp. 189–194, 2018. https://www.ijeecse.com/V5N2-065.pdf [28] N. T. Duy, V.N.Lan, “Interpolation based on semantic distance weighting in hedge algebras and its application”, J. Comput. Sci. Cybern., vol. 33, no. 1, pp. 19–33, 2017. [29] M. Kumar, M. Husian, N. Upreti, and D. Gupta, “Genetic algorithm: Review and application”, Int. J. Inf. Technol. Knowl. Manag., vol. 2, no. 2, pp. 451–454, 2010. [30] D. H. T. Kim, T. N. Manh, C. N. Nhu, V. Do Hoang, and H. N. T. Thu, “Tracking control for electro-optical system in vibration enviroment based on self-tuning fuzzy sliding mode control,” J. Comput. Sci. Cybern., vol. 35, no. 2, pp. 185–196, 2019. [31] H. P. H. Anh and C. Van Kien, “Novel approach of robust hinf tracking control for uncertain fuzzy descriptor systems using parametric Lyapunov function,” J. Comput. Sci. Cybern., vol. 36, no. 1, pp. 69–88, 2020. Received on August 23, 2020 Revised on April 25, 2020

File đính kèm:

designing_hedge_algebraic_controller_and_optimizing_by_genet.pdf

designing_hedge_algebraic_controller_and_optimizing_by_genet.pdf